Preparation method for loading titanium dioxide (TiO2) nano fiber photocatalyst on basalt cellucotton substrate

A basalt fiber and nanofiber technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of restricting the industrialization of photocatalysts, difficulty in recycling and reuse, and large loss of active components, and achieve cost Low cost, simple preparation method and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] TiO loaded on a basalt fiber cotton matrix 2 The preparation method of nanofiber photocatalyst, the method step is as follows,

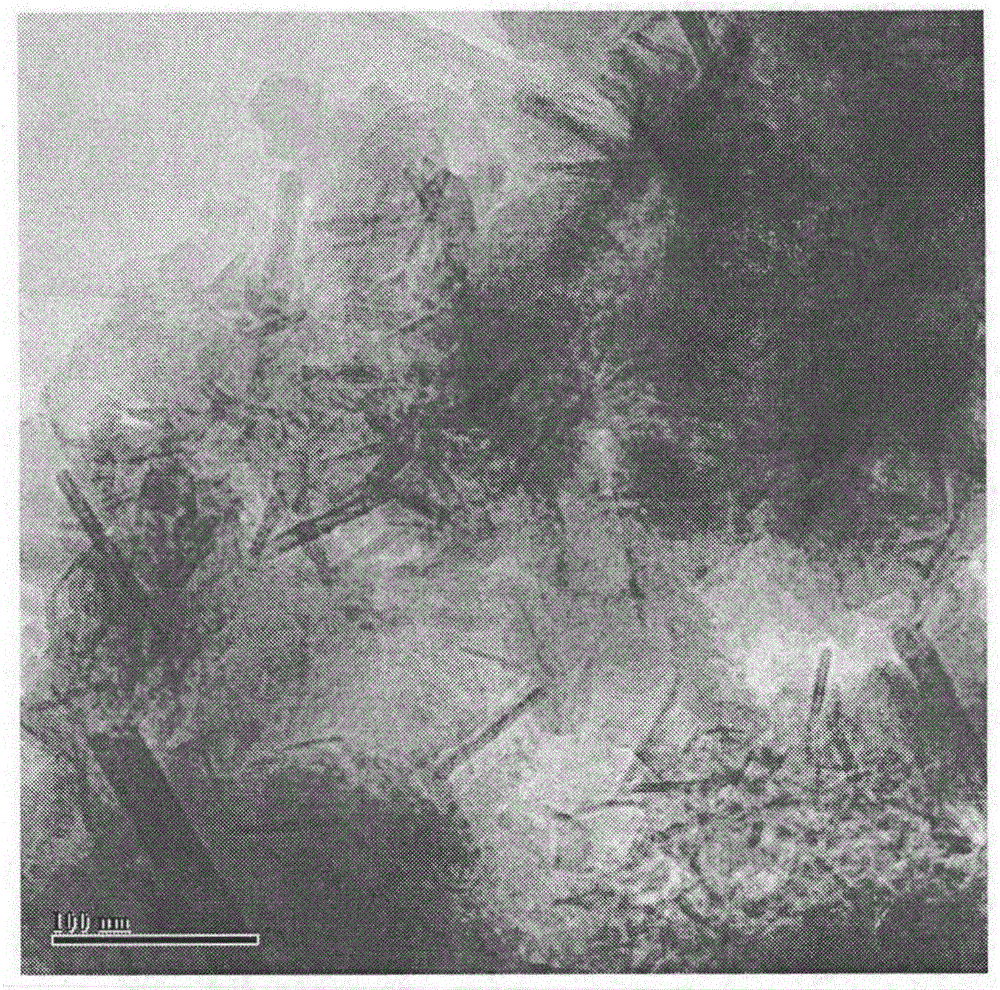

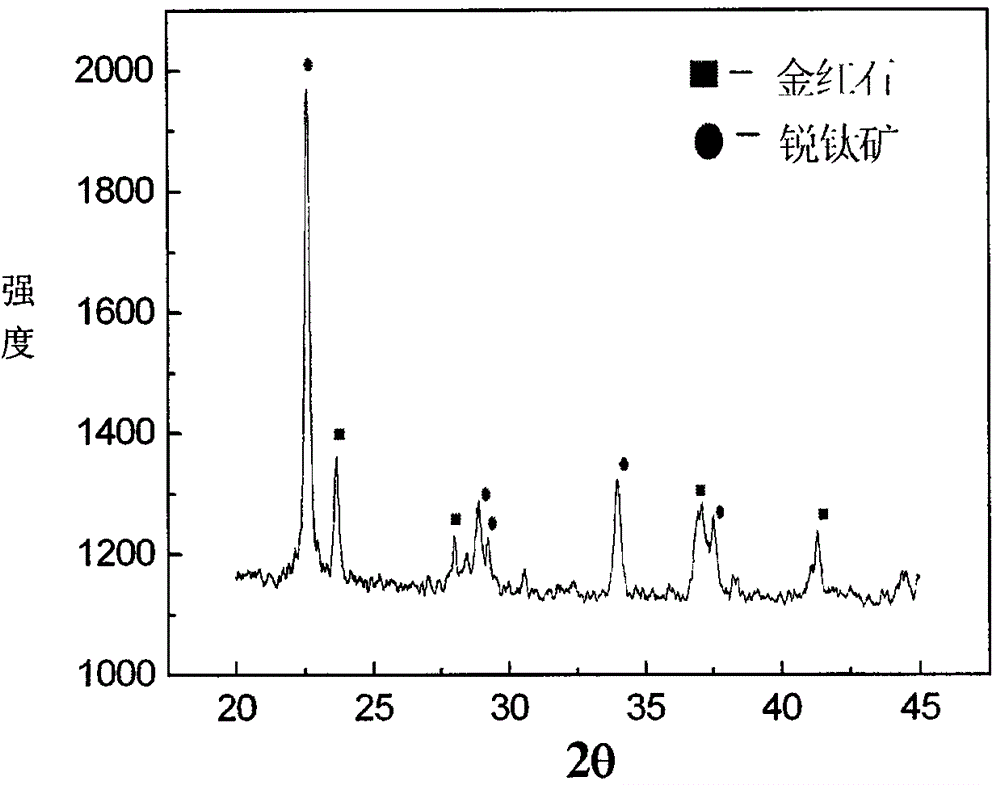

[0026] Weigh 50ml of tetrabutyl titanate, stir at 60°C, add nitric acid dropwise at a rate of 1 drop per minute to the mixture until pH = 4, stir evenly for 30min to obtain a transparent red solution, then add polyvinylpyrrolidone PVPk90 (the amount of polyvinylpyrrolidone used is 9% of the total mass of the solution) was stirred for 4 hours to fully dissolve and evenly, and then stood still for 1 hour to obtain a transparent precursor solution. The PVP / TiO was prepared by spinning at an ambient temperature of 20 °C, a humidity of 40%, a curing distance of 18 cm, and a horizontal and lateral inclination angle of PTFE needle and stainless steel needle at 16°. 2 Composite fiber, stainless steel electrode is used as the conductive rod of spinning solution, and the negative electrode receiving device is basalt fiber cotton with electroless nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com