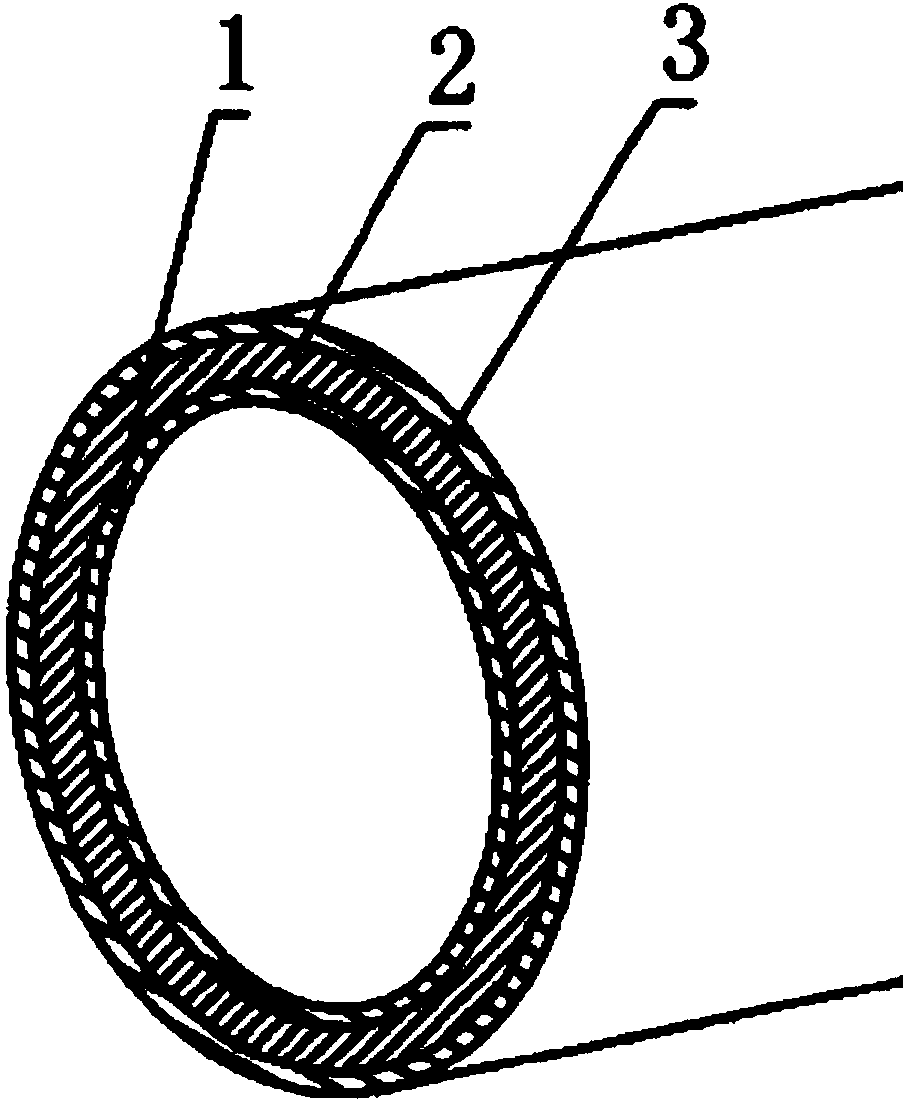

Weather-resistant colored composite PVC (Polyvinyl Chloride) pipe

A PVC pipe, color technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of unable to meet the diversified needs of users, expensive titanium dioxide, increase production costs, etc. Small friction coefficient, low cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

