One-step forming straight welding method for stainless steel outer composite tubes

A technology of stainless steel and composite pipes, applied in welding equipment, welding/welding/cutting articles, tubular articles, etc., can solve the problems of high welding cost, labor and time-consuming, easy to rust, etc., and achieve simple welding method, less consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weld the 3mm thick stainless steel composite round tube blank with the grade of SUS304+Q235, in which the thickness of the carbon steel base layer is 2.7mm, and the thickness of the outer stainless steel cladding layer is 0.3mm. The chemical composition of the stainless steel cladding layer is shown in Table 1; the selected diameter is Φ1.0mm CHW-308 stainless steel welding wire, the chemical composition of the welding wire is shown in Table 2, the flux is CHF260, and the chemical composition of the flux is shown in Table 3;

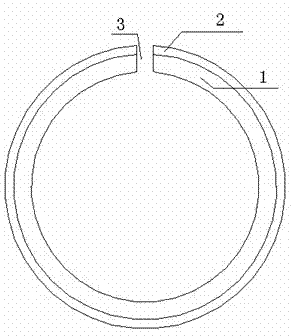

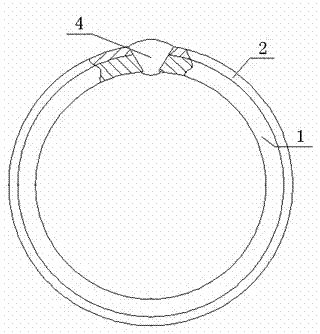

[0015] And under the following conditions: the groove gap of the tube blank is 0.8-1.5 mm, the distance from the welding torch contact tip to the tube is 13-23 mm, the distance from the welding wire to the tube is 1.0-2.0 mm, the welding current is 300A, and the welding voltage is 35V , the welding speed is 1.1m / min, the welding wire feeding speed is 15 m / min, and the groove of the tube blank is welded once, such as figure 1 , figure 2 , The wel...

Embodiment 2

[0017] Weld the 5mm-thick stainless steel composite square tube billet of SUS304+Q235, in which the thickness of the carbon steel base layer is 4.5mm, and the thickness of the outer stainless steel layer is 0.5mm. The chemical composition of the stainless steel layer is shown in Table 1; the selected diameter is Φ1.0mm CHW-308 stainless steel welding wire, the chemical composition of the welding wire is shown in Table 2, the flux is CHF260, and the chemical composition of the flux is shown in Table 3;

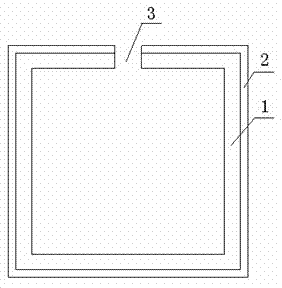

[0018] And under the following conditions: the groove gap of the tube blank is 0.8-1.5 mm, the distance from the welding torch tip to the tube is 13-23 mm, the distance from the welding wire to the tube is 1.0-2.0 mm, the welding current is 330A, and the welding voltage is 45V , the welding speed is 1m / min, the welding wire feeding speed is 25 m / min, and the groove of the tube blank is welded once, such as image 3 , Figure 4 , The weld has passed the 170-hour salt spray test...

Embodiment 3

[0020] Weld the 7mm thick stainless steel composite round tube billet of grade SUS304+Q235, in which the thickness of the carbon steel base layer is 6.3mm, and the thickness of the outer stainless steel cladding layer is 0.7mm. The chemical composition of the stainless steel cladding layer is shown in Table 1; the selected diameter is Φ1.6mm CHW-308L stainless steel welding wire, the chemical composition of the welding wire is shown in Table 4; the flux is CHF260, and the chemical composition of the flux is shown in Table 3;

[0021] And under the following conditions: the groove gap of the tube blank is 0.8-1.5 mm, the distance from the welding torch contact tip to the tube is 13-23 mm, the distance from the welding wire to the tube is 1.5-2.5 mm, the welding current is 330A, and the welding voltage is 47V , the welding speed is 0.9 m / min, the welding wire feeding speed is 30 m / min, and the groove of the tube blank is welded once, such as figure 1 , figure 2 , The weld has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com