Well drilling five-cylinder pump and method for installing helical gears thereof

A technology of helical gears and pinions is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problems of difficult installation and removal of gears, large pulsation, and large force on the support bearing 06. To achieve the effect of convenient disassembly and assembly, no stress concentration, and convenient relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

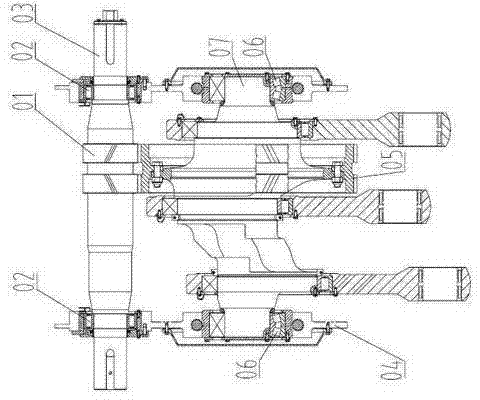

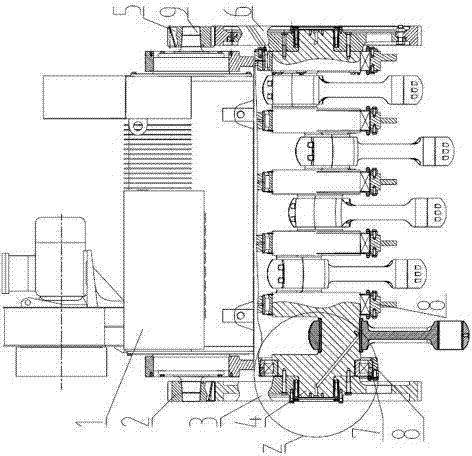

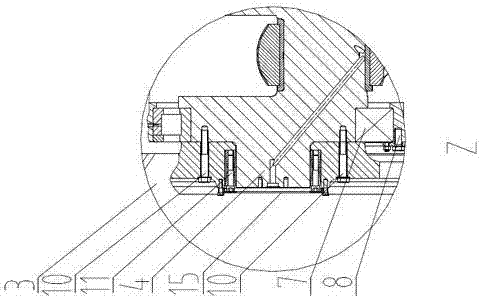

[0039] Such as figure 2 Of Figure 7As shown in one of them, a five-cylinder pump for oil drilling of the present invention includes a frame 8, a crankshaft 4 arranged on the frame 8, a motor 1 fixed on the frame 8, and a pinion shaft 9 connected with the motor 1 The two ends of described pinion shaft 9 are respectively provided with pinion 2,5; All are provided with the bearing 7 of support crankshaft 4 on the crankshaft 4 between each cylinder of described five-cylinder pump; The two ends of described crankshaft 4 There are two helical gears 3, 6, and the tooth shapes of the two helical gears 3, 6 have opposite directions of rotation, and the helical gears 3, 6 and the crankshaft 4 are connected by an expansion sleeve 11; the helical gear 3 , 6 is provided with a stepped hole 12 on the end surface, the large hole 13 of the stepped hole 12 is the installation hole of the expansion sleeve 11, the small hole 14 of the stepped hole 12 is the installation positioning hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com