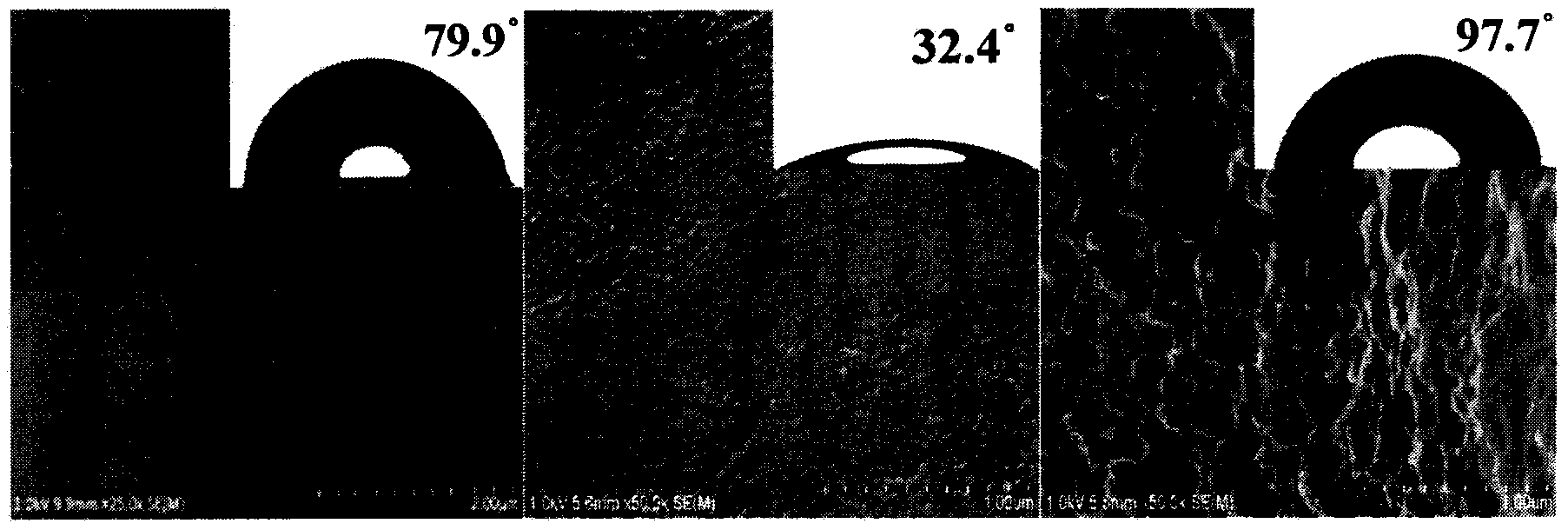

Photosensitive degradable comb-like copolymer film with controllable surface appearance and performance

A comb-like copolymer and photosensitivity technology, which can be used in medical preparations with non-active ingredients, wave energy or particle radiation treatment materials, medical preparations containing active ingredients, etc., can solve the problem of waste of drugs and resources, low sensitivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The acid chloride reaction of embodiment 1, CA

[0021] Accurately weigh 14.8170g (100mmol) of CA and add it to a 100ml round bottom flask, add 40ml (550mmol) of thionyl chloride (SOCl 2 ), 20ml dichloromethane (CH 2 Cl 2 ) and five drops of DMF, where CH 2 Cl 2 and DMF as solvent and catalyst respectively, install a reflux system, and heat to reflux for 7 hours under constant temperature oil bath magnetic stirring at 60°C. After the reaction, distill off unreacted SOCl under reduced pressure at room temperature 2 and a solvent, and vacuum-dried at 50° C. for 24 h to obtain the light yellow target product cinnamoyl chloride (CC), with a yield of more than 85%.

Embodiment 2

[0022] Embodiment 2, photosensitive macromonomer (FM n C) Synthesis

[0023] 25 mmol of ε-caprolactone-modified methyl methacrylate FM n (n=1~3) series monomers were dissolved in 10mL of tetrahydrofuran (THF) solvent, and then 2~3mL of triethylamine was added, and 30mmol of CC in THF solution was added dropwise in an ice-water mixture bath, and at room temperature After reacting for 12 hours, the obtained product was filtered, and the filtrate was diluted with anhydrous ether, then washed with 5wt% hydrochloric acid, then 5wt% sodium bicarbonate solution, and finally deionized water twice, and vacuum-dried at room temperature to obtain light yellow target product FM n c.

Embodiment 3

[0024] Embodiment 3, photosensitive comb copolymer PFM n Synthesis of S

[0025] Taking the molar ratio of the three monomers as 1:1:25 as an example, weigh 0.8706g of FMC monomer, 9.3230g of MAPEG macromer and 6.0679g of St monomer into a 100ml round bottom flask, then add 50ml of solvent THF, 0.1550g of initiator AIBN accounting for 1.5% of the total molar ratio of monomers, filled with N 2 After replacement and deoxidation, seal and react in a constant temperature oscillating oil bath at 65°C and 120r / min for 12h to obtain a comb copolymer P(FMC-co-MAPEG-co-St) (hereinafter referred to as PFM n S indicates). The product was precipitated with anhydrous ether, dissolved and precipitated repeatedly 3 times, unreacted monomers were removed, and dried in a vacuum oven at 30°C to obtain a white powder sample. Change the molar ratio of the three monomers, and prepare a series of comb copolymers PFM in the same way n S.

[0026] The resulting copolymer is:

[0027]

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com