Ginkgo leaf capsule and preparation method thereof

A technology of ginkgo leaf capsules and ginkgo leaves, applied in the direction of capsule delivery, medical raw materials derived from ginkgo biloba, and pharmaceutical formulations, etc., can solve the problems of uneven particle color, easy moisture absorption of capsule particles, and low clinical curative effect, so as to achieve non-staining Bacteria, solubility and chemical and physical stability are improved, and the effect of not easily polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

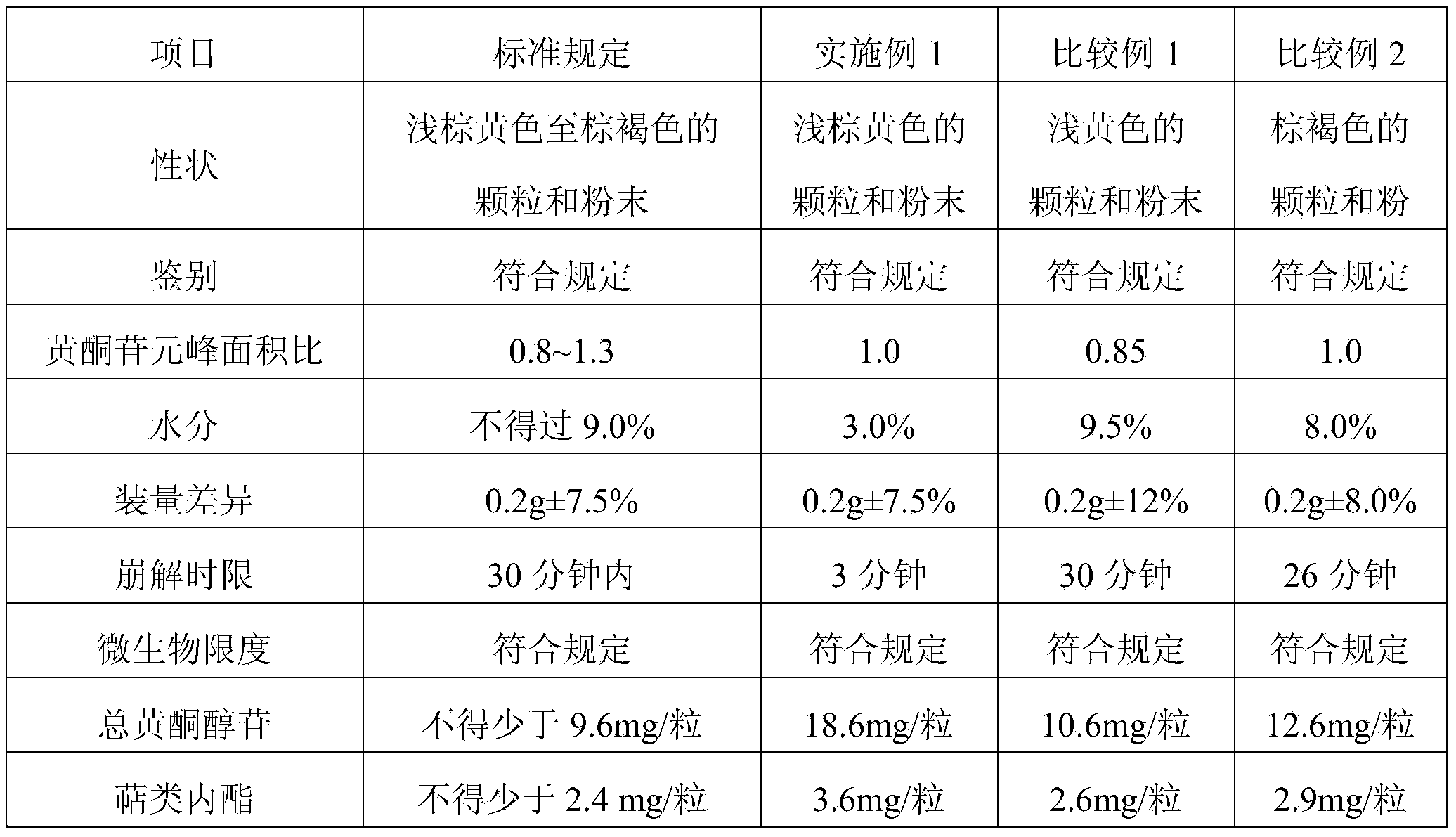

Embodiment 1

[0039] A kind of ginkgo leaf capsule raw material formula of the present invention:

[0040] Ginkgo biloba extract 40g, β-cyclodextrin 150g, talcum powder 9g, magnesium stearate 1.0g.

[0041] The preparation method is as follows:

[0042] 1. Ingredients: Take 95% ethanol and prepare 25% ethanol, add 150g of β-cyclodextrin into it and stir well, so that the weight ratio of β-cyclodextrin and ethanol reaches 1:10, and obtain granulation spray grout.

[0043]2. Granulation: Put 40g of ginkgo leaf extract and 9g of talcum powder together in the hopper of the boiling granulation dryer, turn it on and mix well, then send the β-cyclodextrin ethanol solution spray liquid obtained in step 1) into the boiling granulation dryer. The spraying device of the granulation dryer starts spraying and granulating, so that the boiling granulation and drying can be granulated in one step, and the particle rate can reach more than 80%.

[0044] Technical parameter control: spray speed 32±2v / min,...

Embodiment 2

[0050] A kind of ginkgo leaf capsule raw material formula of the present invention:

[0051] Ginkgo biloba extract 30g, β-cyclodextrin 180g, talcum powder 7g, magnesium stearate 1.5g.

[0052] The preparation method is as follows:

[0053] 1. Ingredients: take 95% ethanol and prepare 25% ethanol, add 180g of β-cyclodextrin into it and stir well, so that the weight ratio of β-cyclodextrin and ethanol reaches 3:20, and obtain granulation spray grout.

[0054] 2. Granulation: Put 30g of ginkgo leaf extract and 7g of talcum powder together in the hopper of the fluidized granulation dryer, turn it on and mix well, then send the β-cyclodextrin ethanol solution spray liquid obtained in step 1) into the The spraying device of the fluidized granulation dryer starts spraying granulation, so that the fluidized granulation drying can be granulated in one step, and the particle rate can reach 70%.

[0055] Technical parameter control: spray speed 40v / min, spray pressure 2.5×0.1Mpa; top ...

Embodiment 3

[0061] A kind of ginkgo leaf capsule raw material formula of the present invention:

[0062] Ginkgo biloba extract 50g, β-cyclodextrin 120g, talcum powder 12g, magnesium stearate 0.5g.

[0063] The preparation method is as follows:

[0064] 1. Ingredients: take 95% ethanol and prepare 25% ethanol, add 120g of β-cyclodextrin into it and stir well, so that the weight ratio of β-cyclodextrin and ethanol reaches 1:20, and obtain granulation spray grout.

[0065] 2. Granulation: put 50g of ginkgo leaf extract and 12g of talcum powder together in the hopper of the fluidized granulation dryer, turn it on and mix well, then send the β-cyclodextrin ethanol solution spray liquid obtained in step 1) into the The spraying device of the fluidized granulation dryer starts spraying and granulating. In this way, boiling granulation and drying can be granulated in one step, and the particle rate can reach 65%.

[0066] Technical parameter control: spray speed 30v / min, spray pressure 2.5×0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com