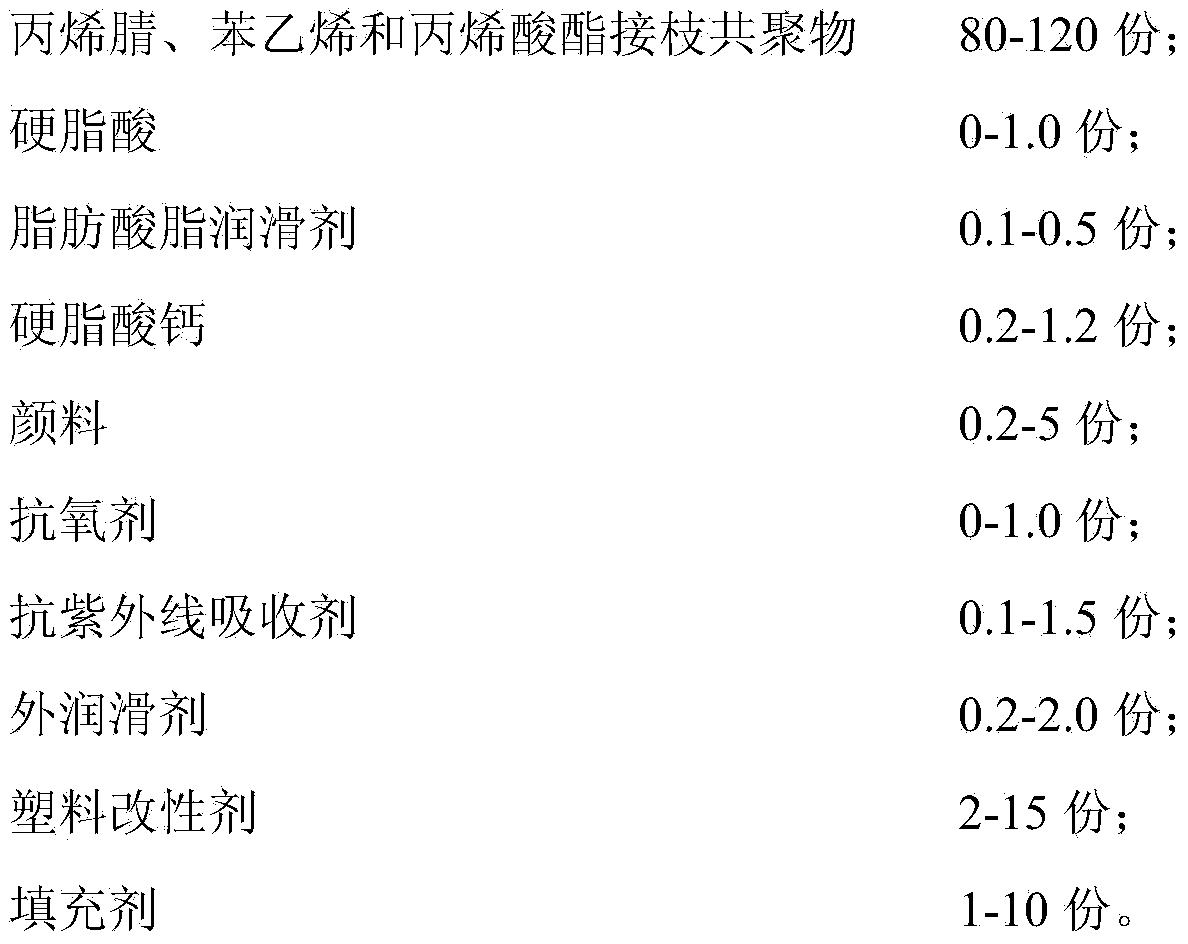

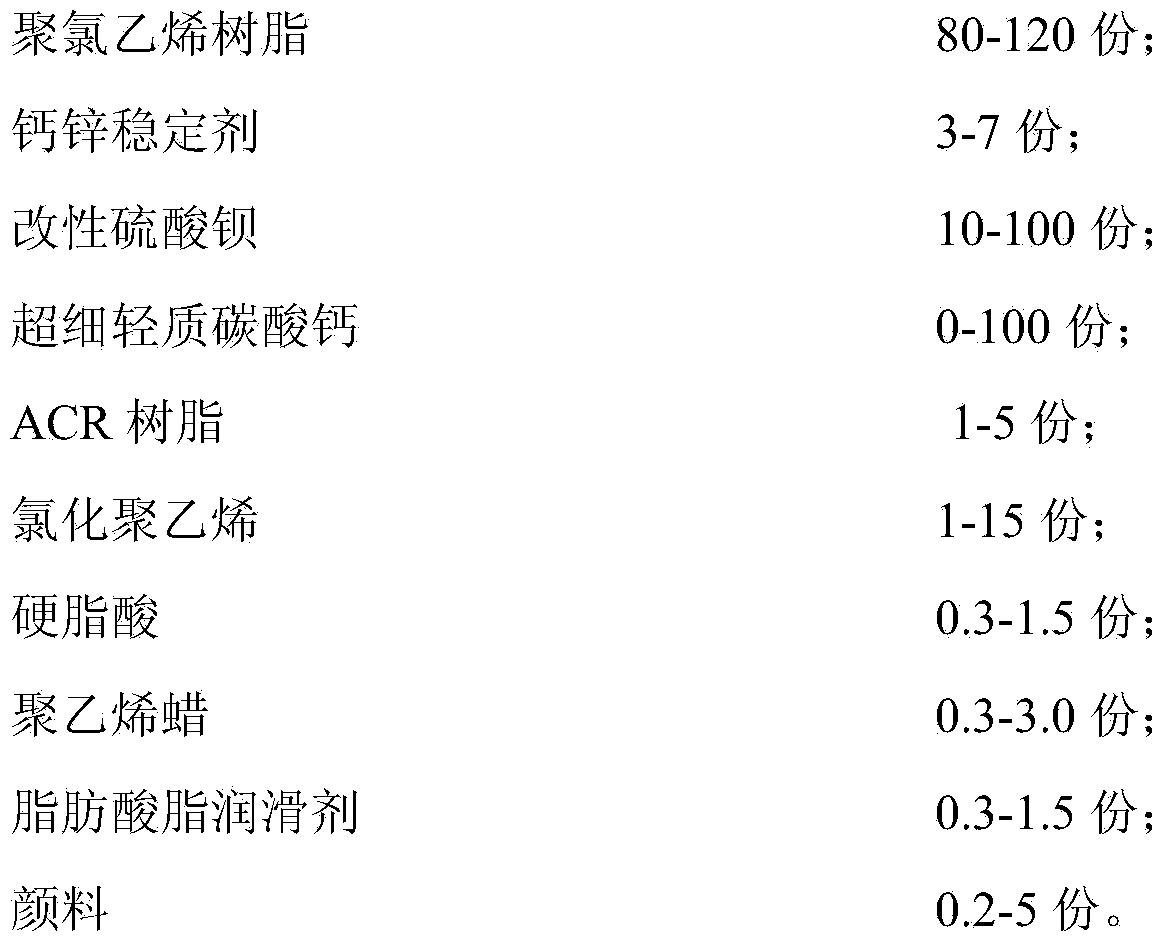

[0027] The method for preparing a weather-resistant colored composite PVC pipe in this embodiment includes the following steps: 1. Preparation of modified barium sulfate: first select 100 parts of barium sulfate powder with a particle size ≤ 3.0 μm, and then put the selected powder in a special mixer Pre-mix to 80-85°C, then add 1 part of coupling agent (Titanate TC-130), 1 part of stearic acid (HST) to the pre-mixed powder and high-mix to 110-120°C, and finally cold mix When the temperature is lower than 50°C, discharge the material to obtain modified barium sulfate; 2. Mix and granulate the PVC core layer and the inner and outer layers of ASA: according to Table 1 (modified barium sulfate in Table 1 is prepared by step 1) and Table 2 respectively Select the raw materials of the PVC core layer and the inner and outer layers of ASA, and then mix and granulate the selected raw materials separately; 3. Co-extrusion compound: the main machine and co-extrusion auxiliary machine co-...

Embodiment 2

[0034] The method for preparing a weather-resistant colored composite PVC pipe in this embodiment includes the following steps: 1. Preparation of modified barium sulfate: first select 100 parts of barium sulfate powder with a particle size ≤ 3.0 μm, and then put the selected powder in a special mixer Pre-mix to 80-85°C, then add 1 part of coupling agent (Titanate TC-130), 1 part of stearic acid (HST) to the pre-mixed powder and high-mix to 110-120°C, and finally cold mix When