Baseless light inspection machine for freeze-dried vials

A technology for vials and light inspection machines, which is applied in the direction of optical testing for flaws/defects, etc. It can solve problems such as difficult to guarantee processing accuracy, difficult to clean, and high requirements for inspection processes, so as to improve stability and inspection accuracy, and facilitate inspection and maintenance. , Guarantee the effect of the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

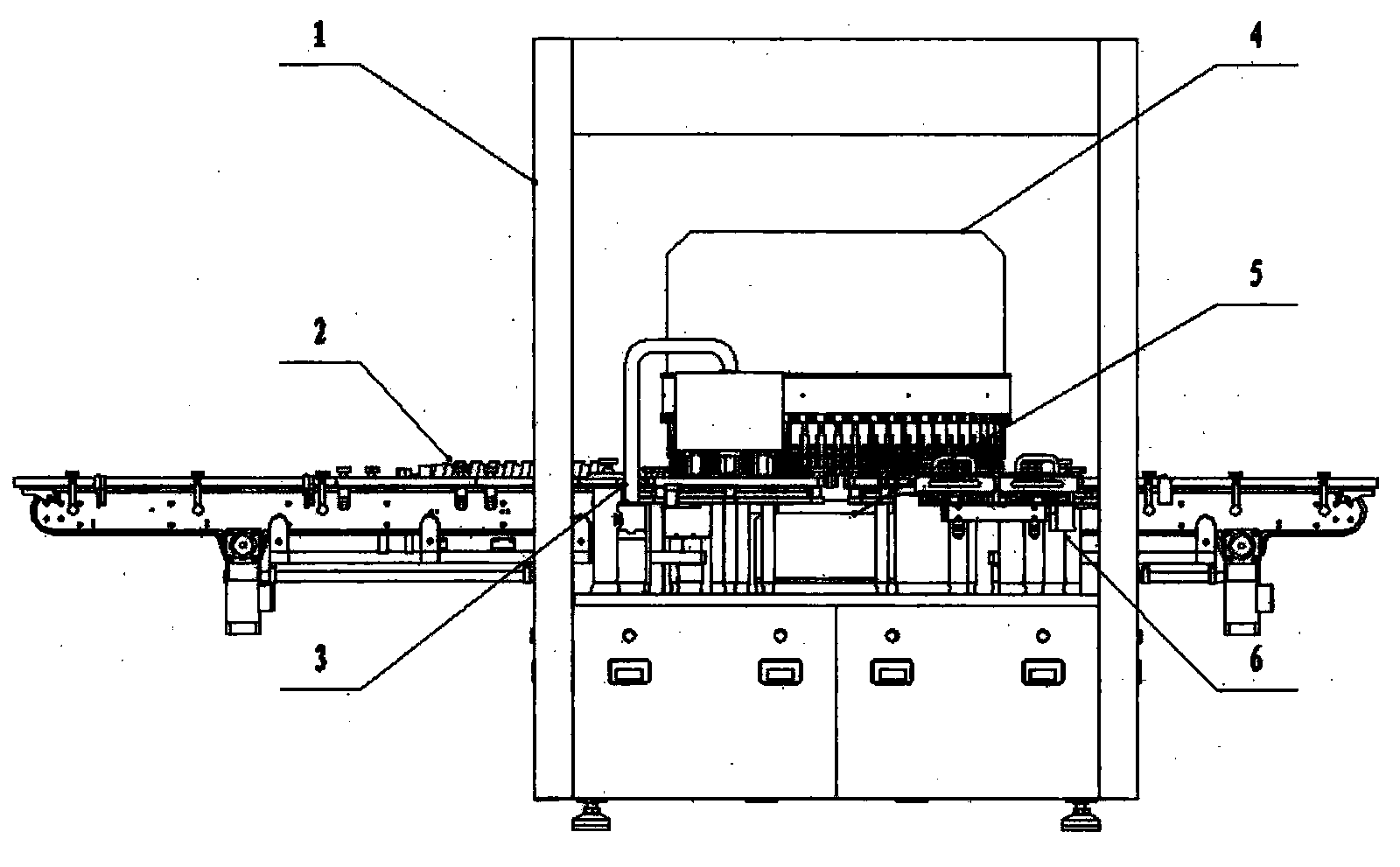

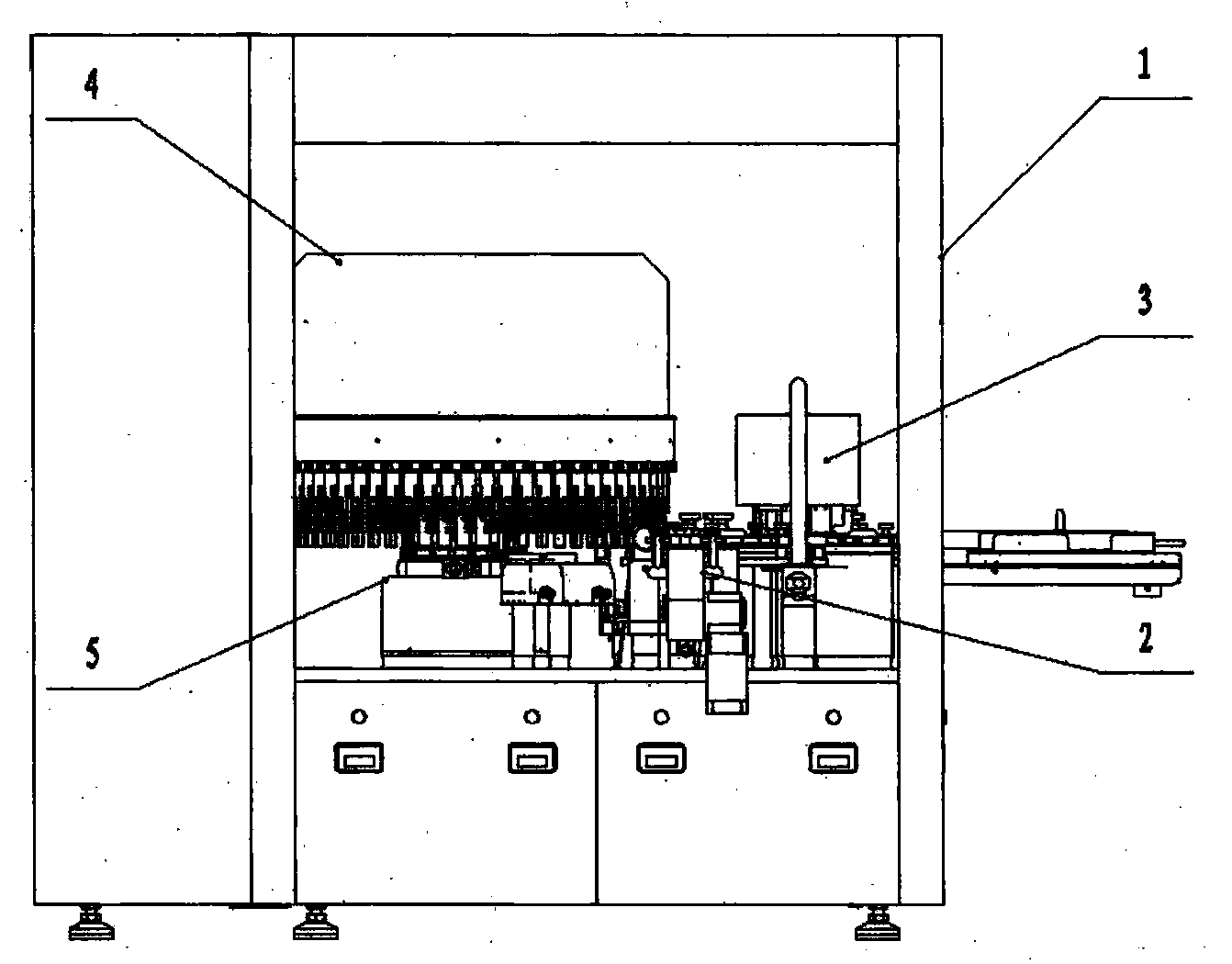

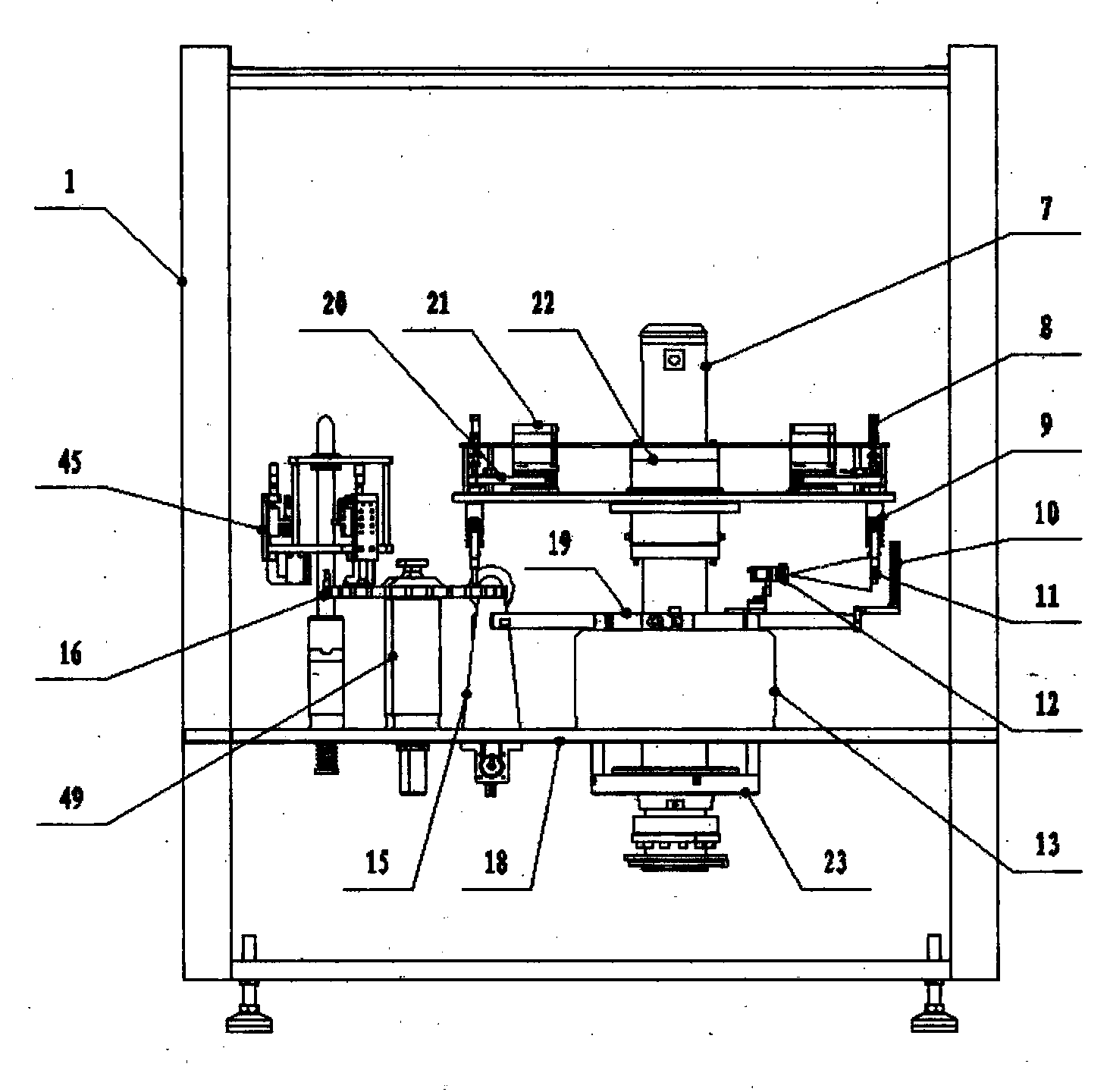

[0042] Such as figure 1 with figure 2 As shown, a kind of lyophilized vial without base type light inspection machine provided by the present invention is composed of rack system 1, feeding system 2, vial head inspection system 3, main shaft turret system 4, following camera system 5, output The material system 6 and the control system are composed of several parts. Among them, the feeding system 2, the vial head inspection system 3, the main shaft turret system 4, the follow-up camera system 5 and the discharge system 6 are installed on the main base plate 18 of the rack system 1, and the follow-up camera system 5 passes through several The bolts are fixed on the main base plate 18 . The motor following the camera system 5 is a hollow motor, coaxial with the main shaft turret system 5 during installation.

[0043] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com