A processing method for controlling processing deformation of titanium-aluminum alloy thin-wall casing

A titanium-aluminum alloy and processing method technology, applied in the field of parts processing, can solve the problems of tool wear, large removal allowance, unsafe tool travel trajectory, etc., and achieve the effect of increasing the processing speed and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

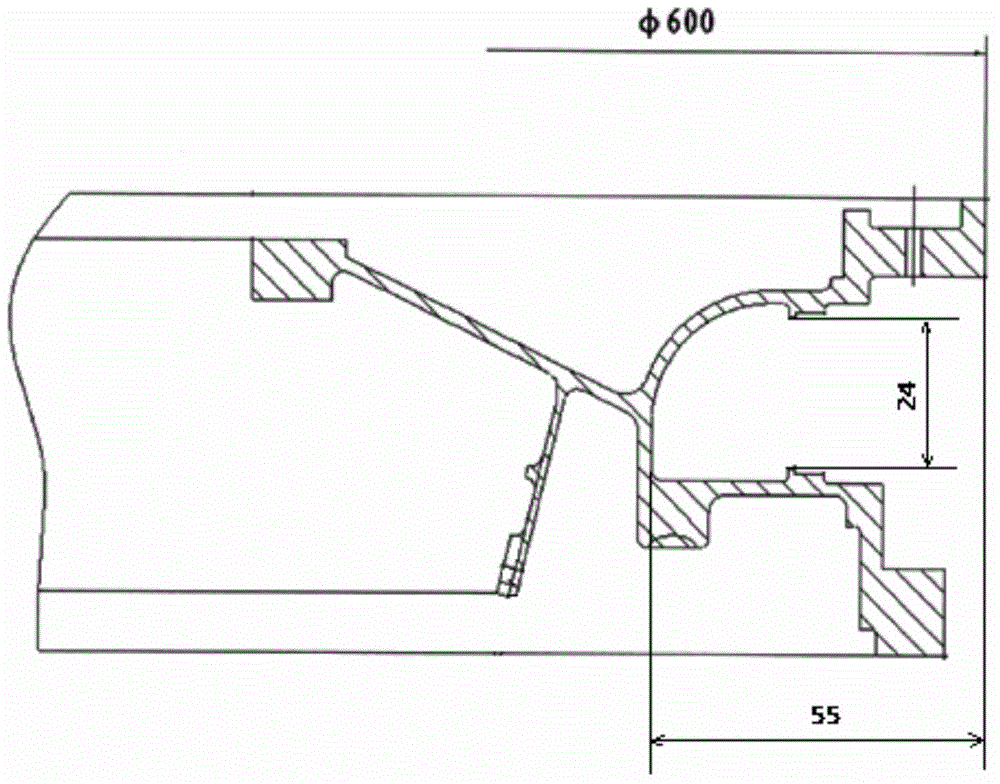

[0023] Such as figure 1 The shown titanium-aluminum alloy thin-walled casing, the outer circle is The finished groove on the outer wall has a groove depth of 55mm and a groove width of 24mm; the outer circle of the rough forging is

[0024] A processing method for controlling processing deformation of a titanium-aluminum alloy thin-wall casing, the processing method comprising the following steps:

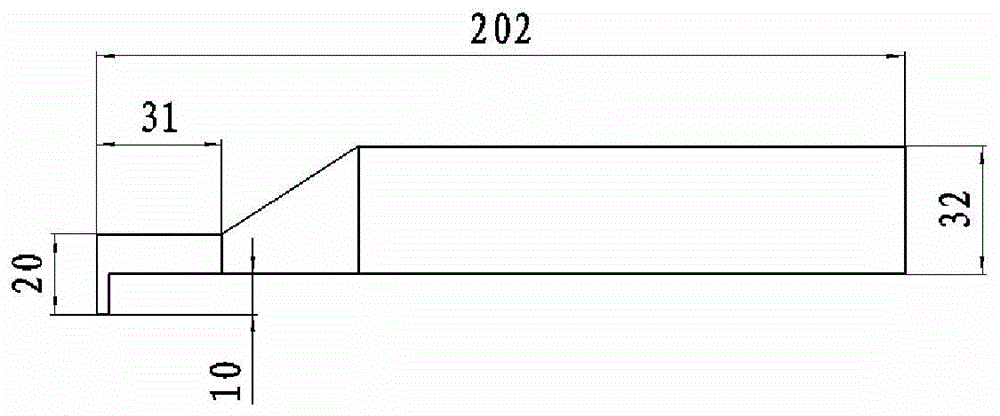

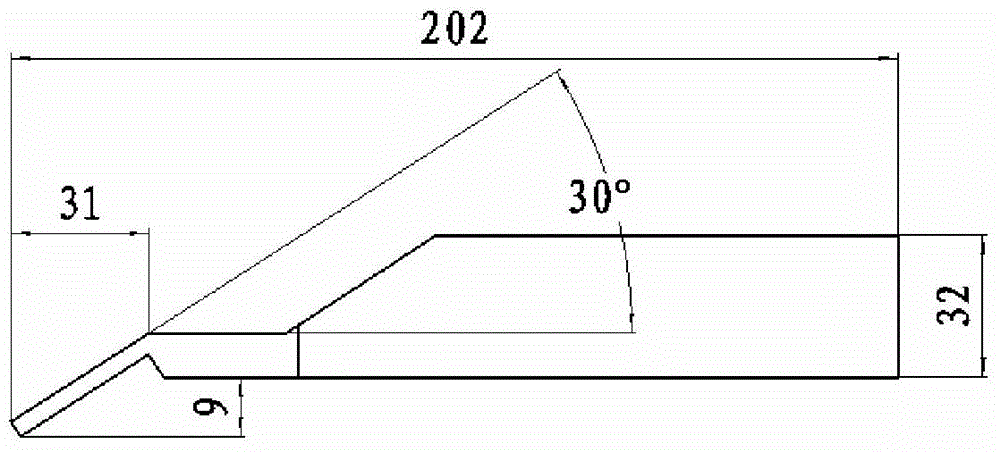

[0025] (1) Rough turning process one: process a straight groove on the outer wall of the titanium-aluminum alloy thin-walled casing forging to obtain a rough-machined semi-finished product; the groove depth of the straight groove is 40 mm, and the groove width is 16 mm; The process parameters of the straight groove are: speed n=8r / min, feed rate f=0.1mm / r, depth of cut ap=6mm, using a welding turning tool, and the material of the turning tool is YD15;

[0026] (2) Heat treatment step 1: heat-treat the rough-processed semi-finished product, the quenching temperature is 1060°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com