Colored glaze ceramic tile, production method of colored glaze ceramic tile, and forming device using production method

A technology of ceramic tiles and colored glazes, which is applied in the field of building roofing materials, can solve the problems of undisclosed raw materials and their proportions and molding devices, affecting the uniform thickness effect, and difficulty in guaranteeing the quality of colored glazed ceramic tiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

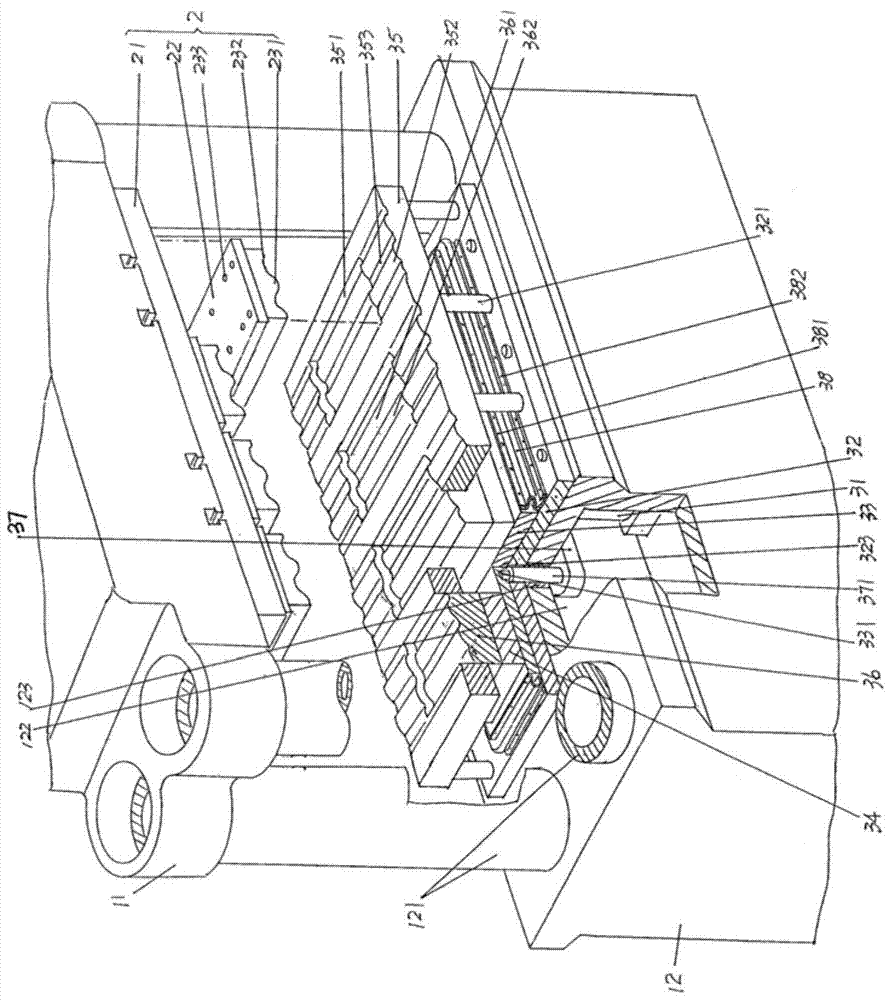

Image

Examples

Embodiment 1

[0035] A) Raw material preparation, take 40% of clay, 14.5% of quartz sand, 15% of porcelain stone, 30% of potassium feldspar and 0.5% of sodium humate according to the mass percentage to obtain raw materials;

[0036] B) Ball milling pulping, introduce the raw materials obtained in step A) into the ball mill and add water for ball milling, the speed of the ball mill is controlled at 10rpm, the ball milling time is controlled at 8h, the weight ratio of ball stones to raw materials is controlled at 1.6:1, and the diameter is 3-5 The ball stones with a diameter of 6-8 cm account for 70% of the total weight of the ball stones, the ball stones with a diameter of 6-8 cm account for 20% of the total weight of ball stones, and the ball stones with a diameter of 9-12 cm account for 10% of the total weight of ball stones. The sieve that obtains the slurry that moisture content is 38%;

[0037]C) Spray powder making, the slurry obtained in step B) is sent to the drying tower in the form...

Embodiment 2

[0062] A) Raw material preparation, according to mass percentage, kaolin 29.85%, quartz sand 20%, wollastonite 2.5%, magnesia mud 2.5%, potassium feldspar 15%, albite 15%, anorthite 10% %, barium feldspar 5% and sodium metasilicate 0.15%, obtain raw material;

[0063] B) Ball milling pulping, introduce the raw materials obtained in step A) into the ball mill and add water for ball milling, the speed of the ball mill is controlled at 12rpm, the ball milling time is controlled at 6h, the weight ratio of ball stones and raw materials is controlled at 1.5:1, and the ball mill is passed through 35 Purpose sieve, obtain the slurry that moisture content is 33%;

[0064] C) Spray pulverization, the slurry obtained in step B) is sent to the drying tower in the form of mist under the pressure of the slurry pump to be 1.2MPa by the slurry pump, and the drying temperature of the drying tower is controlled at 750°C After drying, a powder with a moisture content of 6% is obtained. After th...

Embodiment 3

[0070] A) raw material preparation, take kaolin 18%, montmorillonite 18%, quartz sand 10.65%, high alumina bauxite 10%, albite 43% and sodium tripolyphosphate 0.35% by mass percentage to obtain raw materials;

[0071] B) Ball milling pulping, introduce the raw materials obtained in step A) into the ball mill and add water for ball milling, the speed of the ball mill is controlled at 15rpm, the ball milling time is controlled at 5h, the weight ratio of ball stones and raw materials is controlled at 1.8:1, and the ball mill is passed through 30 Purpose sieve, obtain the slurry that moisture content is 35%;

[0072] C) Spray powder making, the slurry obtained in step B) is sent to the drying tower in the form of mist under the pressure of the slurry pump to be 1 MPa by the slurry pump, and the drying temperature of the drying tower is controlled at 700 ° C. After drying, the powder with a moisture content of 7% is obtained. After the powder leaves the drying tower, it is introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com