High-efficiency heat transfer nano-copper material and preparation method thereof

A nano-copper, high-efficiency technology, applied in the field of high-efficiency heat transfer nano-copper and its preparation, can solve the problems of poor wear resistance, oxidation resistance and corrosion resistance, decreased thermal conductivity of copper materials, energy waste, etc., and achieve low cost , good hydrophilicity, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

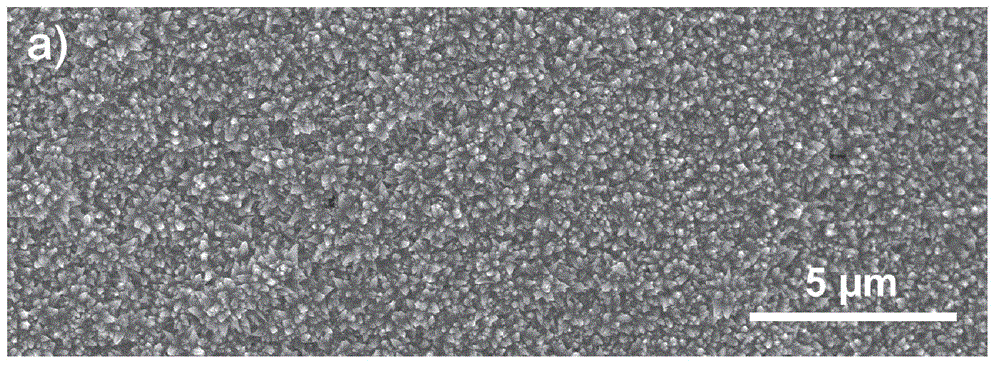

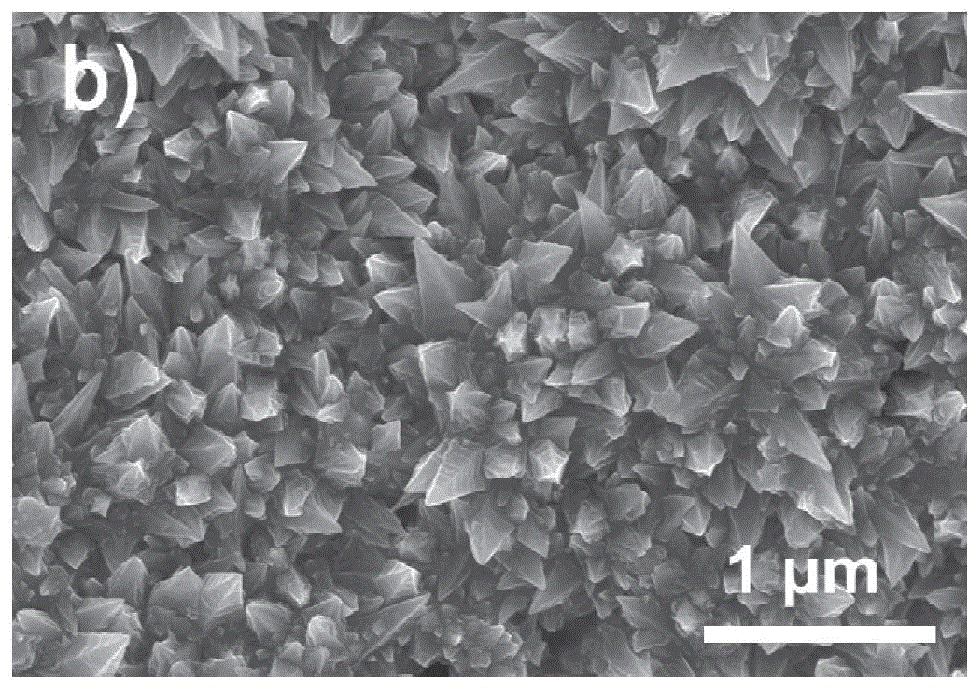

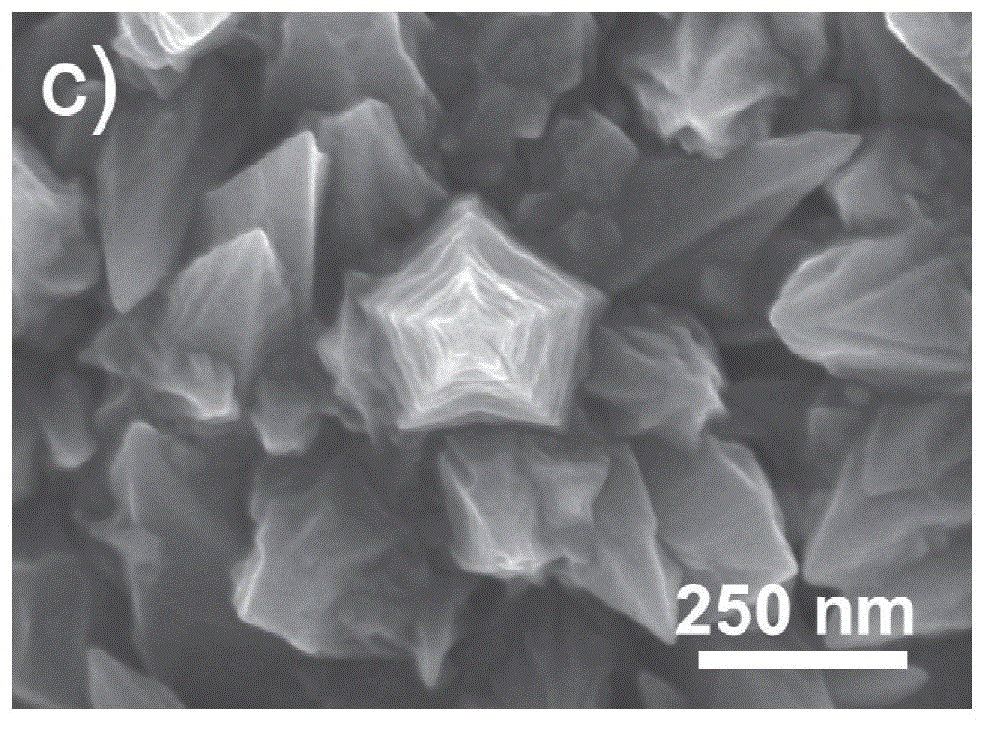

[0044] The preparation method of the copper material of the present invention mainly includes processes such as pretreatment of the substrate surface and electrochemical deposition, especially in the electrochemical deposition process, by controlling the experimental conditions such as the material concentration of the electrolyte, the deposition time, and the deposition current, copper can be realized. Controlling the structure of ultra-thin and super-wetting nano- or micro-nano composite porous nickel film on the surface of materials.

[0045] In a more preferred embodiment, the preparation method may include: taking the counter electrode, the working electrode mainly composed of copper and the reference electrode and placing them in a weakly acidic nickel salt electrolyte at 60°C to form a reducing system, and A certain reduction current is applied between the working electrode and the counter electrode to carry out the electrodeposition reaction of nickel on the copper surf...

Embodiment 1

