Evaporation source assembly

An evaporation source and component technology, which is applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of high AMOLED production cost, lower utilization rate of doping materials, uneven doping, etc. problems, to achieve the effects of reducing evaporation costs, promoting doping, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

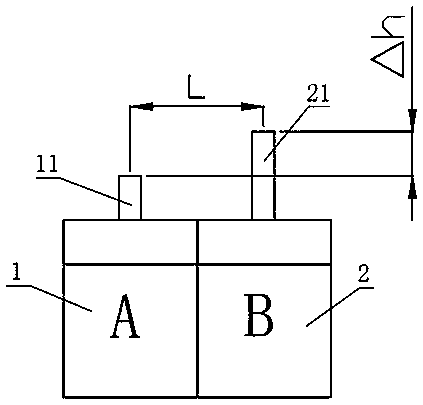

[0030] The applicant found that in the evaporation process, since it is necessary to achieve a certain doping ratio by controlling the evaporation rate of different materials, the evaporation rate of the host material is generally 2~10Å / s in the evaporation process, while the doping The evaporation rate of the material is 0.02~0.1 Å / s, which is very different.

[0031] Currently used evaporation sources, the structures of the evaporation sources used for the host material and the dopant material are almost the same, and when performing evaporation, the upper end surfaces of the nozzles are all at the same height. In the actual evaporation process, since the evaporation rate of the host material is much greater than that of the dopant material, the evaporation sublimation flow of the host material will impact the sublimation flow of the dopant material, which causes uneven doping and reduces the Utilization of dopant materials.

[0032] Thus, the present embodiment provides an...

Embodiment 2

[0042] This embodiment is an improved solution of Embodiment 1.

[0043] After the nozzle 21 of the B evaporation source is lengthened in the first embodiment, the dopant material is easily cooled and blocked at the nozzle. For improvement, a heater is provided at the B evaporation source nozzle 21 in this embodiment.

[0044] Such as Figure 4 As shown, the heater can be a resistive heater (such as a heating wire), and the resistive heater can be arranged on the outside or inside of the B evaporation source nozzle 21, and the heater can be specifically designed according to the shape and size of the nozzle.

[0045] The heater may also be a laser heater or the like. A laser heater may be provided outside the B evaporation source nozzle 21 .

Embodiment 3

[0047] In this embodiment, the evaporation rate at the nozzle 11 of the evaporation source A is greater than the evaporation rate at the nozzle 21 of the evaporation source B.

[0048] Such as Figure 5 As shown, the difference from the first and second embodiments is that in this embodiment, the A evaporation source 1 and the B evaporation source 2 have the same structure. That is, the height of the body itself and the length of the nozzle are the same. When arranging, the B evaporation source 2 is lifted up so that the height of the B evaporation source 2 is greater than the height of the A evaporation source 1. In this way, the upper end surface of the B evaporation source nozzle 21 can be higher than the A evaporation source nozzle 11. end face. The advantage of this is that the B evaporation source nozzle 21 does not need to be designed to be lengthened, and the B evaporation source nozzle 21 will not be easily blocked, and no additional heater is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com