FD bearing oil composition, preparation method and applications thereof

A kind of composition and bearing oil technology, applied in the field of materials, can solve the problems of bearing failure, reduce equipment utilization, increase maintenance costs, etc., and achieve the effects of extending service life, saving consumption, and reducing the incidence of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ① Grind boehmite to particle size ≤ 1 μm, and dry at 200°C for 2 hours; crush chlorite to particle size ≤ 100nm, and dry at 100°C for 1 hour;

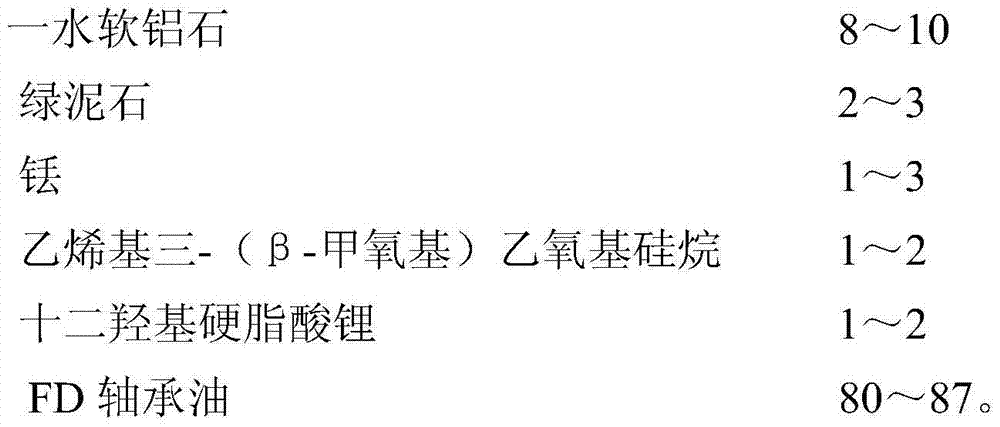

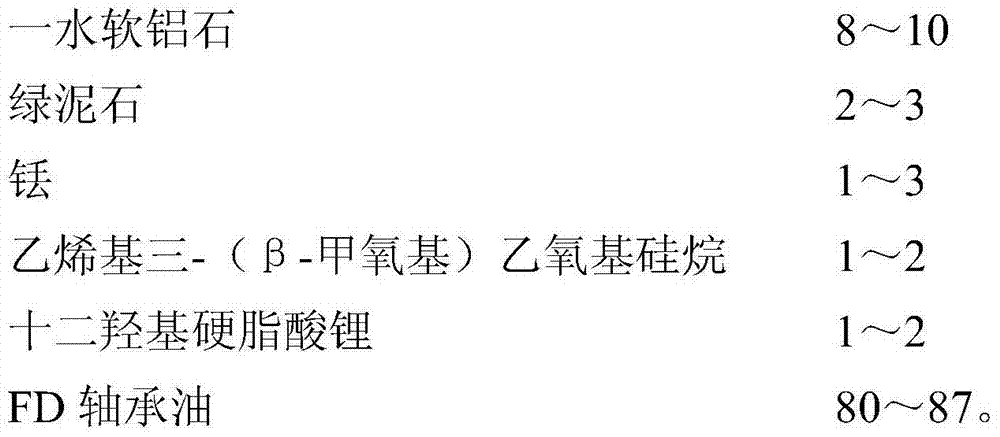

[0030] ②Weigh 8g of boehmite obtained in step ①, 2g of chlorite, 1g of thulium, 1g of vinyl tris-(β-methoxy)ethoxysilane, lithium dodecyl hydroxystearate in parts by mass 1g and 87g of FD bearing oil are mixed and added to the closed device to make the vacuum degree reach -0.08MPa;

[0031] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0032] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0033] The prepared FD bearing oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 700N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the worn surface of the sample is HV1153. The sample changed fro...

Embodiment 2

[0035] ① Grind boehmite to a particle size of ≤5 μm, and dry at 210°C for 2 hours; crush chlorite to a particle size of ≤100nm, and dry at 100°C for 1 hour;

[0036] ②Weigh 9g of boehmite obtained in step ①, 2.5g of chlorite, 2g of thulium, 1.5g of vinyl tris-(β-methoxy)ethoxysilane, dodecyl hydroxy stearate in parts by mass Lithium oxide 1.5g, FD bearing oil 83.5g are mixed and added into the closed device to make the vacuum degree reach -0.08MPa;

[0037] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0038] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0039] The prepared FD bearing oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 700N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the worn surface of the sample is HV1195. The...

Embodiment 3

[0041] ① Grind boehmite to a particle size of ≤5 μm, and dry at 210°C for 2 hours; crush chlorite to a particle size of ≤100nm, and dry at 100°C for 1 hour;

[0042] ②In parts by mass, weigh 10g of boehmite obtained in step ①, 3g of chlorite, 3g of thulium, 2g of vinyl tris-(β-methoxy)ethoxysilane, lithium dodecyl hydroxystearate 2g and 80g of FD bearing oil are mixed and added to the closed device to make the vacuum degree reach -0.08MPa;

[0043] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0044] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0045] The prepared FD bearing oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 700N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the worn surface of the sample is HV1116. The sample c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com