Perforated foil used for current collector and its making method

A manufacturing method and fluid collector technology, applied in the field of energy storage devices, can solve the problems of large aperture, low production efficiency, expensive laser processing and manufacturing costs, etc., and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

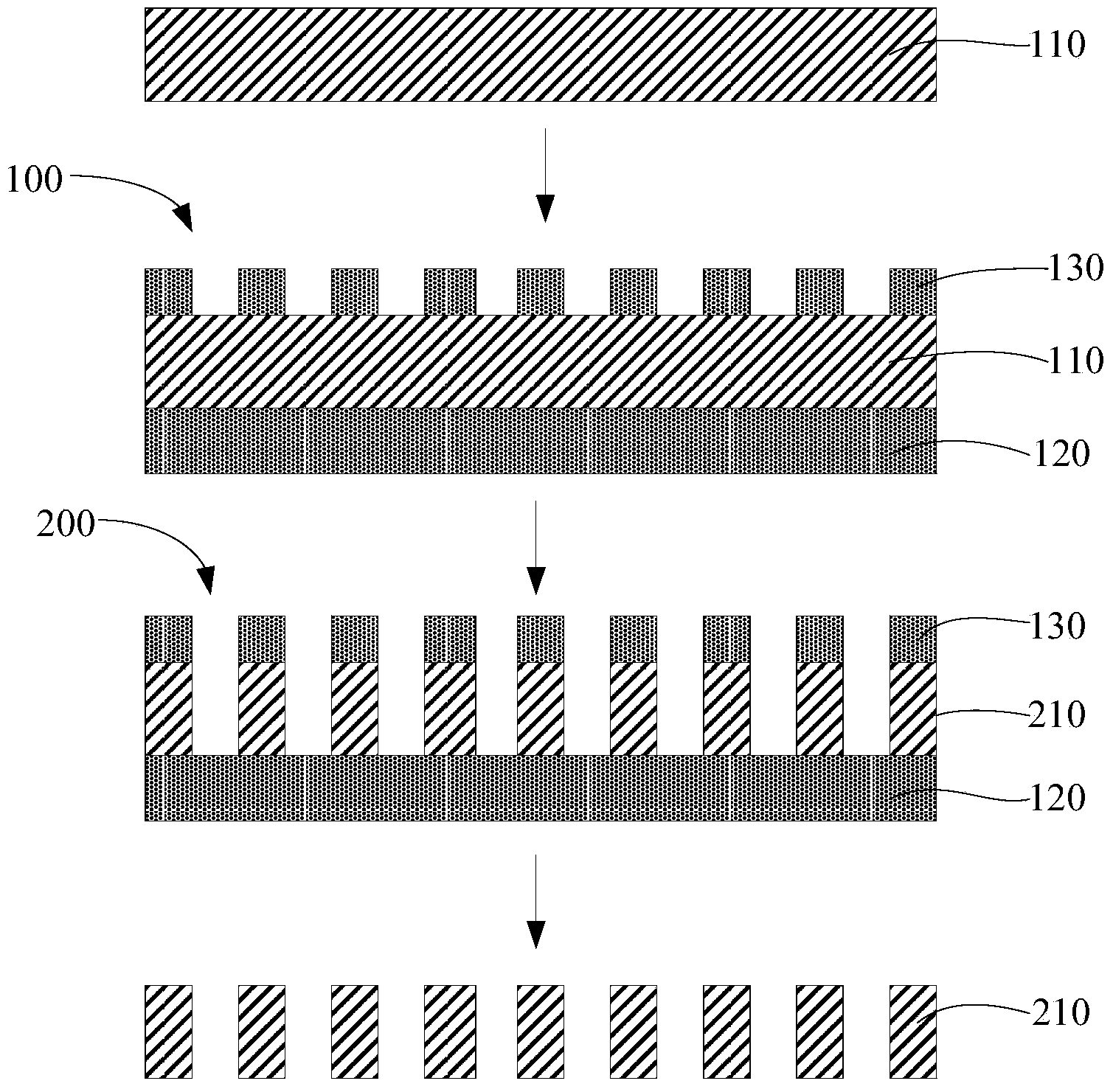

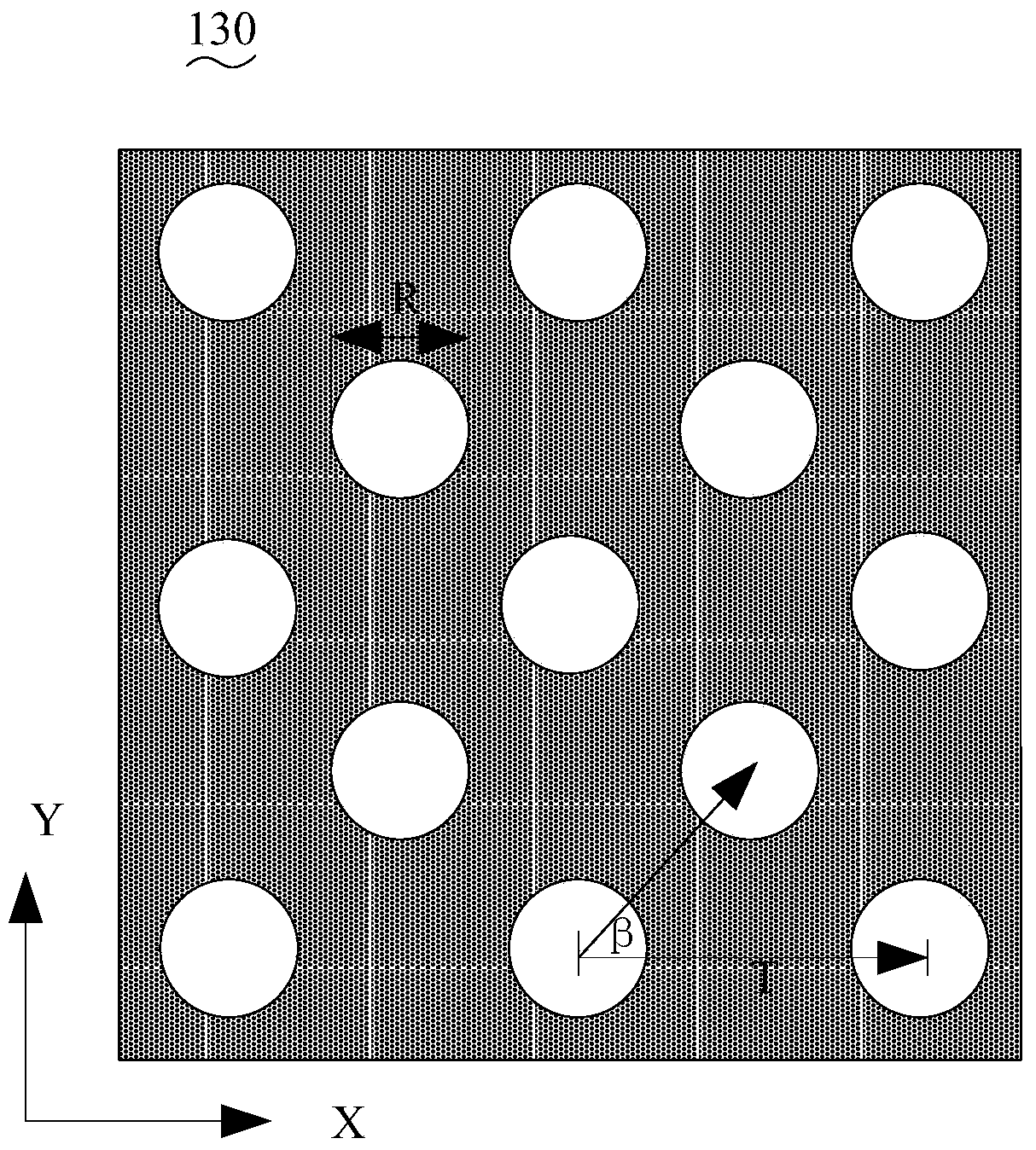

Method used

Image

Examples

Embodiment 1

[0044] Example 1 is a perforated copper foil for a current collector.

[0045] The specific manufacturing process of this embodiment is as follows:

[0046] Step 1, surface pretreatment; perform surface pretreatment on the copper foil for current collector according to the following procedure:

[0047] i) Ultrasonic solvent cleaning: unwind, immerse the copper foil in a trichlorethylene solution for ultrasonic cleaning, the ultrasonic power is 60W, the cleaning time is 20 minutes, and the solvent temperature is 24°C; after cleaning, immerse the copper foil in absolute ethanol for 20 minutes, The temperature is 24°C, and the ultrasonic power is 60W. The purpose of ultrasonic solvent cleaning is to remove the contamination on the copper foil surface, improve the adhesion between the mask and the copper foil surface and the uniformity of etching.

[0048] ii) Surface roughening: In order to further improve the adhesion between the copper foil and the mask, the surface of the co...

Embodiment 2

[0055] This embodiment is a perforated copper foil for current collector.

[0056] The specific manufacturing process of this embodiment is as follows:

[0057] Step 1, surface pretreatment; perform surface pretreatment on the copper foil for current collector according to the following procedure:

