Method for improving crease resistance and shrinkage resistance of Lyocell bamboo fiber

A bamboo fiber and performance technology, applied in fiber processing, plant fiber, textile material processing and other directions, can solve the problems of high shrinkage, easy wrinkling, dimensional instability, etc., to achieve low cost, reduce deformation, and improve wrinkle resistance. The effect of shrinking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Changes in anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics under different finishing conditions

[0025] Take the resin finishing agent A with a concentration of 50g / L, and the penetrating agent JFC at 2g / L, and double-dip and second-roll the fabric (the squeeze rate is 80%) with the finishing agent → drying (90°C, 6min) → baking (150°C, 3min ) → post-processing

[0026] Take concentration as 60g / L2D resin (dimethylol dihydroxyethylene urea) finishing agent, add 12g / L catalyst MgCl 2 , 2g / L penetrating agent JFC, two-dipping and two-rolling of the fabric (rolling liquid rate 80%) finishing agent → drying (80°C, 8min) → baking (150°C, 4min) → post-treatment

[0027] Determination of changes in anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics.

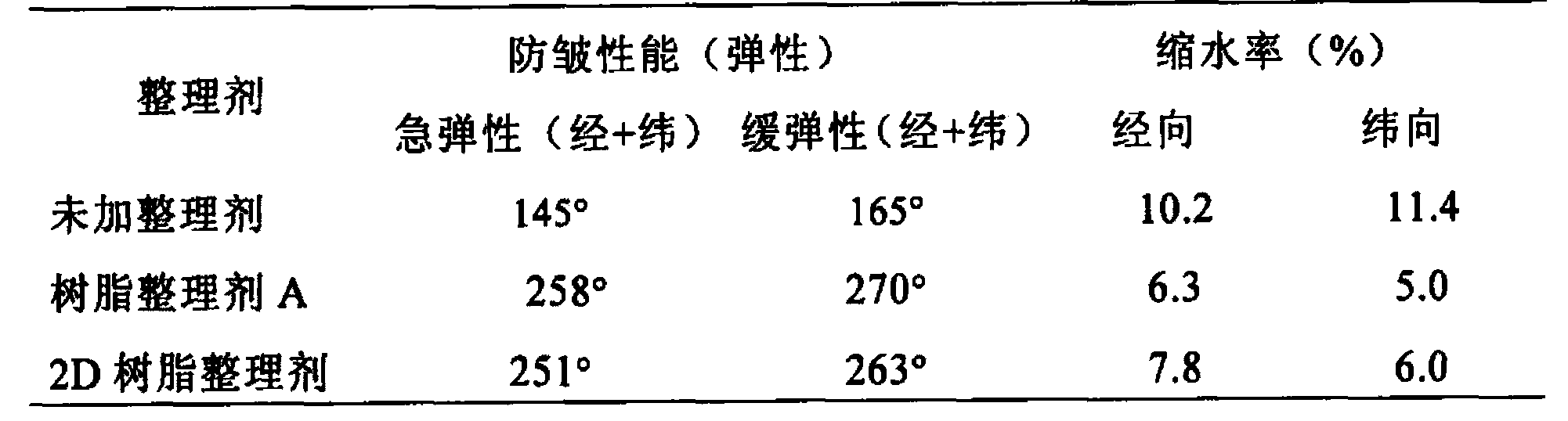

[0028] Table 1 Effects of different finishing agents on the anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics

[0029]

[0030] It can be seen fro...

Embodiment 2

[0032] Release of formaldehyde from Lyocell bamboo fiber fabrics treated with different finishing agents

[0033] Take the resin finishing agent A with a concentration of 50g / L, and the penetrating agent JFC at 2g / L, and double-dip and second-roll the fabric (the squeeze rate is 80%) with the finishing agent → drying (90°C, 6min) → baking (150°C, 3min ) → post-processing

[0034] Take concentration as 60g / L2D resin (dimethylol dihydroxyethylene urea) finishing agent, add 12g / L catalyst MgCl 2 , 2g / L penetrating agent JFC, two-dipping and two-rolling the fabric (rolling liquid rate 80%) finishing agent → drying (80°C, 8min) → baking (150°C, 4min-5min) → post-treatment

[0035] Determination of changes in anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics.

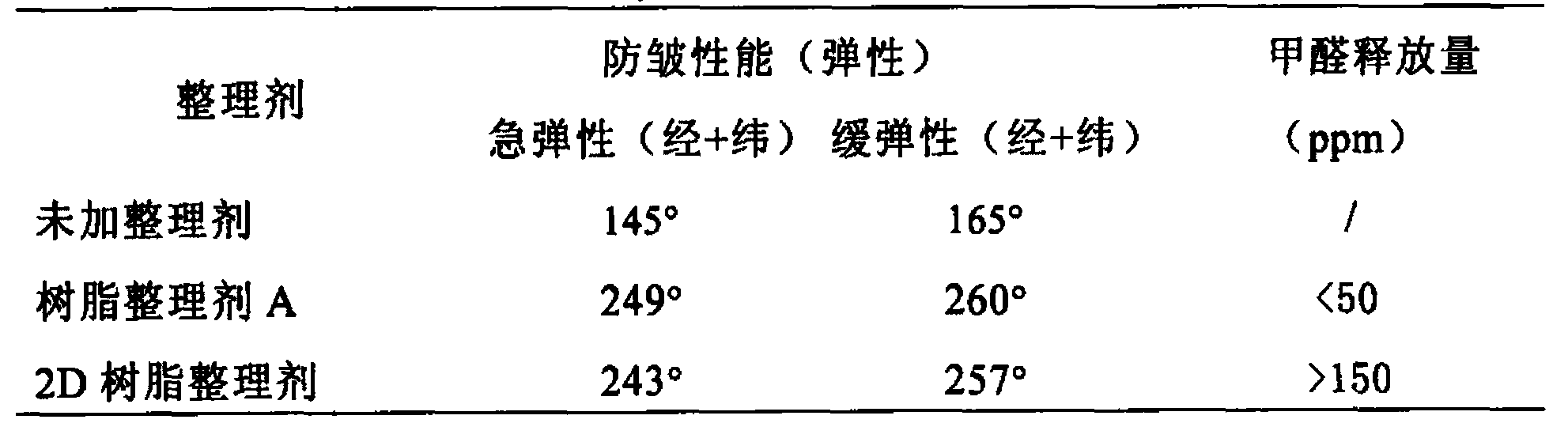

[0036] Table 2 Effects of different baking temperatures on the anti-wrinkle and anti-shrinkage and formaldehyde release of Lyocell bamboo fiber fabrics

[0037]

Embodiment 3

[0039] Changes in anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics after adding softener

[0040] Take the concentration of 50g / L resin finishing agent A, 15g / L silicone body fatty alcohol softener CFC, penetrating agent JFC 2g / L, two-dipping and two-rolling the fabric (rolling liquid rate 80%) finishing agent → drying (90 ℃ , 6min)→baking (150℃, 3min)→post-processing

[0041] Take concentration as 60g / L2D resin (dimethylol dihydroxyethylene urea) finishing agent, add 12g / L catalyst MgCl 2 , 15g / L silicone fatty alcohol softener CFC, 2g / L penetrating agent JFC, the fabric is dipped and rolled twice (80% of liquid rolling rate) finishing agent→drying (80°C, 8min)→baking (150°C , 4min) → post-processing

[0042] Determination of changes in anti-wrinkle and anti-shrinkage properties of Lyocell bamboo fiber fabrics.

[0043] Table 3 The effect of softener on the anti-wrinkle and anti-shrinkage performance of Lyocell bamboo fiber fabric

[0044]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com