Carbon nanotube-based magnetic organophosphorus molecularly-imprinted polymer and its preparation method and use

A technology of carbon nanotubes and molecular imprinting, which is applied in the field of separation analysis, can solve the problems of poor applicability of polymers, time-consuming pretreatment technology, and large consumption of organic solvents, so as to achieve good selectivity, shorten extraction and purification time, and avoid matrix impurities. interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

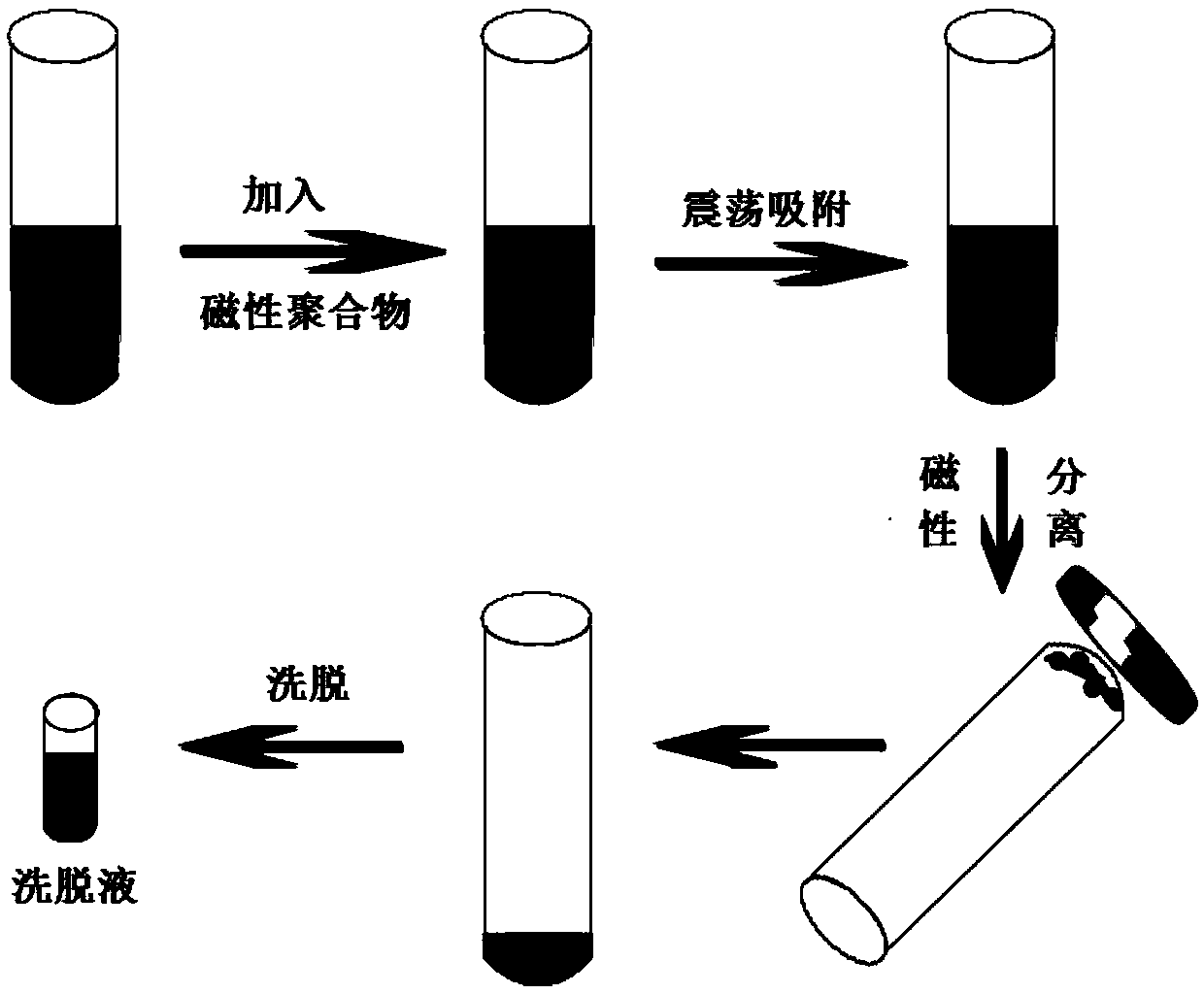

Method used

Image

Examples

specific Embodiment approach 1

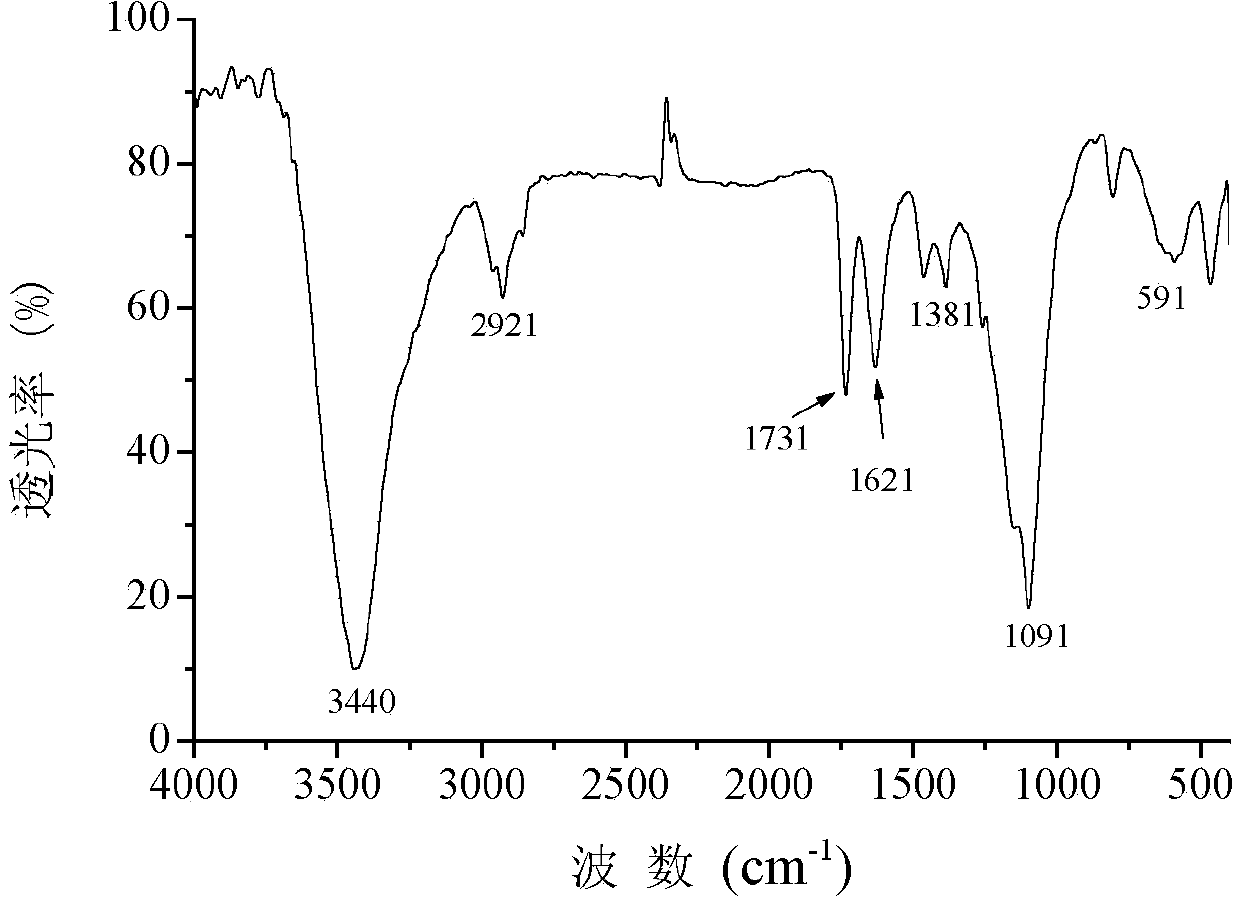

[0029] Embodiment 1: A carbon nanotube-based magnetic organophosphorus molecularly imprinted polymer of this embodiment includes carbon nanotubes, FeCl 3 ·6H 2 O, crosslinking agent and functional monomer.

[0030] The beneficial effect of this implementation mode:

[0031] In the present invention, carbon nanotubes are selected as the carrier, so that the final magnetic molecularly imprinted polymer has good dispersion properties.

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the crosslinking agent is ethylene glycol dimethacrylate or trimethylolpropane trimethacrylate; the functional monomer For methacrylic acid, acrylamide or 4-vinylpyridine. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: In this embodiment, a method for preparing a carbon nanotube-based magnetic organophosphorus molecularly imprinted polymer is carried out according to the following steps:

[0034]1. Mix carbon nanotubes and concentrated nitric acid evenly at a ratio of mass to volume of 0.8g: 100-200mL, stir the mixture magnetically in an oil bath at 80-90°C for 5-7 hours, and then activate the activated Wash the carbon nanotubes until they are neutral, and dry them at 50-70°C to obtain a powdery substance;

[0035] 2. Combine 0.3-0.6g of the powdered substance obtained in step 1 and 1.0-1.8g of FeCl 3 ·6H 2 O Mix evenly to obtain a mixture, add 60-100mL ethylene glycol solvent to the mixture, stir in an oil bath at 80-90°C until FeCl 3 ·6H 2 After O is completely dissolved, add 3.4~3.8g of sodium acetate, stir until the sodium acetate is completely dissolved, then stir for 2~3min, then transfer to the reaction kettle, and put the reaction kettle in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com