Preparation method of high-activity buckwheat leaf flavonoids

A technology of buckwheat leaf flavonoids and high activity, which is applied in the field of preparation of high-activity buckwheat leaf flavonoids, can solve the problems of low development and utilization of buckwheat leaves, reduced safety, expensive enzyme preparations, etc., and achieves improved absorption and bioavailability and low cost , good fat-soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of buckwheat leaf flavonoids crude extract: wash and dry the buckwheat leaves harvested in the field, grind them, and pass through a 60-mesh sieve to obtain buckwheat leaf powder; weigh 40 g of buckwheat leaf powder, add 1600 mL of 85% edible ethanol (solid-liquid ratio 1:40), mix well, put it in a 70°C water bath, stir and extract for 4 hours, take it out, filter while hot to obtain the filtrate, wash the precipitate once with 2 times of 85% edible ethanol, combine the filtrate; concentrate with a rotary evaporator When the filtrate reached 300mL, a large amount of precipitation was precipitated; the concentrated solution was centrifuged, and the precipitate was dried and crushed at 60°C to obtain 5.33g of buckwheat leaf flavonoid crude extract, with a total flavonoid content of ≥73.5%.

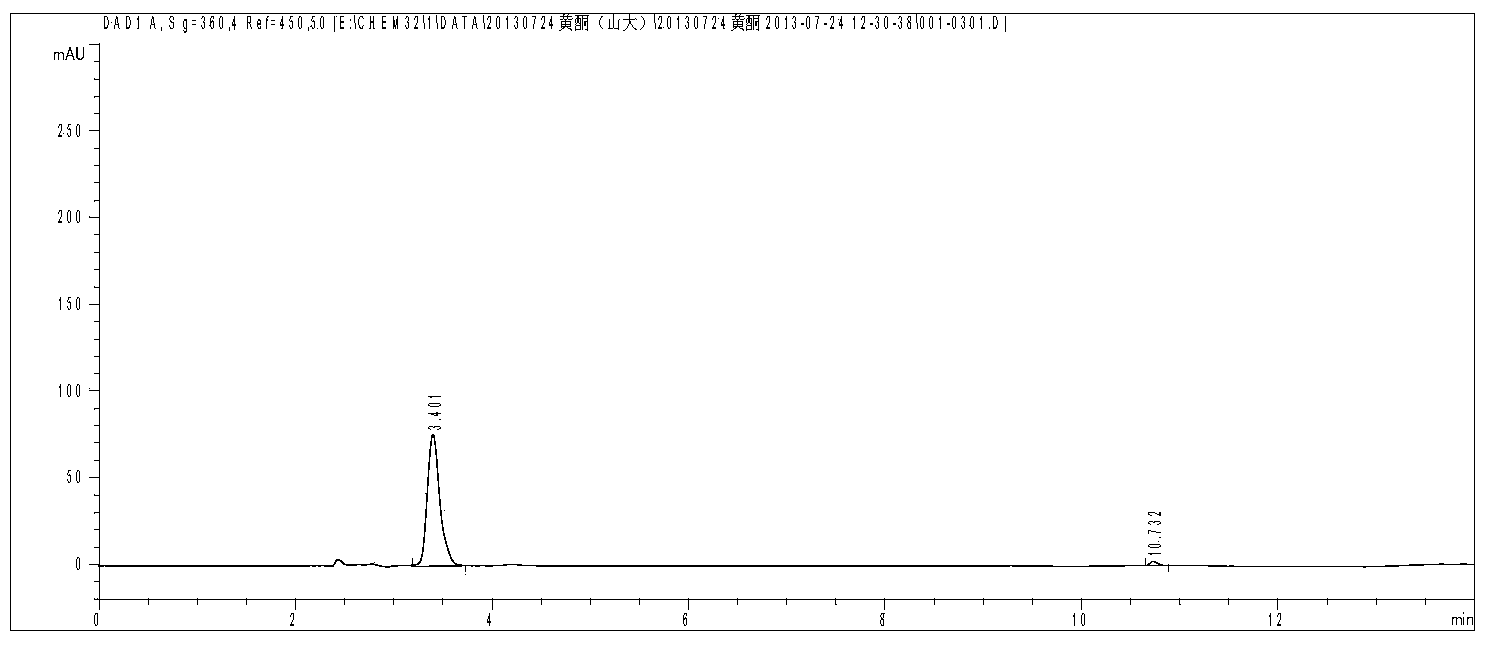

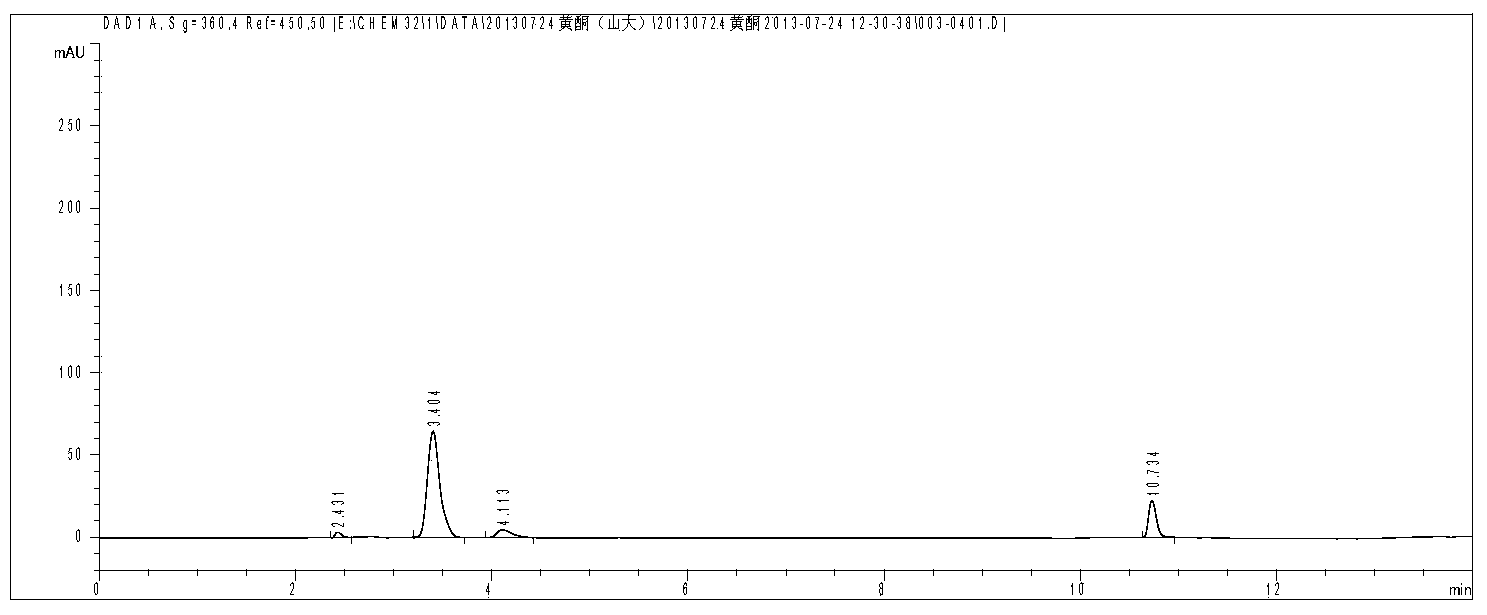

[0023] Determination of flavonoid components and content by high performance liquid chromatography: Instrument: 1100 series high performance liquid chromatography from ...

Embodiment 2

