A kind of water-resistant flame-retardant PVC cable sheathing material and preparation method thereof

A cable sheathing material and raw material technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of electrical insulation properties that have not been successfully solved, and achieve the effects of no decline in product performance, broad application prospects, and excellent flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

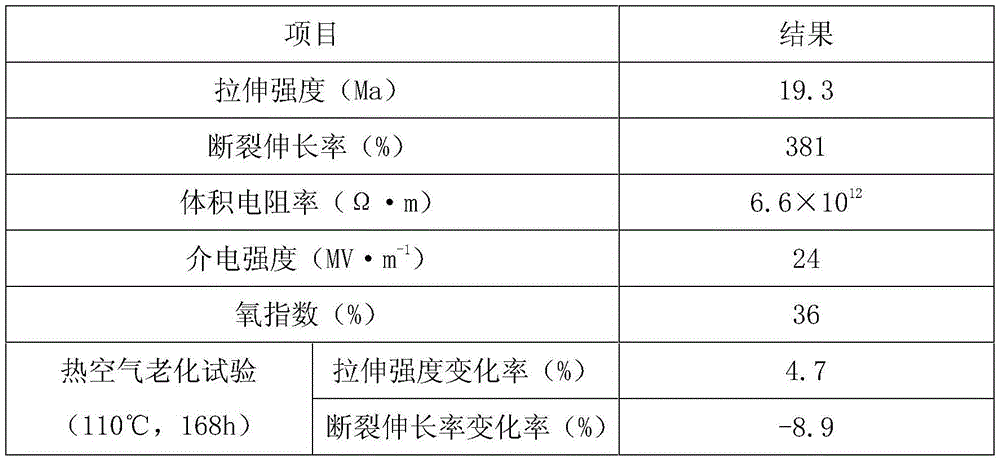

[0010] A water-resistant and flame-retardant PVC cable sheathing material, made of the following raw materials (kg): SG-4 type polyvinyl chloride resin 80, polyetheretherketone 20, ABS10, diisodecyl phthalate 10, Dibutyl maleate 8, fumed white carbon black 20, calcium zinc composite stabilizer 1.5, barium stearate 2, tris(xylene) phosphate 10, palm wax 4, magnesium hydroxide 12, decabromodi Phenyl ethyl 8, zinc borate 5, pumice powder 8, nano barium titanate 10, composite filler 4;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 4:4:2, then add 2% coal powder and 1% activated carbon by weight of bentonite, and mix them uniformly at 550 ° C. Calcined for 4 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water to make a slurry with a concentration of 45%, added hydrochloric acid solution with a concentration of 12% to adjust the pH of the slurry to 5.5, heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com