Composite coloring agent and preparation method thereof

A dyeing agent and compound technology, applied in the direction of organic dyes, etc., can solve the problems of weak luminescence, complicated preparation process, poor fatigue resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

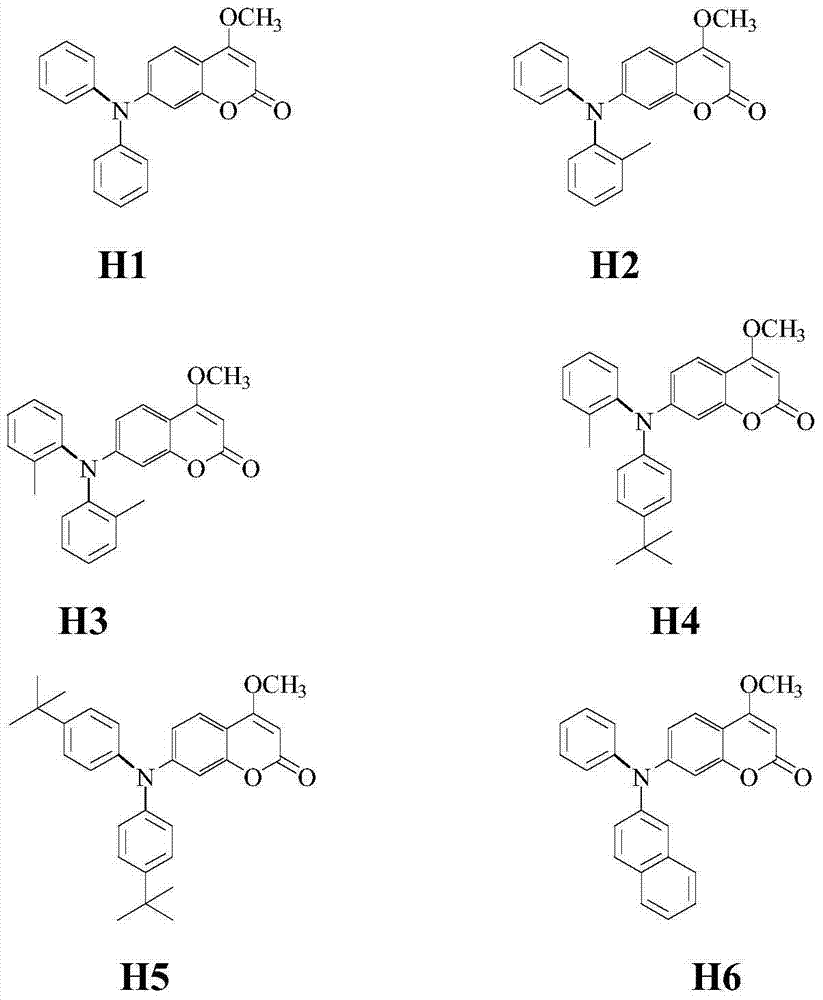

[0073] Place the reaction vessel in a water bath at 40°C, add 15 L of water, 0.5 mol of sodium dodecylbenzenesulfonate, 0.5 mol of N,N-dimethyldodecyl ammonium chloride, and 0.04 mol of the above-mentioned light Stabilizer, 0.15mol of the above-mentioned green light-emitting coumarin compound G1, 0.85mol of the above-mentioned blue light-emitting coumarin compound H1, stirred and dissolved evenly to form a uniform solution system; then add 20mol of styrene, 10mol of acrylonitrile, 3.5mol of methyl Glycidyl acrylate and 16.5mol sodium vinyl sulfonate are stirred vigorously to form a uniform emulsion; then potassium persulfate solution is added dropwise evenly (the amount of potassium persulfate solution is 50g of potassium persulfate dissolved in 200ml of water) and hydrogen phosphate Disodium solution (disodium hydrogen phosphate solution add-on is that 50g disodium hydrogen phosphate is dissolved in 250ml water), the rate of addition of potassium persulfate solution and disodi...

Embodiment 2

[0075] Except that the compound H1 of Example 1 was replaced by H2, Example 2 was carried out in the same manner as Example 1 to obtain a composite dyeing agent named as FH-2.

Embodiment 3

[0077] Example 3 was carried out in the same manner as in Example 1 except that the compound G1 in Example 1 was replaced by G2 to obtain a composite dye named FH-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com