Automatic welding equipment

An automatic welding and equipment technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the welding effect cannot be guaranteed, the welder is tired during the welding process, and the output is not high, and the welding method is simple and the welding The effect of improving yield and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

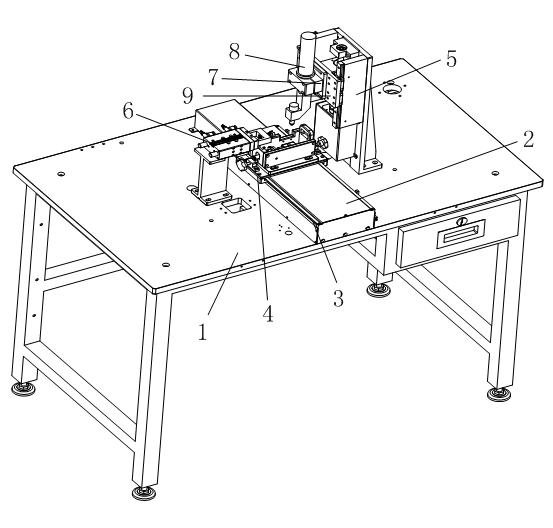

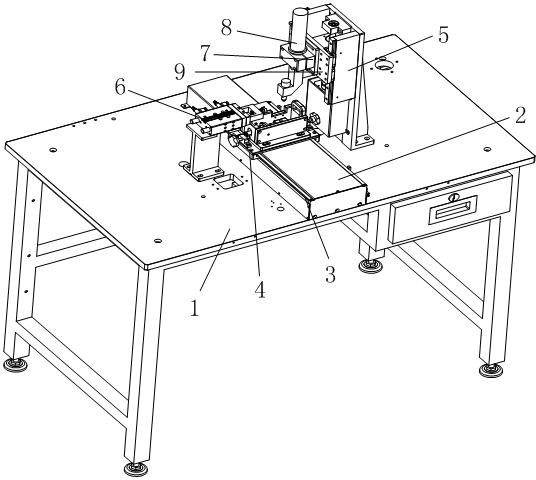

[0010] Such as figure 1 As shown, the automatic welding equipment is equipped with a sliding table 2 on the operating table 1. The sliding table 2 is fixed in the operating area of the operating table 1. There are grooves 3 on both sides of the sliding table 2, and the sliding table 1 passes through the groove. 3 is equipped with a movable fixed seat 4; the side of the sliding table 2 with the groove 3 is provided with a welding machine grounding protection mechanism 6, and the other side of the sliding table 2 is provided with a welding torch sliding table mechanism 5 perpendicular to the sliding table 2, The two are located at the center line of the slide table 2, the two are fixed on the slide table operating table 1, and the distance between the two and the sides of the slide table 2 is equal, the welding machine grounding protection mechanism 6 and the welding torch slide table mechanism 5 Relatively aligned; the welding torch mechanism 5 is provided with a welding torc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com