Anti-phosphor deposition high thixotropic LED (light-emitting diode) jelly glue

A technology of jelly glue and phosphor powder, applied in luminescent materials, electrical components, circuits, etc., can solve the problems of obvious agglomeration, unfavorable operation, viscosity thickening, etc., to simplify the packaging process, solve color temperature deviation, and high plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation process of jelly gum is as follows:

[0046] (1) Preparation of coupling agent KH560 hydrolysis solution: Take 5mL methanol and 45mL distilled water and mix uniformly, add 0.1g (2g / L) glycerol dropwise to the system, adjust the solution pH=4 with acetic acid, and then add 5mL KH560 , Magnetic stirring at room temperature for 2h. The electrical conductivity is measured to be 90μS / cm, which proves that the above hydrolysis method can fully hydrolyze the coupling agent.

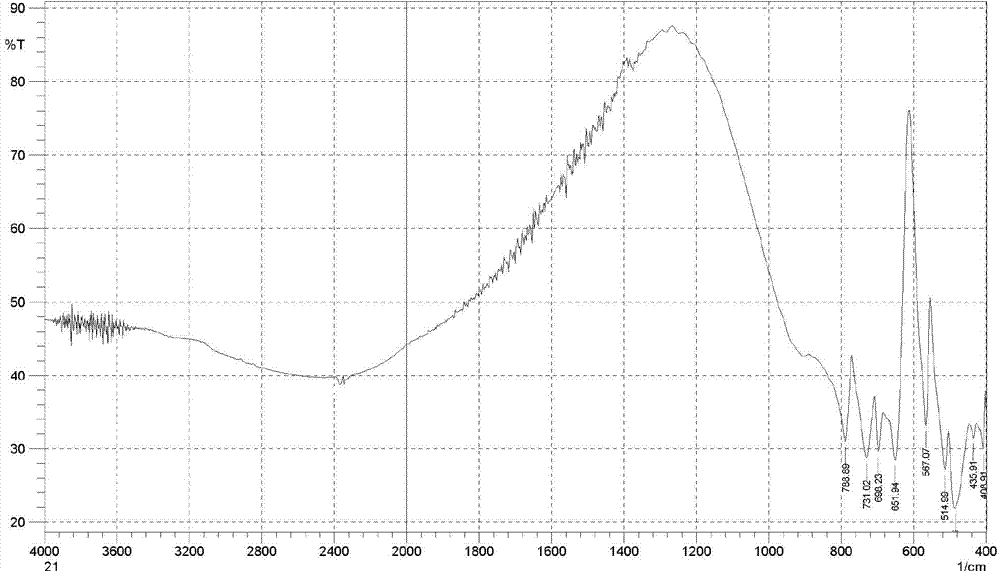

[0047] (2) Treatment of fumed silica: Take 100g of Wacker H30 in a round bottom flask, add 100 mL of toluene and 1g of the coupling agent hydrolysate prepared in step (1), stir and reflux at 110°C for 3h. After the reaction was completed, the toluene was removed by rotary evaporation under reduced pressure, and the toluene was dried in an oven at 60° C. overnight.

