Lead battery

A technology of lead-acid batteries and battery tanks, which is applied in the direction of lead-acid batteries, lead-acid battery construction, lead-acid battery electrodes, etc., to achieve the effect of improving insufficient charging and preventing stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

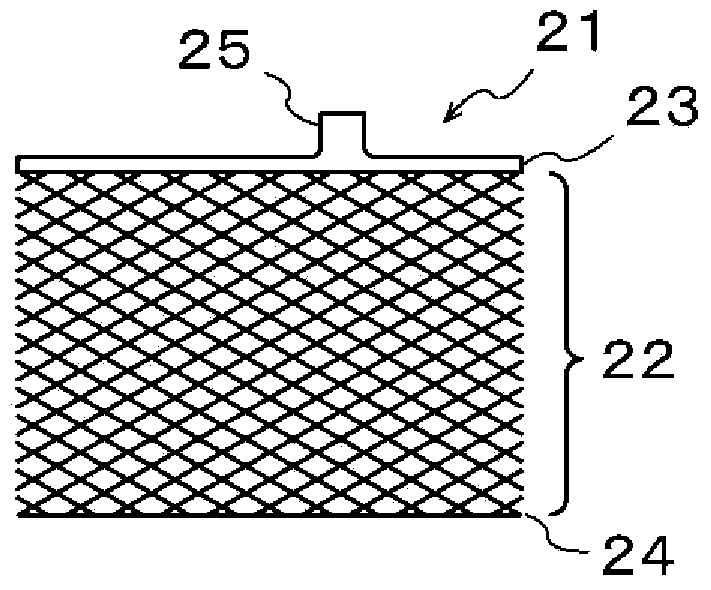

[0059] First, an unformed positive plate is prepared. Add water and knead in the mixture of lead oxide, lead red and chopped fiber (polyethylene terephthalate short fiber, the same below), and then add a small amount of dilute sulfuric acid while kneading to prepare the positive electrode With active substance paste. The active material paste is filled into a rolled sheet made of a lead alloy, such as figure 2 In the extended current collector 21 shown. The extended current collector 21 is composed of a grid portion 22 , an upper frame 23 , a lower frame 24 , and ear portions 25 . After filling the active material paste, it was aged for 24 hours in an atmosphere of 40° C. and a humidity of 95%, and then dried to obtain an unformed positive electrode plate.

[0060] Here, regarding the utilization rate related to the discharge reaction, positive electrode plates having various positive electrode active materials were produced as follows. That is, when the addition of dilut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com