[0032]Preparation of highly active buckwheat leaf flavonoids: Wash and dry the buckwheat leaves harvested in the field, grind them, and pass through a 60-mesh sieve to obtain buckwheat leaf powder; weigh 40g of buckwheat leaf powder, add 85% edible ethanol 2000mL (solid-liquid ratio 1 :50), mix well, put into 70 DEG C of water baths and stir and extract for 4h, after taking it out, suction and filter while hot to obtain the filtrate, wash the precipitate once with 2 times of 85% ethanol, combine the filtrate; concentrate the filtrate to 200mL, put it into a high-pressure reactor, and hydrolyze it at 0.7MPa for 20min. After the reactor cools down, pour the hydrolyzate into a centrifuge cup, collect the precipitate by centrifugation at 6000g, wash the precipitate with distilled water 4 times, and dry the obtained precipitate at 60°C to obtain Buckwheat leaf flavonoid products with higher physiological activity, the total flavonoid content of the product is ≥88.8%.

[0033] The a...

Embodiment 3

[0036] Preparation of highly active buckwheat leaf flavonoids: Wash and dry the buckwheat leaves harvested in the field, grind them, and pass through a 60-mesh sieve to obtain buckwheat leaf powder; weigh 40g of buckwheat leaf powder, add 1600mL of 85% edible ethanol (solid-liquid ratio 1 :40), mix well, put it in a 70°C water bath, stir and extract for 4 hours, take it out, and filter while hot to obtain the filtrate, wash the precipitate once with 2 times of 85% edible ethanol, and combine the filtrate; use a rotary evaporator to concentrate the filtrate to 160mL, put it into a high-pressure reactor, and hydrolyze it at 0.7MPa for 60 minutes. After the reactor cools down, pour the hydrolyzate into a centrifuge cup, collect the precipitate by centrifugation at 6000g, wash the precipitate with distilled water 4 times, and dry the precipitate at 60°C. Obtain a buckwheat leaf flavonoid product with higher physiological activity, and the total flavonoid content of the product is ≥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com