Preparation method and application of two-dimensional nano rare earth borate laccase sensor

A two-dimensional nano, borate technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as desorption activity, loss, laccase leakage, etc., and achieve simple methods, easy large-scale production, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

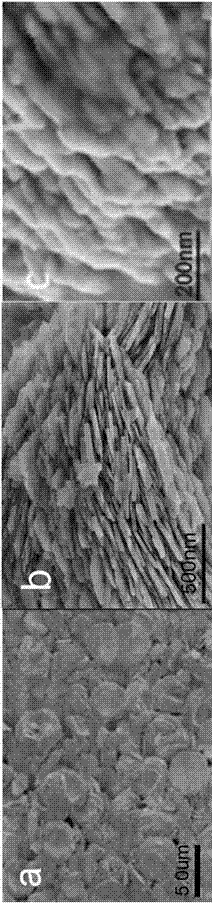

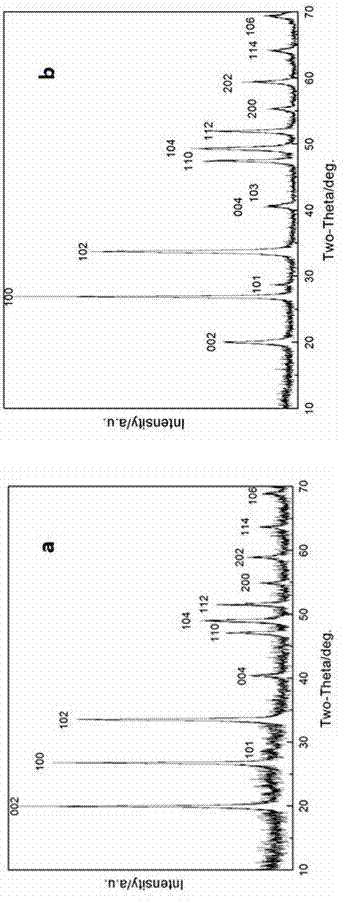

[0029] first, Rare earth borate SmBO 3 Preparation of nanosheets:

[0030] In this experiment, a 20 mL sealed hydrothermal reaction kettle lined with polytetrafluoroethylene was used to prepare samarium borate micro-nano materials by solid-state hydrothermal method under medium temperature conditions. The detailed reaction process is described as follows: Add 209.2 mg Sm sequentially to a clean and dry PTFE liner 2 o 3 (0.6 mmol), 44.5 mg H 3 BO 3 (0.72 mmol, 10% excess) and 14 ml H 2O; then put the liner into an ultrasonic cleaner to disperse for 15 min; take out and wipe off the moisture outside the liner, put it into a reaction kettle and seal it; put the closed reaction kettle into a temperature-controlled constant temperature drying oven for 200 ℃ and kept for 36 hours; after the reaction was completed, it was naturally cooled to room temperature, and then separated and washed with a centrifugal separator. After washing 4 times with deionized water and 4 times w...

Embodiment 2

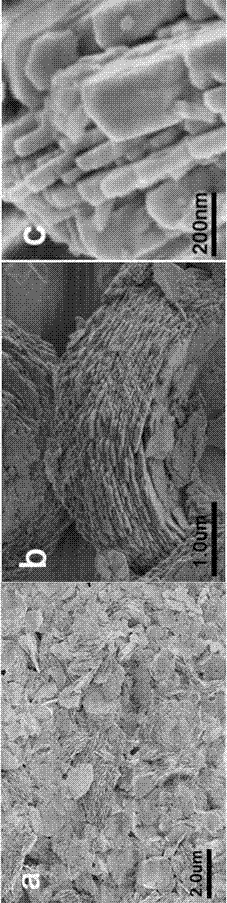

[0038] first, Rare earth borate GdBO 3 Preparation of nanosheets:

[0039] In this experiment, a 20 mL sealed hydrothermal reaction kettle lined with polytetrafluoroethylene was used to prepare samarium borate micro-nano materials by solid-state hydrothermal method under medium temperature conditions. The detailed reaction process is described as follows: 217.5 mg Gd was sequentially added to a clean and dry PTFE liner 2 o 3 (0.6 mmol), 44.5 mg H 3 BO 3 (0.72 mmol, 10% excess) and 14 ml H 2 O; then put the liner into an ultrasonic cleaner to disperse for 15 min; take out and wipe off the moisture outside the liner, put it into a reaction kettle and seal it; put the closed reaction kettle into a temperature-controlled constant temperature drying oven for 200 ℃ and kept for 36 hours; after the reaction was completed, it was naturally cooled to room temperature, and then separated and washed with a centrifugal separator. After washing 4 times with deionized water and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com