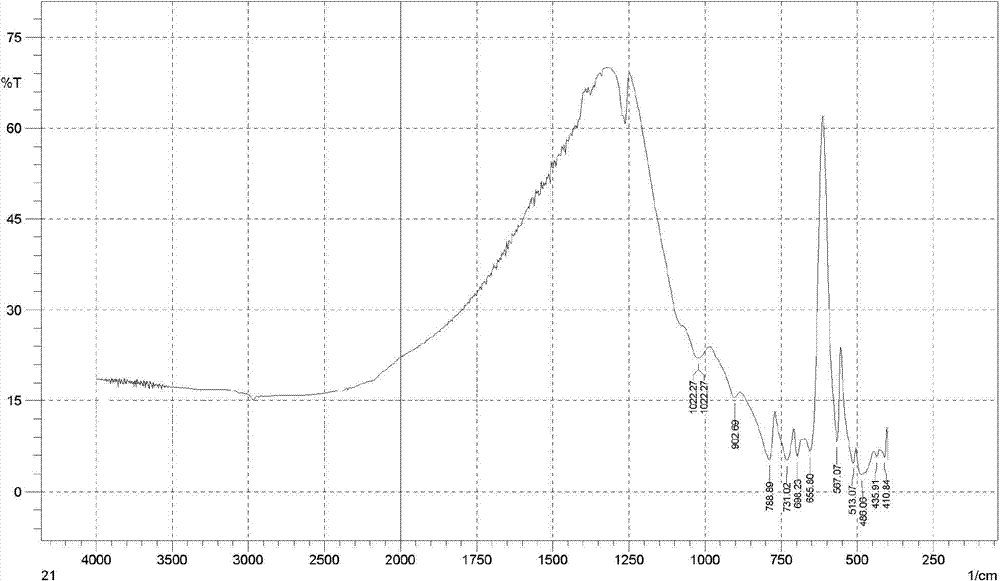

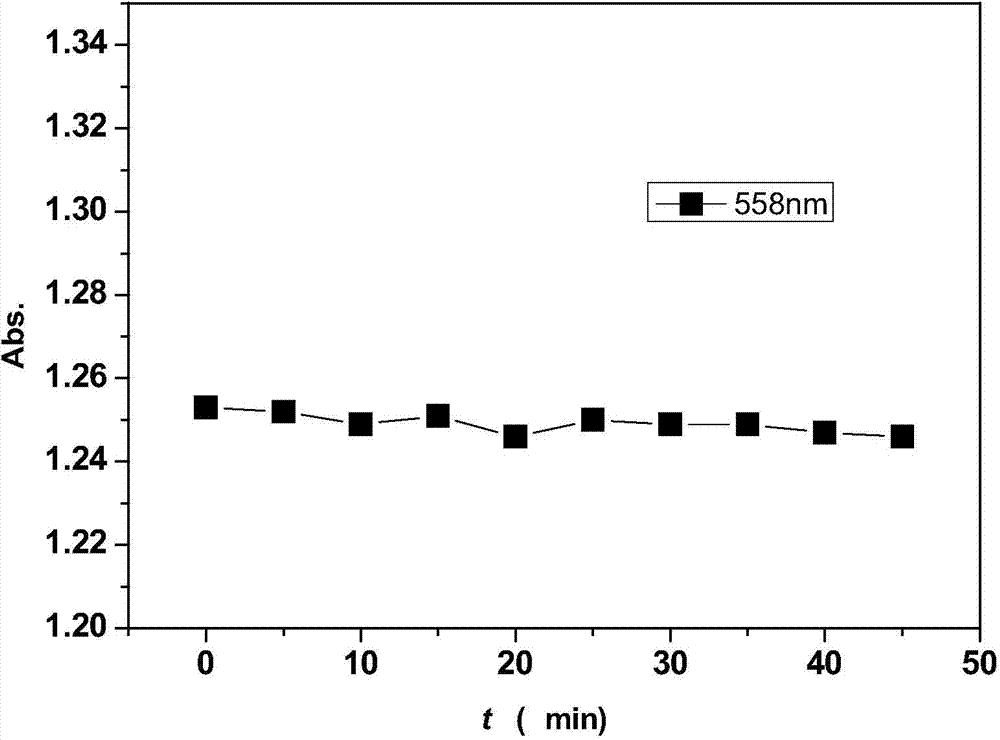

[0048] (3) Modification of aluminate phosphor YAG-04 (American Intermatix company): Weigh 7.8g YAG-04, add 15mL distilled water, a...

Embodiment 2

[0053] (1) Preparation of coupling agent KH560 hydrolysis solution: Take 15mL methanol and 80mL distilled water and mix uniformly, add 0.3g glycerol dropwise to the system, adjust the solution pH=2 with acetic acid, then add 5mL KH560, and stir magnetically at room temperature 3h. The conductivity is measured to be 88μS / cm, which proves that the above hydrolysis method can fully hydrolyze the coupling agent.

[0054] (2) Treatment of fumed silica: Take 200g of Wacker H20 in a round bottom flask, add 250mL of methanol and 1g of the KH560 hydrolysate prepared in step (1), stir and reflux at 120°C for 2h. After the reaction was completed, the methanol was removed by rotary evaporation under reduced pressure and dried in an oven at 60°C overnight.

[0055] (3) Modification of aluminate phosphor YAG-04 (Intermatix, USA): Weigh 4.5g YAG-04, add 15mL distilled water, and ultrasonically disperse for 9min to obtain YAG-04 solution; then add 0.3g dropwise step (1 ) The prepared KH560 hydro...

Embodiment 3

[0060] (1) Preparation of coupling agent KH570 hydrolysis solution: take 15mL methanol and 80mL distilled water and mix uniformly, add 0.3g glycerol dropwise to the system, adjust the solution pH=2 with acetic acid, then add 5mL KH570, stir magnetically at room temperature 3h. The conductivity is measured to be 85μS / cm, which proves that the above hydrolysis method can fully hydrolyze the coupling agent.

[0061] (2) Treatment of fumed silica: Take 200g of Cabot TS720 in a round bottom flask, add 250mL of xylene and 1g of the KH570 hydrolysate prepared in step (1), stir at 120°C and reflux for 2h. After the reaction was completed, the xylene was removed by rotary evaporation under reduced pressure and dried in an oven at 60°C overnight.

[0062] (3) Modification of silicate phosphor O5742 (Intermatix, USA): Weigh 4.5g of O5742, add 15mL of distilled water, and ultrasonically disperse for 9min to obtain O5742 solution; then add dropwise 0.3g of KH570 hydrolysate prepared in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com