Self-heating type alcohol reforming hydrogen production micro channel reactor with micro-lug boss array structure

A technology for reforming hydrogen production and array structure, which is applied in the fields of hydrogen, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of improving hydrogen yield, simple structure, and easy bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

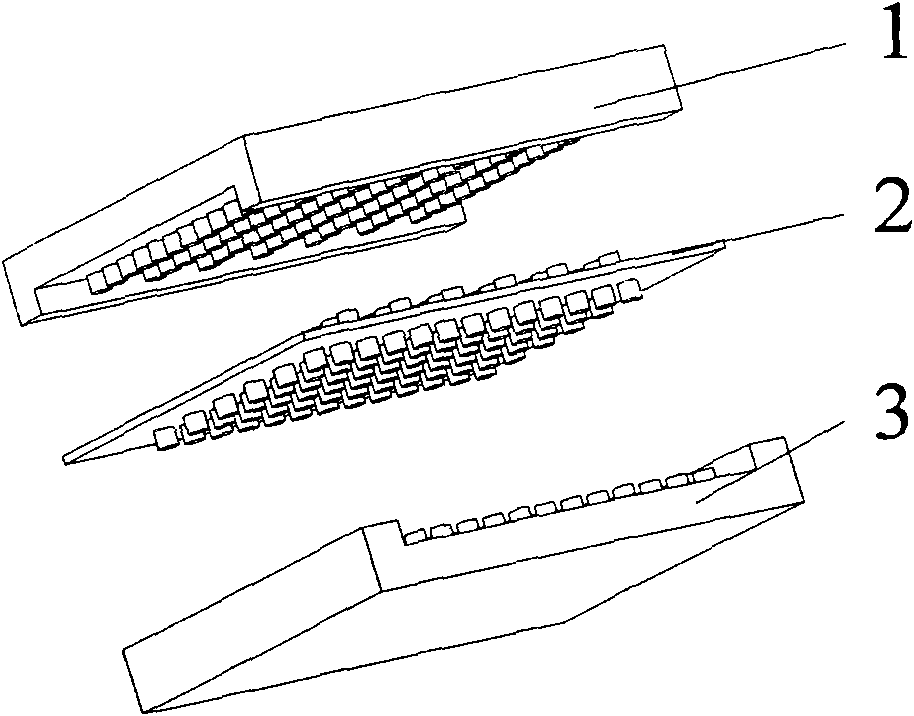

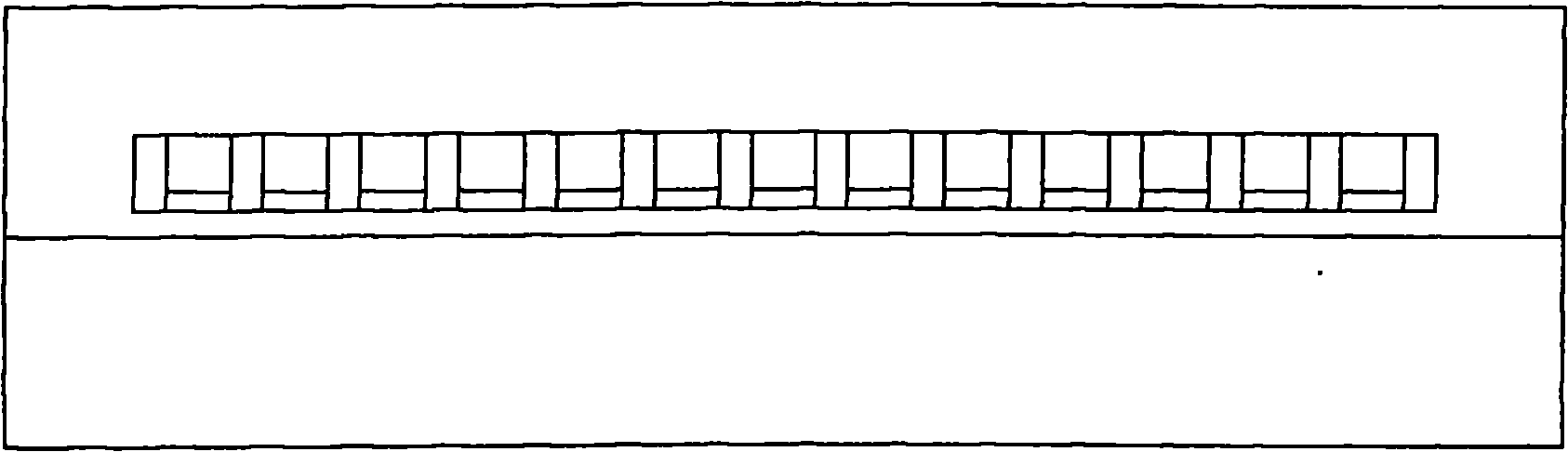

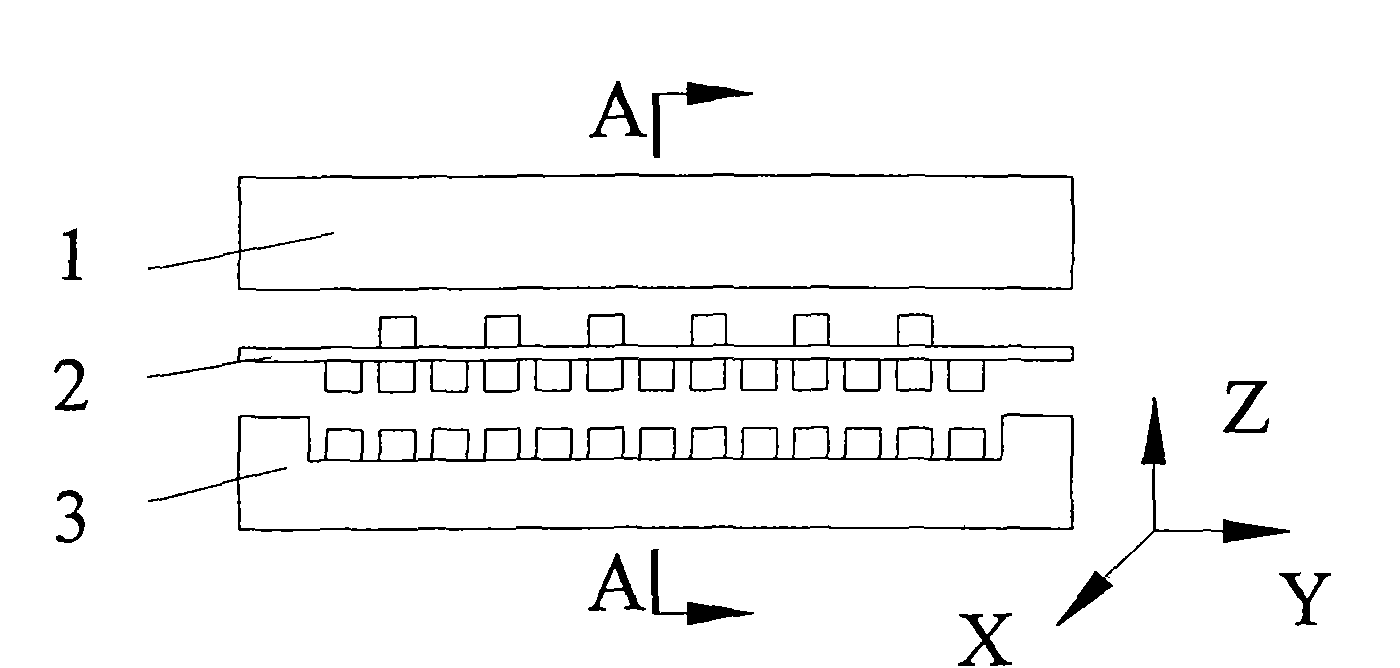

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the present invention comprises three-layer plate reaction carrier 1,2,3, as Figure 8 As shown, the X direction in the upper plate-shaped reaction carrier 1 with a concave cross-section in the Z direction is provided with micro-protrusion platforms distributed in an array of equal center spacing, the Y direction is micro-protrusion platforms distributed in an array of equal center spacing, and the X direction is slightly convex. The ratio of the platform to the center distance of the micro-protrusion platform in the Y direction is 1:2, and the height of the micro-protrusion platform is lower than the lower end surface of the plate-like reaction carrier 1 on the upper layer. Such as Figure 7 As shown, the upper end surface of the plate-shaped reaction carrier 2 in the middle layer is mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com