Lithium-aluminum-silicon-based glass material capable of photolithography, preparation method and application thereof

A glass material, lithium aluminum silicon technology, applied in the direction of glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as difficult to meet the application of electronic devices, unable to meet the use requirements, glass strength decline, etc., to weaken the overall polarization rate, reduce the number of non-bridging oxygen, and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

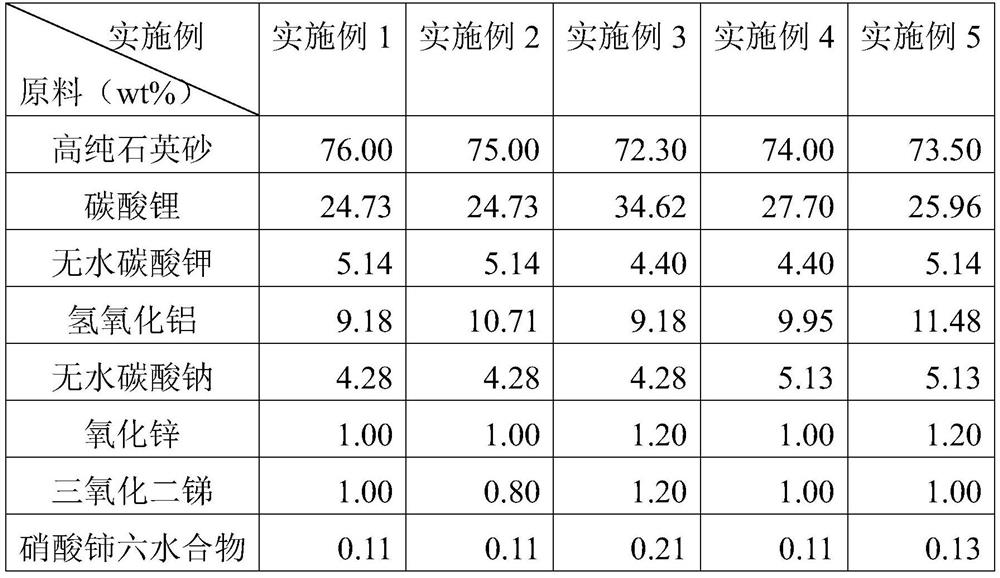

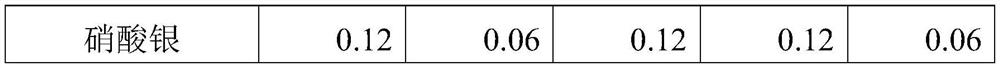

[0036] The preparation method of the photolithographic lithium-aluminum-silicon glass material of the above-mentioned embodiment 1-embodiment 5 comprises the following steps:

[0037] 1) Mix high-purity quartz sand, lithium carbonate, anhydrous potassium carbonate, aluminum hydroxide, anhydrous sodium carbonate, zinc oxide, antimony trioxide, cerium nitrate hexahydrate, and silver nitrate according to the formula in Table 1, respectively , to get the batch material;

[0038] 2) Put the batch material obtained in step 1) into the mixer to fully grind and mix, and sieve through 40 mesh; put it in a high-temperature melting furnace, melt it at 1520°C for 1 hour, and stir it at a speed of 15r / min for 1 hour hour, then stirred at a speed of 30r / min for 2 hours, then stirred at a speed of 15r / min for 1 hour (to make clarification and homogenization better), so that the batch material was completely melted into a liquid state for clarification and homogenization;

[0039] 3) After t...

Embodiment 3

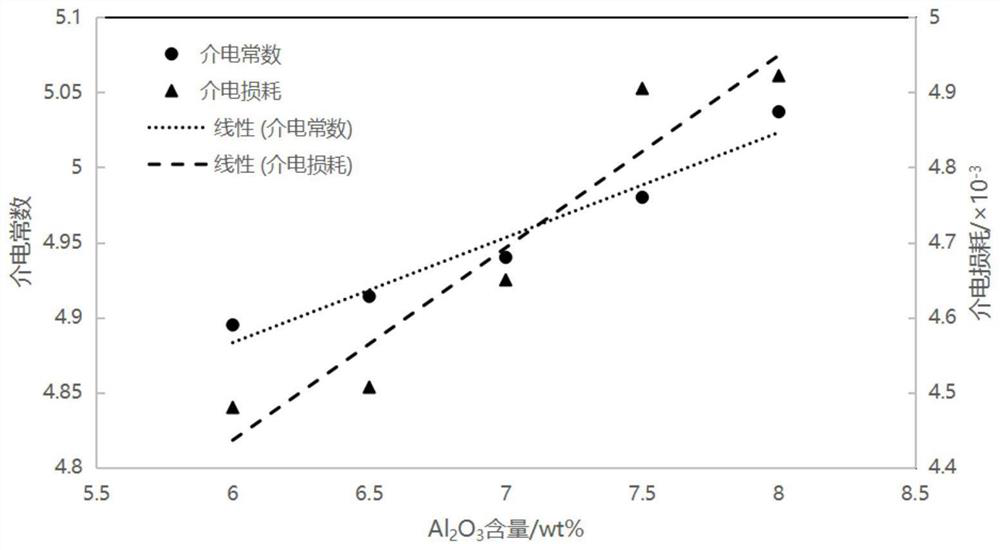

[0045] The Al content of embodiment 3 is identical with embodiment 1, but because Li + The higher the content, the stronger the ion polarization in the glass, the higher the dielectric constant, the weaker the mixed alkali effect, and the higher the dielectric loss.

Embodiment 6

[0047] This embodiment provides a method for preparing a photolithographic lithium-aluminum-silicon-based glass material. The difference between this preparation method and the preparation method in the above-mentioned embodiment 1 is that the melting temperature in step 2) of this embodiment is 1500° C. . The specific components of the prepared lithium-aluminum-silicon glass material are the same as those in Example 1.

[0048] Photolithographic glass can also be obtained by lowering the melting temperature, but there are occasional unmelted materials in the formed glass block. It has been verified that the glass obtained by this process still has photosensitive properties, but in the subsequent processing process, it must be avoided. Impurities such as unmelted material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com