Composite Drilling Method for Drag and Torsion Reduction in Complex Structure Wells

A technology with complex structure and resistance drop, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of high cost of rotary steerable drilling technology, high drilling conditions, high frictional resistance and difficult WOB, etc. , to reduce the probability of sticking accidents, improve drilling efficiency, and save drilling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method of the present invention will be further described in conjunction with the accompanying drawings.

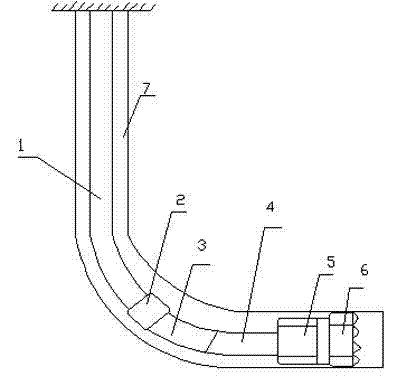

[0017] Such as figure 1 As shown, the main drilling tool assembly for wear and drag reduction drilling is the upper drilling tool (drill string) 1, the measurement-while-drilling drilling tool assembly 3, between the upper drilling tool 1 and the measurement-while-drilling drilling tool assembly 3, the A drag and torque reducer 2 is properly added, the bottom of the measurement-while-drilling drill tool assembly 3 is connected to the mud power motor 4, and a counter torque balance device 5 is added between the mud power motor 4 and the drill bit 6.

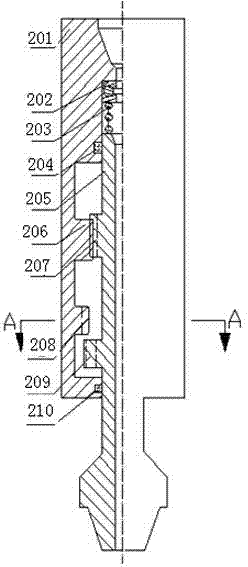

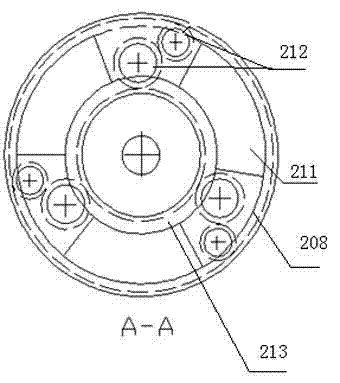

[0018] Such as figure 2 , the mandrel 205 is installed inside the housing 201, the bearing 202 and the spring 203 are installed between the upper end of the mandrel 205 and the housing 201, the housing spline groove 206 cooperates with the mandrel spline 207, and the ring gear 208 cooperates with the planetary ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com