A kind of sericin organic acid finishing solution and its skin-friendly finishing method for cotton fabrics

A technology of organic acid and finishing liquid, applied in the directions of plant fiber, fiber treatment, textile and papermaking, etc., can solve the problems of poor environmental protection and comfortable function, and achieve the effect of improving anti-wrinkle and anti-shrinking performance, high added value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

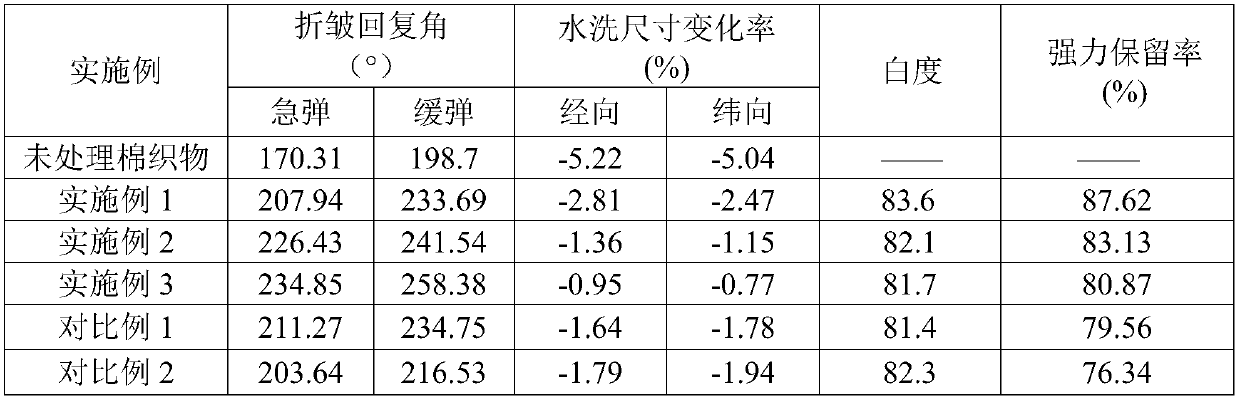

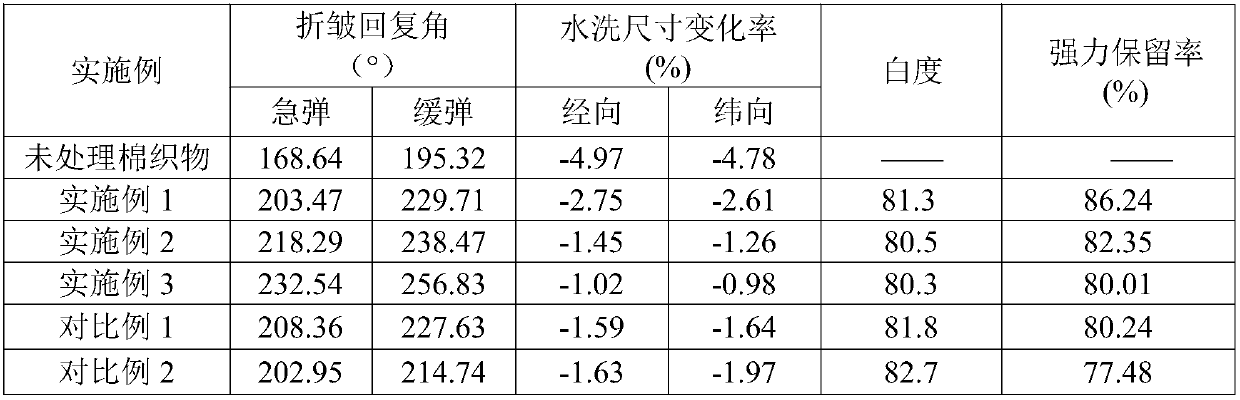

Examples

Embodiment 1

[0025] 1. Silk organic acid degumming: degumming mulberry (tussah) silk or its fabrics with butane tetracarboxylic acid, degumming organic acid 10g / L, JFC 5g / L, degumming temperature 98°C, time 60min, liquor ratio 1: 10. Obtain silk degumming solution.

[0026] 2. Preparation of finishing solution: add ethylenediaminetetraacetic acid sodium salt and nano-TiO to the above silk degumming solution 2 , the prepared concentration is 5g / L sodium ethylenediamine tetraacetate and 0.2g / L nano-TiO 2 sericin organic acid finishing solution.

[0027] 3. Cotton fabric finishing: immerse the cotton fabric in the sericin organic acid finishing solution in step 2, two dipping and two rolling, the pressure is 0.5kg / cm 2 , the liquid-carrying rate is 90%, pre-baked in a blast oven at 70°C for 10 minutes, stagnated for 1 minute, then baked at 160°C for 2 minutes, washed to neutral, and then dried at a low temperature of 25°C After drying, the skin-friendly cotton fabric of the present inventi...

Embodiment 2

[0029] 1. Silk organic acid degumming: degumming mulberry (tussah) silk or its fabrics with maleic anhydride, degumming organic acid 40g / L, JFC 3g / L, degumming temperature 95°C, time 30min, liquor ratio 1:40, Obtain silk degumming liquid.

[0030] 2. Preparation of finishing solution: add ethylenediaminetetraacetic acid sodium salt and nano-TiO to the above silk degumming solution 2 , the prepared concentration is 10g / L sodium ethylenediamine tetraacetate and 0.5g / L nano-TiO 2 sericin organic acid finishing solution.

[0031] 3. Cotton fabric finishing: immerse the cotton fabric in the sericin organic acid finishing liquid in step 2, two dipping and two rolling, the pressure is 0.9kg / cm 2 , with a liquid-carrying rate of 80%, pre-baked in a blast oven at 85°C for 5 minutes, stagnated for 1 minute, then baked at 165°C for 4 minutes, washed to neutral, and then dried at a low temperature of 25°C After drying, the skin-friendly cotton fabric of the present invention is obtaine...

Embodiment 3

[0033] 1. Silk organic acid degumming: degumming mulberry (tussah) silk or its fabrics with citric acid, degumming organic acid 60g / L, JFC 2g / L, degumming temperature 90°C, time 15min, bath ratio 1:20, obtained Silk degumming solution.

[0034] 2. Preparation of finishing solution: add ethylenediaminetetraacetic acid sodium salt and nano-TiO to the above silk degumming solution 2 , the prepared concentration is 20g / L sodium ethylenediamine tetraacetate and 1.0g / L nano-TiO 2 sericin organic acid finishing solution.

[0035] 3. Cotton fabric finishing: immerse the cotton fabric in the sericin organic acid finishing solution in step 2, two dipping and two rolling, the pressure is 1.5kg / cm 2 , the liquid-carrying rate is 70%, pre-baked in a blast oven at a temperature of 75°C for 5 minutes, stagnated for 1 minute, and then baked at a temperature of 165°C for 5 minutes, washed to neutral, and then dried at a low temperature of 30°C After drying, the skin-friendly cotton fabric o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com