Combined type reverse dimming device of light path of laser cutting machine

A technology of laser cutting machine and dimming device, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing the difficulty of dimming, consuming manpower and time, and increasing the cost and maintenance cost of the cutting machine. , to achieve the effect of fast and reliable dimming, low power consumption and saving dimming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

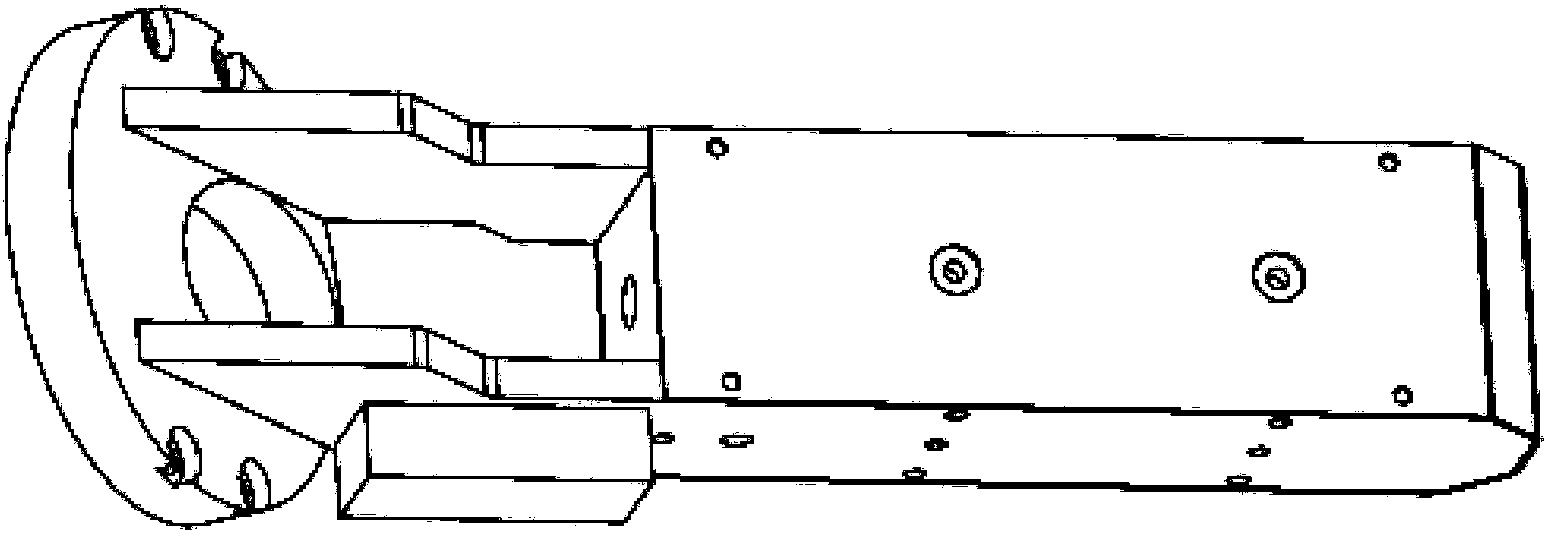

[0026] see figure 1 , a combined reverse dimming device for the optical path of a laser cutting machine of the present invention is composed of an indicating light emitter, an adjustable mirror base dimming cylinder, a Y-axis mirror base dimming cylinder, and a compensation mirror base dimming cylinder, wherein:

[0027] The indicator light transmitter emits the indicator light with the same frequency, wavelength and pulse width as the cutting machine laser. Because of its small size, light weight, and convenient adjustment, and the external dimensions of its aluminum alloy shell mounting position are the same as those of the adjustable lens, it can be installed on the adjustable mirror holder and mirror cavity.

[0028] The structure of the adjustable mirror base dimmer, the Y-axis mirror base dimmer, and the compensation mirror base dimmer all have a 1.5mm small hole on the end surface of the shaft, and are concentric with the shaft. When the light tube is installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com