Device and method for preparing boron nitride single crystal

A boron nitride single crystal, boron nitride technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of irregular shape, can not meet the needs of research and industrial development, etc., to achieve cost Low, corrosion avoidance, material availability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

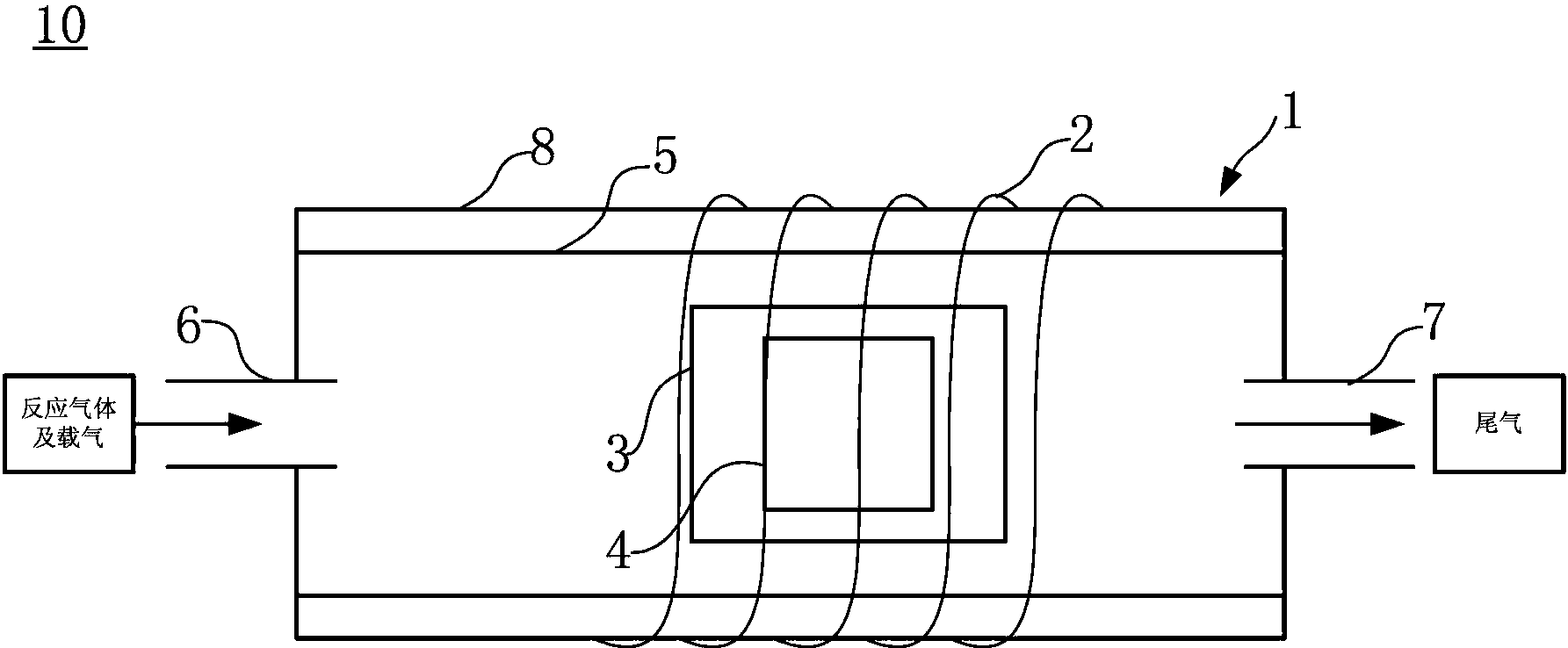

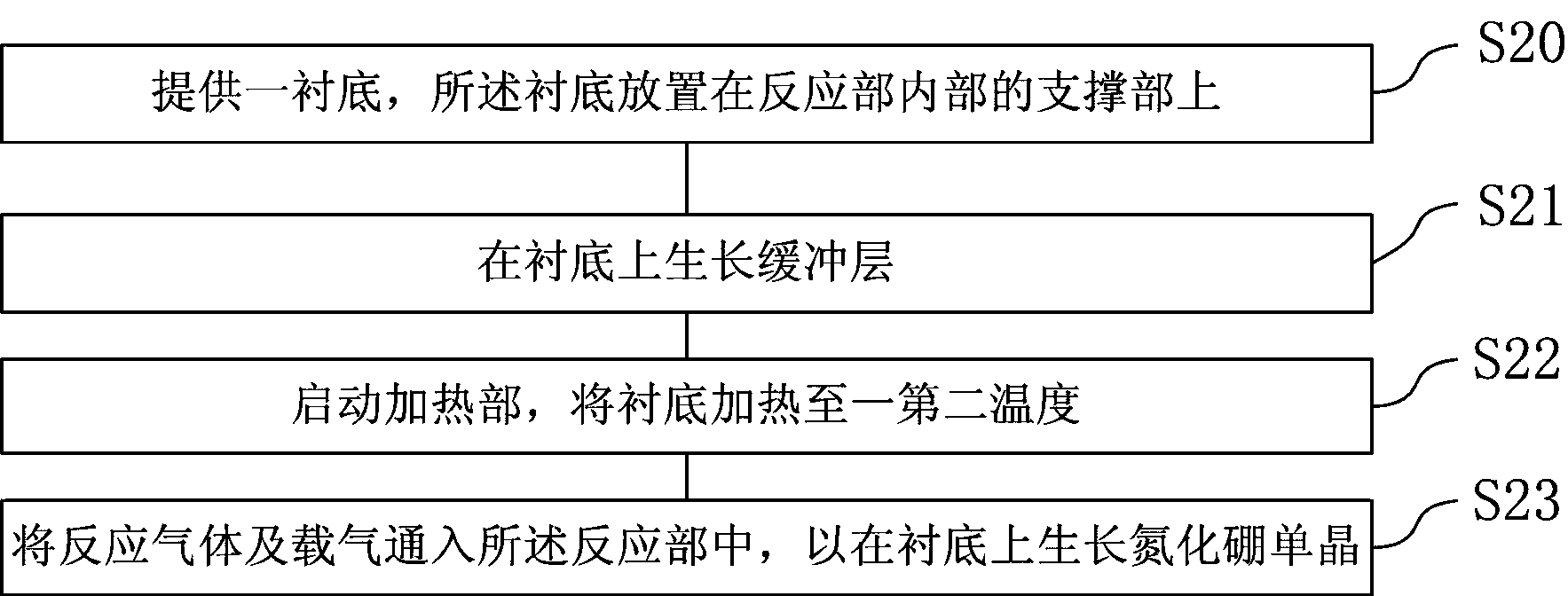

[0044]In the first embodiment, sapphire is used as a substrate, boron trichloride and ammonia are used as reaction gases, and nitrogen and hydrogen are used as carrier gases to grow a boron nitride single crystal. The boron nitride single crystal preparation method is as follows:

[0045] (1) Provide a sapphire substrate 4, the sapphire substrate 4 is placed on the support part 3 in the reaction part 1;

[0046] (2) Passing alternating current into the heating part 2, and using electromagnetic induction to heat the sapphire substrate 4 to a first temperature, and the first temperature is 900°C;

[0047] (3) Boron trichloride and ammonia are used as reaction gases, and nitrogen and hydrogen are used as carrier gases to pass into the reaction part 1 through the gas inlet 6 to grow a boron nitride single crystal on the sapphire substrate 4 The buffer layer is kept warm at the first temperature for some time. In the present embodiment 1, the boron nitride buffer layer formed has...

Embodiment 2

[0050] In the second embodiment, silicon is used as a substrate, boron trichloride and ammonia are used as reaction gases, and nitrogen and hydrogen are used as carrier gases to grow a boron nitride single crystal. The boron nitride single crystal preparation method is as follows:

[0051] (1) Provide a silicon substrate 4, the silicon substrate 4 is placed on the support part 3 in the reaction part 1;

[0052] (2) Apply alternating current to the heating part 2, and use electromagnetic induction to heat the silicon substrate 4 to a first temperature, and the first temperature is 900°C;

[0053] (3) Boron trichloride and ammonia are used as reaction gases, and nitrogen and hydrogen are used as carrier gases to pass into the reaction part 1 through the gas inlet 6 to grow a boron nitride single crystal on the silicon substrate 4 The buffer layer is kept warm at the first temperature for some time. In Example 2, the thickness of the formed boron nitride buffer layer was 500 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com