Production method of graphene field-effect transistor

A technology of field effect transistor and manufacturing method, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inability to achieve large-scale, low-cost production, etc., and achieve the effect of solving extreme chirality dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The manufacture method of the graphene field effect tube provided by the present embodiment comprises:

[0043] A semiconductor substrate is provided, and a silicon dioxide layer is formed on the surface of the semiconductor substrate;

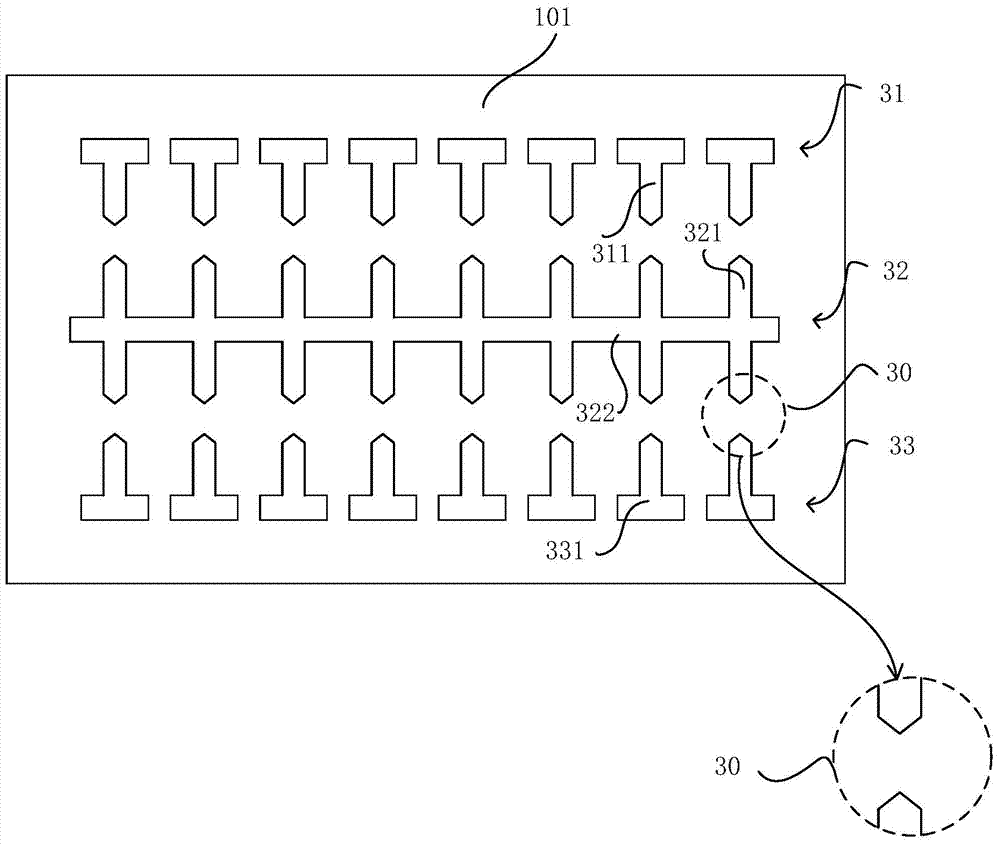

[0044] A floating potential AC dielectrophoretic structure is formed on the semiconductor substrate, and the floating potential AC dielectrophoretic structure includes:

[0045] The first electrode part, the second electrode part and the third electrode part, wherein the first electrode part includes at least a first sub-electrode, the second electrode part includes at least a second sub-electrode and a sub-electrode connection line, and the sub-electrode connection line Connecting through all the second sub-electrodes, the third electrode part includes at least a third sub-electrode, the first sub-electrode and the second sub-electrode, and the top ends of the second sub-electrode and the third sub-electrode are respectively facing eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com