the temperature is lower than 50°C, discharge the material to obtain modified barium sulfate; 2. Mix and granulate the PVC core layer and the inner and outer layers of ASA: according to Table 3 (modified barium sulfate in Table 3 is prepared by step 1) and Table 4 respectively Select the raw materials of the PVC core layer and the inner and outer layers of ASA, and then mix and granulate the selected raw materials separately; 3. Co-extrusion compound: the main machine and co-extrusion auxiliary machine co-...

Embodiment 3

[0041] The method for preparing a weather-resistant colored composite PVC pipe in this embodiment includes the following steps: 1. Preparation of modified barium sulfate: first select 100 parts of barium sulfate powder with a particle size ≤ 3.0 μm, and then put the selected powder in a special mixer Pre-mix to 80-85°C, then add 1 part of coupling agent (Titanate TC-130), 1 part of stearic acid (HST) to the pre-mixed powder and high-mix to 110-120°C, and finally cold mix When the temperature is lower than 50°C, discharge the material to obtain modified barium sulfate; 2. Mix and granulate the PVC core layer and the inner and outer layers of ASA: according to Table 5 (modified barium sulfate in Table 5 is prepared by step 1) and Table 6 respectively Select the raw materials of the PVC core layer and the inner and outer layers of ASA, and then mix and granulate the selected raw materials separately; 3. Co-extrusion and compounding: the main machine and co-extrusion auxiliary mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com