High dissolved oxygen bioreactor for high-density culture of genetically engineered bacteria and culture control method

A high-density culture and genetically engineered bacteria technology, applied in the field of high dissolved oxygen bioreactors, can solve the problems of unfavorable shear-sensitive microbial growth, unfavorable microbial growth, weak macro-mixing strength, etc. Good liquid dispersion performance and the effect of overcoming the lack of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

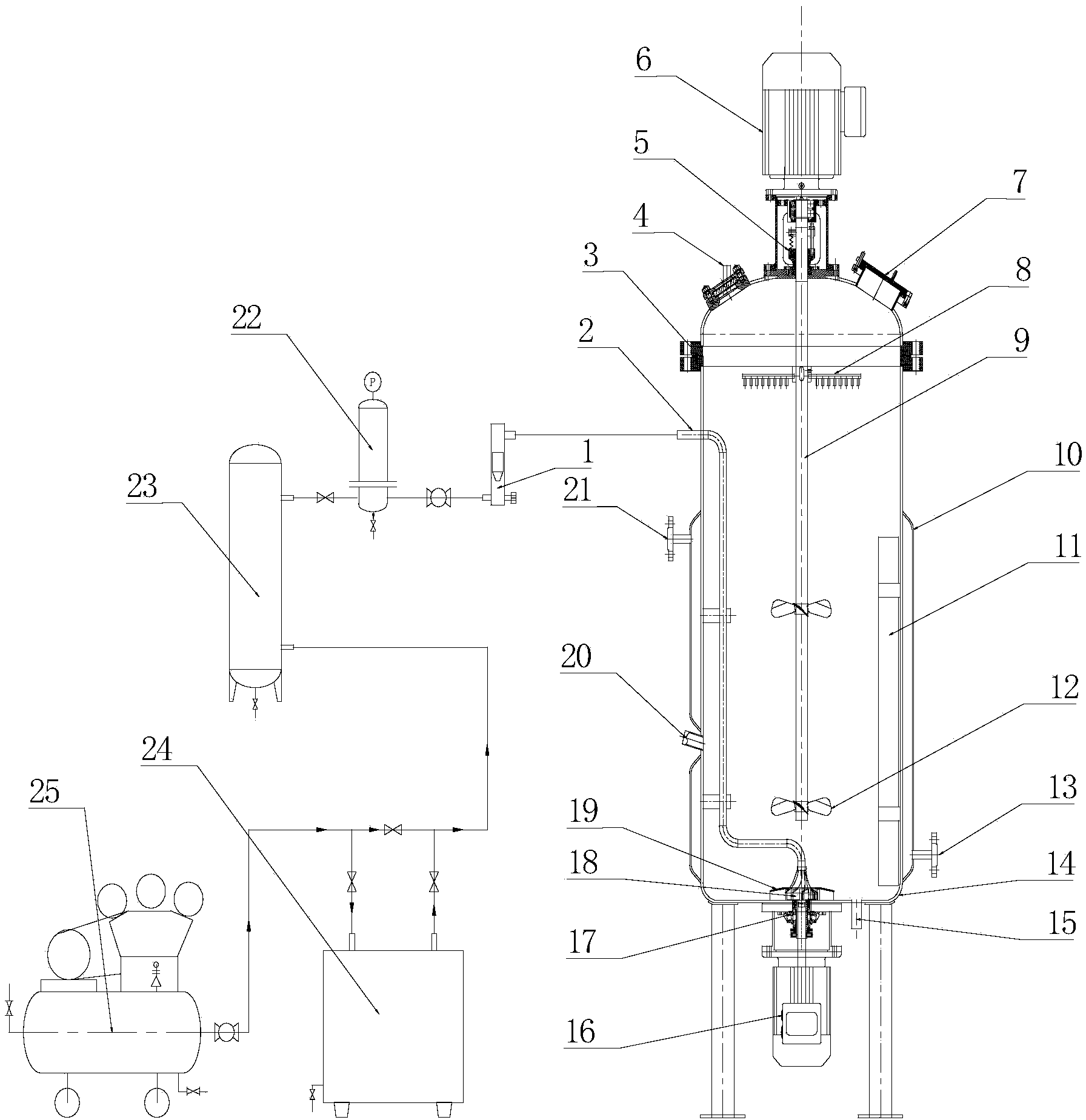

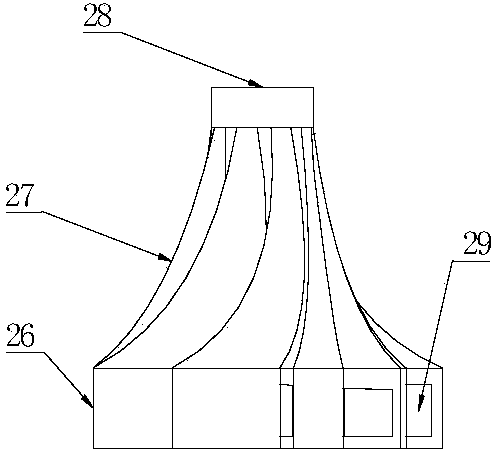

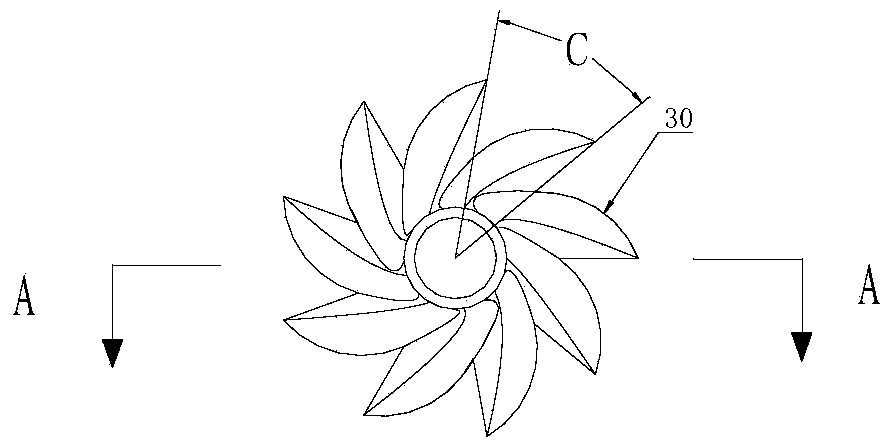

[0054] Such as Figure 1 to Figure 6 As shown, the high-dissolved oxygen bioreactor for the high-density cultivation of genetically engineered bacteria of the present embodiment comprises a tank body with feeding holes 4 in the upper part and a discharge port 15 in the lower part. The output shaft of the drive motor 6 is connected to the stirring paddle extending into the tank; the rotor drive motor 16 is arranged outside the bottom of the tank, and the output shaft of the rotor drive motor 16 is connected to the gas-liquid dispersion rotor 18 inside the tank to achieve gas-liquid dispersion. The rotor 18 has a ventilated inner chamber with an air inlet on the top and an air outlet on the bottom, and the air inlet is connected to a pressurized air source through a pipeline; The diversion groove of the water inlet and the water outlet is established; the gas-liquid dispersion stator 19 is located in the circumferential direction of the gas-liquid dispersion rotor 18, and the ga...

Embodiment example 1

[0096] The size of the reactor is: the volume of the tank is 5m 3 , the height-to-diameter ratio of the tank is 2.2:1, the diameter of the gas-liquid dispersion rotor is 215mm, the gas-liquid dispersion stator is designed with 16 diversion grooves, the outer diameter is 405mm, and the width of the four baffles is 140mm. There are two layers of stirring paddles with a diameter of 500 mm.

