Method for reducing ammonia nitrogen content in polymyxin E fermentation liquor

A technology of polymyxin and ammonia nitrogen content, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as unfavorable long-term development of enterprises, increase the burden of sewage treatment, etc., and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

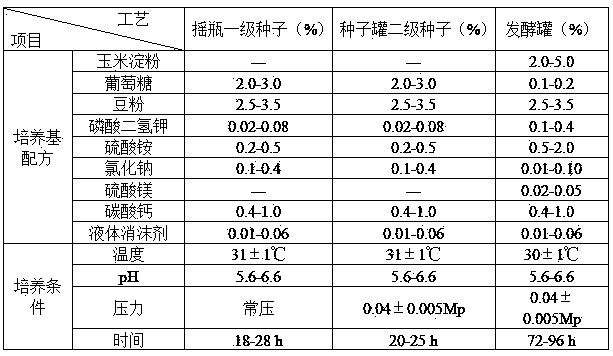

Image

Examples

Embodiment 1

[0026] A 50L Bailun stainless steel fermentation tank is filled with 30L fermentation broth, inoculated with 2-5% seed broth, and after 8 hours of transfer from the fermentation broth, the ammonia water is added to automatically control the pH between 5.6-6.6 and the fermentation is completed. The fermentation effect of polymyxin E is The price is 512,000 U / mL, and the ammonia nitrogen content of the tank in the fermentation broth is about 500mg / 100mL.

Embodiment 2

[0028] A 50L stainless steel fermentation tank is filled with 30L of fermentation broth, inoculated with 2-5% of the seed liquid, after 15 hours of transfer from the fermentation broth, the flow of ammonia is automatically controlled to pH 5.6, and after 60 hours of transfer from the fermentation broth, the flow of ammonia is stopped. The pH was controlled to 5.6 by adding 10% sodium hydroxide solution. After 30 hours of adding, the fermentation titer of polymyxin E was 504,000 U / mL. Compared with the existing technology, the amount of ammonia water is reduced by about 30%, and the ammonia nitrogen content in the fermentation broth is reduced from about 500mg / 100mL to about 300mg / 100mL.

Embodiment 3

[0030] A 50L stainless steel fermentation tank is filled with 30L fermentation broth, inoculated with 2-5% of the seed broth, and after 10 hours of transfer from the fermentation broth, the flow of ammonia is automatically controlled to pH 6.0, and after 30 hours of transfer from the fermentation broth, the flow of ammonia is stopped. To control the pH to 6.0 by adding 20% sodium hydroxide solution, and then adding for 60 hours, the polymyxin E fermentation potency was 518,000 U / mL. Compared with the existing technology, the amount of ammonia water is reduced by about 32%, and the ammonia nitrogen content in the fermentation broth is reduced from about 500mg / 100mL to about 260mg / 100mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com