Process for producing hydrogen by use of burning carbon black tail gas

A process and tail gas technology, which is applied in the process field of using carbon black tail gas to produce hydrogen, can solve problems such as environmental pollution, and achieve the effects of simple process flow, energy saving and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

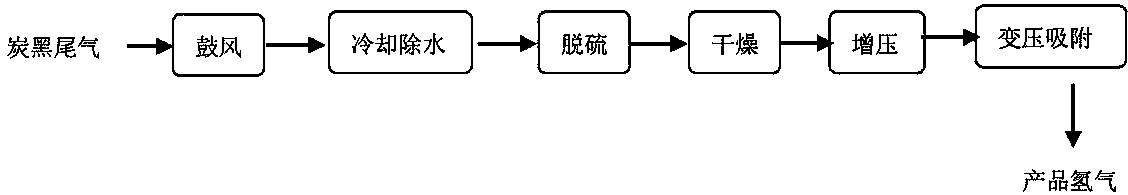

Embodiment 1

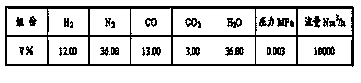

[0039] The carbon black tail gas from the carbon black plant at about 80°C (see Table 1 for the composition) enters the water-cooled shock tube after blowing to 50kpa, the circulating cooling water contacts the hot carbon black tail gas, the temperature drops to normal temperature, and enters the gas-water separator for separation The liquid water enters the desulfurization system for desulfurization, and the desulfurization method adopts the NHD (polyethylene glycol dimethyl ether) method.

[0040] The gas enters from the lower part of the absorption tower and passes through the absorption tower from bottom to top; the regenerated NHD solution (lean liquid) enters from the upper part of the absorption tower and passes through the absorption tower from top to bottom, and the counter-flowing NHD and mixed gas are fully absorbed in the absorption tower Contact, H in gas 2 S, SO 2 , SO 3 and CO 2 absorbed.

[0041] The absorbent that has absorbed the acid gas is called rich l...

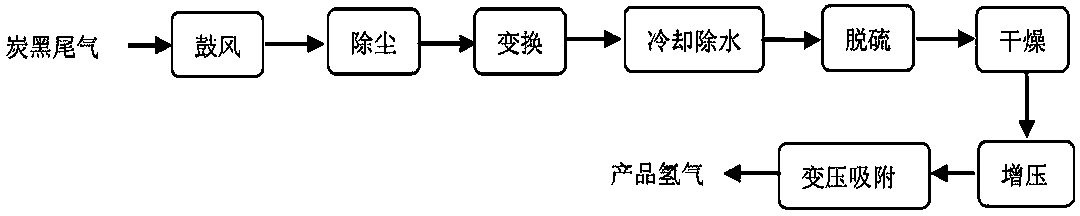

Embodiment 2

[0051] The carbon black tail gas from the carbon black plant at about 140°C (see Table 1 for components) is pressurized by the blower at 50kpa, then enters the bag filter for dust removal, enters the shift reaction preheater and heats it to 200°C, then enters the shift reactor. Under this condition, CO in the gas undergoes a shift reaction with water vapor (see equation 1). At the beginning of the reaction, use the high-temperature gas from the carbon black plant or an electric heater to heat the raw material intake. After the reaction starts, use the high-temperature mixed gas from the shift reactor to preheat the raw material intake. The main component of the mixed gas from the shift preheater is CO , CO 2 、H 2 , N 2 And water vapor, the hot gas is used to heat the desulfurized and decarbonized rich liquid to further recover heat. The cooled mixed gas enters the cooler to cool to normal temperature, then enters the gas-water separator to separate liquid water, and then en...

Embodiment 3

[0061] The carbon black tail gas from the carbon black plant at about 120°C (see Table 5 for components) is pressurized by the blower to 70kpa, then enters the bag filter for dust removal, enters the shift reaction preheater to be heated to 250°C, and then enters the shift reactor. Under the action of the catalyst, the CO in the gas and water vapor undergo a transformation reaction, and the transformed hot gas enters the transformation preheater to preheat the raw material mixture gas, and the main component of the mixture gas exiting the transformation reaction system is CO 2 、H 2 , N 2 And water vapor, the mixed gas enters the cooler to cool to normal temperature, then enters the gas-water separator to separate liquid water, and enters the desulfurization system. The desulfurization method adopts the PDS method, and the operation mode is the same as that of Example 1. After desulfurization, the total S content is lower than 1mg / m 3 , CO 2 Content below 100 mg / m 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com