[0058] i) Ultrasonic solvent cleaning: unwind, immerse the copper foil in a trichlorethylene solution for ultrasonic cleaning, the ultrasonic power is 60W, the cleaning time is 20 minutes, and the solvent temperature is 24°C; after cleaning, immerse the copper foil in absolute ethanol for 20 minutes, The temperature is 24°C, and the ultrasonic power is 60W. The purpose of ultrasonic solvent cleaning is to remove the contamination on the copper foil surface, improve the adhesion between the mask and the copper foil surface and the uniformity of etching.

[0059] ii) Surface roughening: In order to further improve the adhesion between the copper foil and the mask, the surface of th...

Embodiment 3

[0066] This embodiment is a perforated aluminum foil for current collector.

[0067] The specific manufacturing process of this embodiment is as follows:

[0068] Step 1, surface pretreatment; perform surface pretreatment on the aluminum foil for the current collector according to the following procedures:

[0069] i) Ultrasonic solvent cleaning: unwind the roll, immerse the aluminum foil in trichlorethylene solution for ultrasonic cleaning, the ultrasonic power is 60W, the cleaning time is 20 minutes, and the solvent temperature is 24°C; after cleaning, immerse in absolute ethanol for ultrasonic cleaning for 20 minutes, the temperature 24°C, ultrasonic power is 60W. The purpose of ultrasonic solvent cleaning is to remove the contamination on the surface of the aluminum foil, improve the adhesion between the mask and the surface of the aluminum foil and the uniformity of etching.

[0070] ii) Surface roughening: In order to further improve the adhesion between the aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com