[0097] In this implementation case, under the condition of 2.8 tons of liquid, the critical air flow rate of the gas-liquid dispersion rotor at a speed of 2100r / min, the critical speed of the gas-liquid dispersion rotor at this air flow rate, and the maximum stirring speed were measured.

[0098] The measured critical ventilation volume is 134.4m 3 / h, according to 85% of the critical ventilation rate is 114.2m 3 / h air intake, the measured critical speed of the gas-liquid dispersion rotor is 1950r / min. The speed of the gas-liquid dispersion rotor is set to 120% of the critical speed, that ...

Embodiment example 2

[0103] The size of the reactor is: the volume of the tank is 5m 3 , the height-to-diameter ratio of the tank is 2.2:1, the diameter of the gas-liquid dispersion rotor is 215mm, the gas-liquid dispersion stator is designed with 16 diversion grooves, the outer diameter is 405mm, and the width of the four baffles is 140mm. There are two layers of stirring paddles with a diameter of 500 mm.

[0104] In this implementation case, under the condition of 2.8 tons of liquid, the critical air flow rate of the gas-liquid dispersion rotor at a speed of 2100r / min, the critical speed of the gas-liquid dispersion rotor at this air flow rate, and the maximum stirring speed were measured.

[0105] The measured critical ventilation volume is 134.4m 3 / h, according to 70% of the critical ventilation rate is 94m 3 / h air intake, the measured critical speed of the gas-liquid dispersion rotor is 1780r / min. The speed of the gas-liquid dispersion rotor is set to 120% of the critical speed, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com