Method for preparing nanosilver/silicon dioxide composite structure coating through pulsed laser deposition

A pulsed laser deposition and silicon dioxide technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of introducing impurities and many kinds of chemical raw materials, and achieve short generation cycle and novel synthesis method. , Antibacterial effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

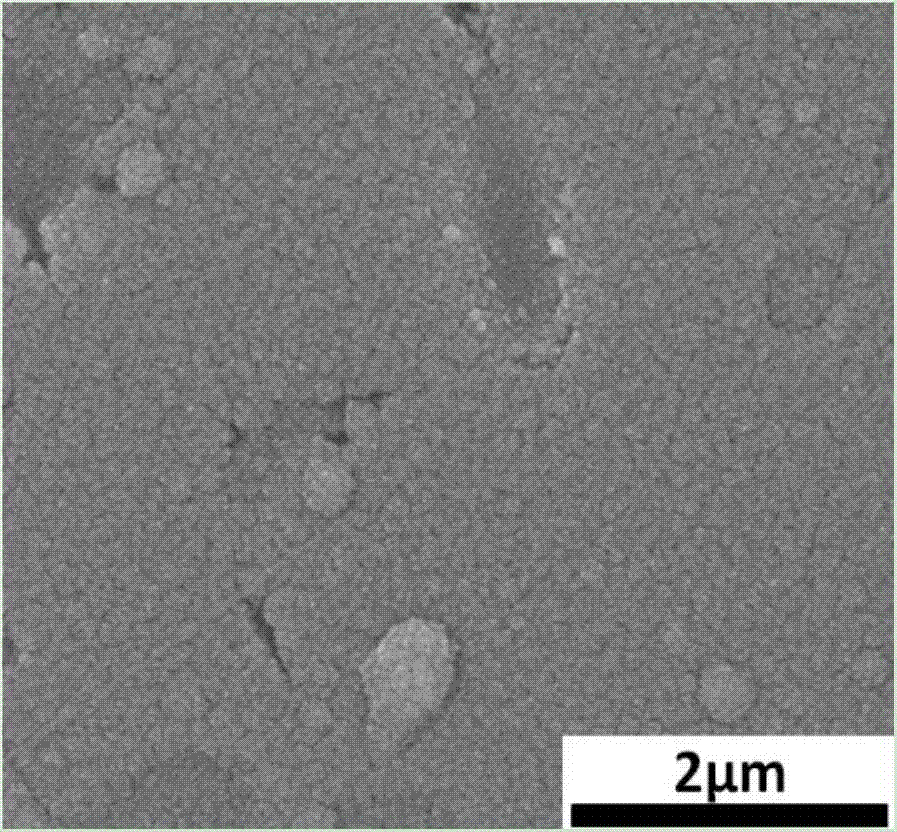

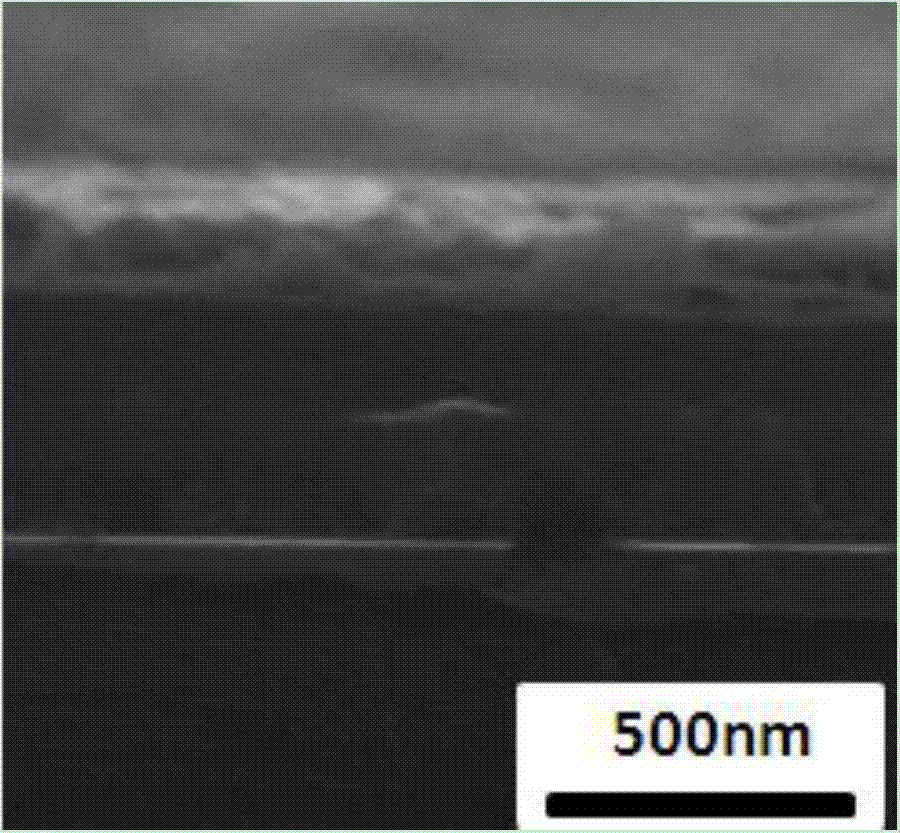

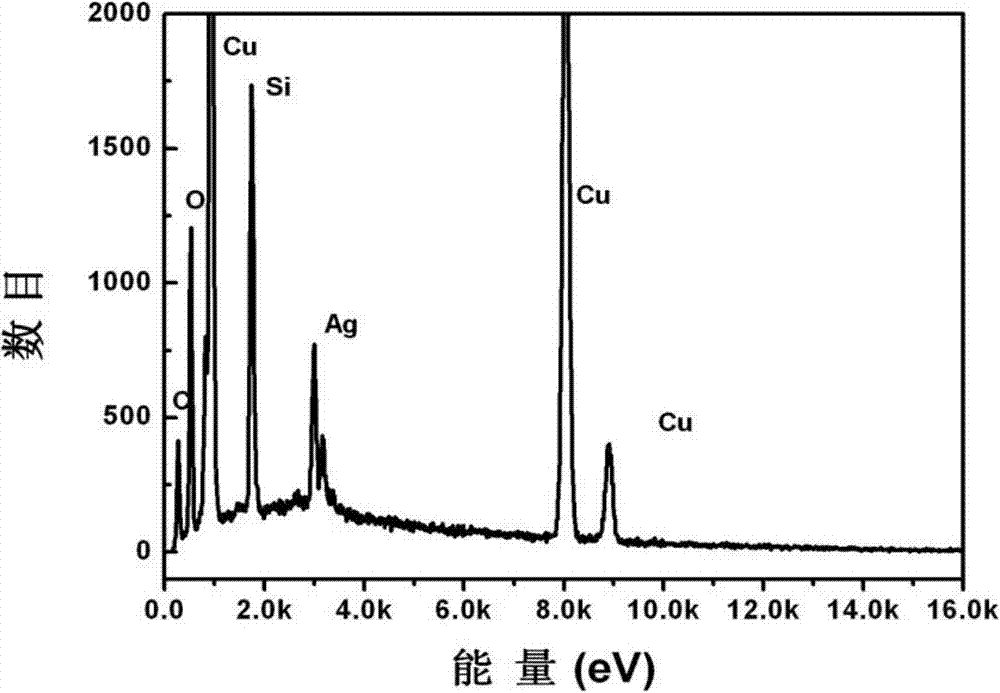

[0032] Specific embodiment one: In this embodiment, a method for preparing a nano-silver / silicon dioxide composite structure coating by pulsed laser deposition is carried out according to the following steps:

[0033] 1. Preparation of silver / silicon dioxide composite target material: Silica powder with a purity of 99.9% is pressed into a silicon dioxide disc with a diameter of 10 mm to 100 mm and a thickness of 1 mm to 10 mm under a pressure of 20 MPa. The temperature is 1200℃~1600℃ for sintering, the sintering time is 1h~10h, and then the 7mm 2 ~6300mm 2 The pure silver sheet is fixed on the sintered silicon dioxide disc to obtain a silver / silicon dioxide composite target; the pure silver sheet accounts for 10% to 90% of the area of the silver / silicon dioxide composite target;

[0034] 2. Cleaning the substrate: The substrate is ultrasonically cleaned once with acetone, deionized water and methanol as a cycle, and the cleaning is repeated for 2 to 3 cycles to obtain the c...

specific Embodiment approach 2

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the silicon dioxide disc with a diameter of 30 mm and a thickness of 3 mm is pressed. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, sintering is carried out at a temperature of 1280°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com