[0062] (1) Carry out degreasing and polishing treatment on the surface of the copper sheet with a purity of 99.9% in an acidic solution at 60° C., then rinse it with ultrapure water, and dry it under high-purity nitrogen for later use. The degreasing polishing liquid used is an acidic polishing liquid, wherein the components and their volume ratios are respectively: acetic acid: phosphoric acid: nitric acid: water=13:13:2:2.

[0063] (2) Before electroplating, place the copper sheet in sulfuric acid or hydrochloric acid with a volume concentration of 20% to activate for 10-20 seconds, rinse it with ultrapure water, and then put it into the plating solution for electrodeposition reaction. The surface-treated copper sheet was used as the working electrode, the platinum sheet with a purity of 99.9% was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode. The distance between the two electrodes is controlled to be 60mm, and the constant cur...

Embodiment 2

[0070] (1) Degrease the surface of the copper table in an acidic solution at 60°C, then rinse it with ultrapure water, and dry it under high-purity nitrogen for later use. The volume ratios of the components in the used acidic polishing liquid are: acetic acid: phosphoric acid: nitric acid: water = 13:13:2:2.

[0071] (2) Before electroplating, put the copper platform in sulfuric acid with a volume concentration of 20% to activate for 10-20s, then rinse it with ultrapure water, and put it into the plating solution for electroplating. A copper platform was used as the working electrode, a platinum sheet with a purity of 99.9% was used as the counter electrode, and an Ag / AgCl electrode was used as the reference electrode. The distance between the two electrodes was controlled to be 60 mm, and the constant current electrodeposition reaction was carried out in a constant temperature water bath at 60° C., the current was controlled at 100 mA, and the duration was 45 min. The elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com