Double-principal-phase yttrium-contained permanent magnet and preparing method of double-principal-phase yttrium-contained permanent magnet

A dual main-phase, permanent magnet technology, applied in the manufacture of magnetic objects, permanent magnets, inductors/transformers/magnets, etc., can solve the problem that the B magnet cannot meet the performance requirements, achieve high component adjustable degrees of freedom, and improve cost performance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

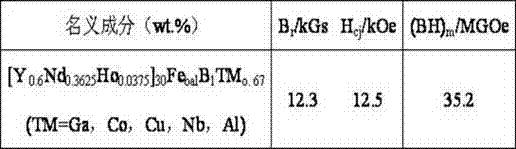

[0028] According to the preparation method of the present invention, the composition according to the design is [Y 0.6 Nd 0.3625 Ho 0.0375 ] 30 Fe bal B1 tm o. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%) double main phase yttrium-containing permanent magnet, the specific steps are as follows:

[0029] (1) Prepare two different main phase alloys, according to the composition of the first main phase alloy, the mass percentage is Nd 30 Fe bal B 1 tm 0. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), the composition of the second main phase alloy is [Y 0.8 Nd 0.15 Ho 0.05 ] 30 Fe bal B 1 tm 0.67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), prepare raw materials respectively;

[0030] (2) The prepared raw materials are smelted as follows: first, put the raw materials into the crucible of the medium frequency induction melting furnace, and when the vacuum degree reaches 10 -2 Preheat with low power when Pa is above, and wait until the vacuum degree reaches 10 again. -2 Stop vacuuming and fill high-...

Embodiment 2

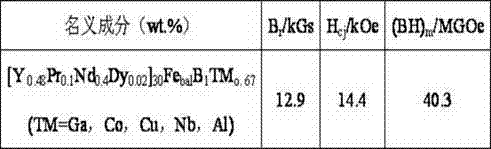

[0040] According to the preparation method of the present invention, the composition according to the design is [Y 0.48 PR 0.1 Nd 0.4 Dy 0.02 ] 30 Fe bal B 1 tm o. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%) double main phase yttrium-containing permanent magnet, the specific steps are as follows:

[0041] (1) Prepare two different main phase alloys, the composition of the first main phase alloy is (Pr 0.25 Nd 0.75 ) 30 Fe bal B 1 tm 0. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), the composition of the second main phase alloy is [Y 0.8 Nd 0.167 Dy 0.033 ] 30 Fe bal B 1 tm 0.67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), prepare raw materials respectively;

[0042] (2) The prepared raw materials are smelted as follows: first, put the raw materials into the crucible of the medium frequency induction melting furnace, and when the vacuum degree reaches 10 -2 Preheat with low power when Pa is above, and wait until the vacuum degree reaches 10 again. -2 Stop vacuuming and fill high-purity A...

Embodiment 3

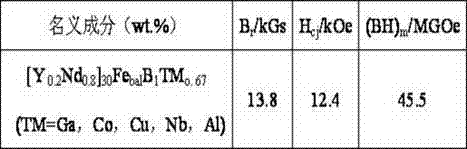

[0052] According to the preparation method of the present invention, the composition according to the design is [Y 0.2 Nd 0.8 ] 30 Fe bal B 1 tm o. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%) double main phase yttrium-containing permanent magnet, the specific steps are as follows:

[0053] (1) Prepare two different main phase alloys, the composition of the first main phase alloy is Nd by mass percentage 30 Fe bal B 1 tm 0. 67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), the composition of the second main phase alloy is (Y 0.3 Nd 0.7 ) 30 Fe bal B 1 tm 0.67 (TM=Ga, Co, Cu, Nb, Al) (wt.%), prepare raw materials respectively;

[0054] (2) The prepared raw materials are smelted as follows: first, put the raw materials into the crucible of the medium frequency induction melting furnace, and when the vacuum degree reaches 10 -2 Preheat with low power when Pa is above, and wait until the vacuum degree reaches 10 again. -2 Stop vacuuming and fill high-purity Ar after the Pa is above, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com