Electric-conduction ink containing graphene complex, and preparation method thereof

A technology of conductive ink and graphene, which is applied in ink, household utensils, applications, etc., can solve the problems of limited practical application and expensive graphene, and achieve the effects of improved stripping efficiency, good crystallization, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation of graphene composite: adding graphite, graphene stripping agent, acid, distilled water and zirconium beads with a particle size of 0.6-0.8mm into the container and mixing to obtain a mixed solution, ultrasonic stripping is carried out under the assistance of ultrasonic waves (per 1g graphene The ultrasonic unit power is 300-700W, and the peeling time is 10-50h); after the peeling, the zirconium beads are separated, centrifuged at 2000-4000rpm for 10-30min, and the supernatant liquid of the graphene composite is taken, filtered, washed and dried A graphene composite is obtained. Wherein, the mass ratio of the graphite, graphene stripping agent, distilled water and zirconium beads is 1: 0.1-0.2: 50-200: 50-500; the amount of the acid added is such that the pH of the mixed solution is 6.0-6.5 .

[0034] Preparation of conductive ink: Mix the graphene composite with other raw materials, and disperse them by ultrasonic vibration for at least 24 hours to obt...

Embodiment 1

[0036] Preparation of graphene stripping agent:

[0037] Add 1.0 grams of graphite, 0.15 grams of graphene stripping agent A, 100 grams of distilled water in a glass reaction vessel, adjust the mixed solution to pH=6.0-6.5 with hydrochloric acid, and then add 200 grams of 0.6-0.8mm zirconium beads .

[0038] Graphene stripper A

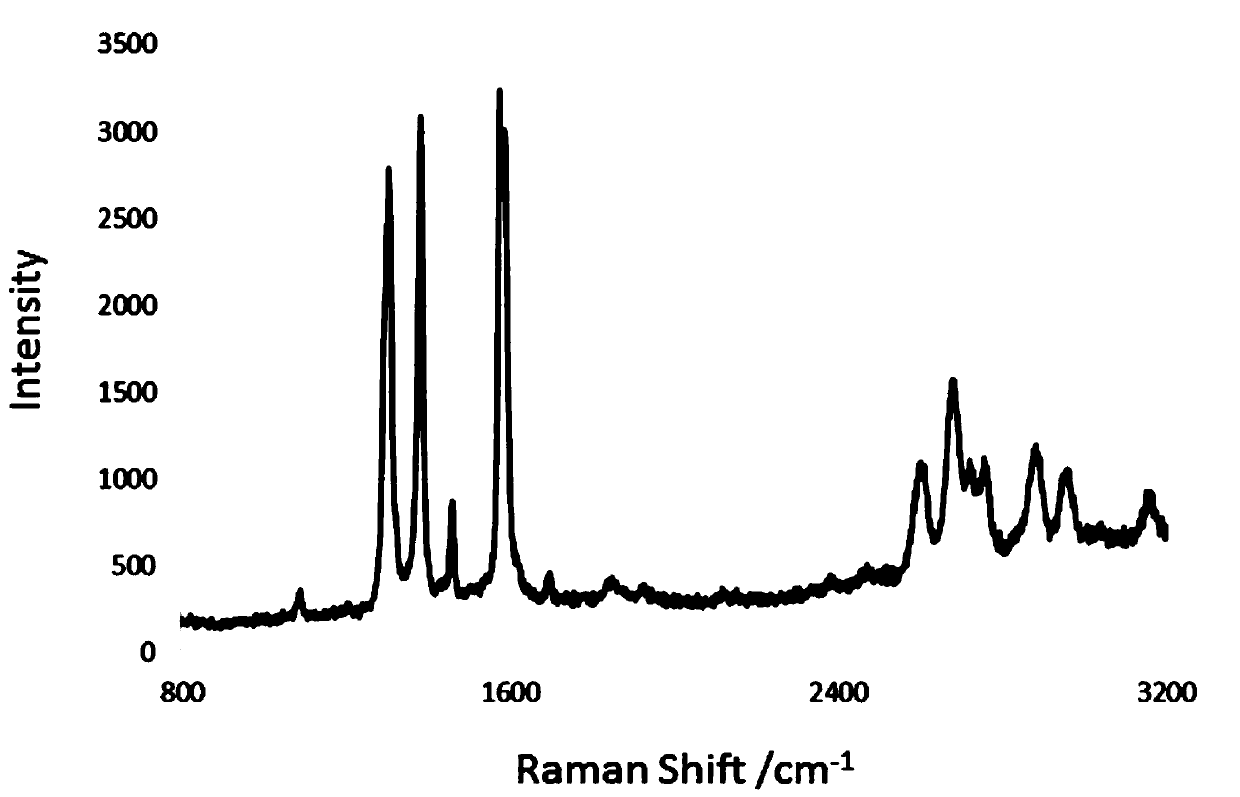

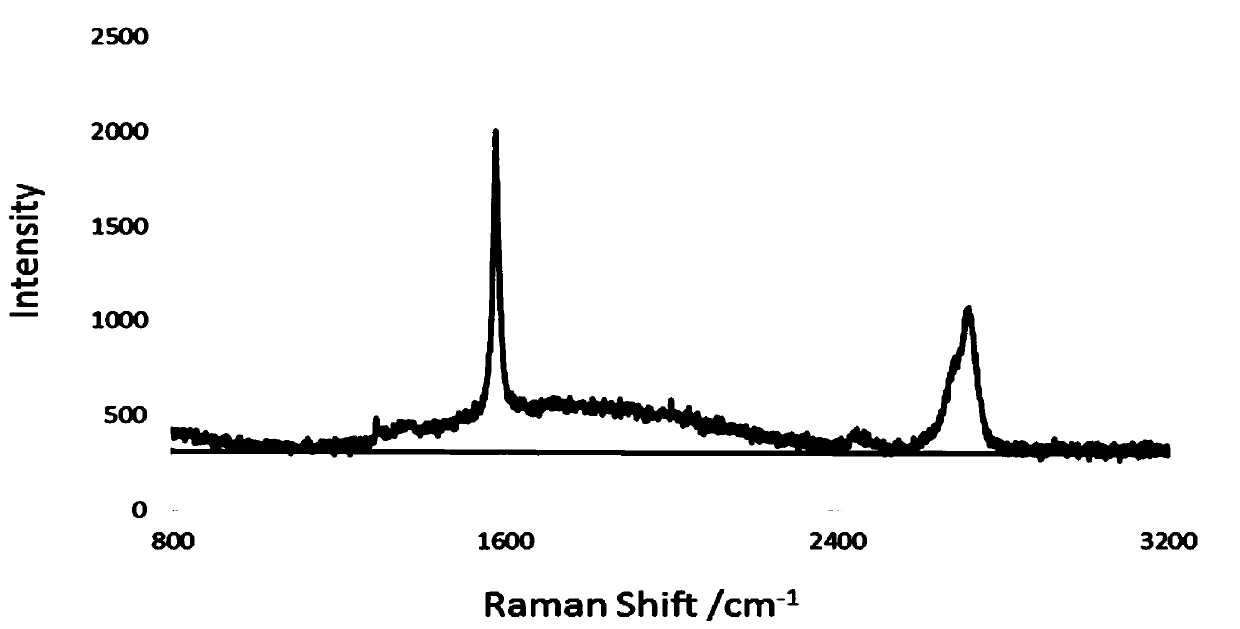

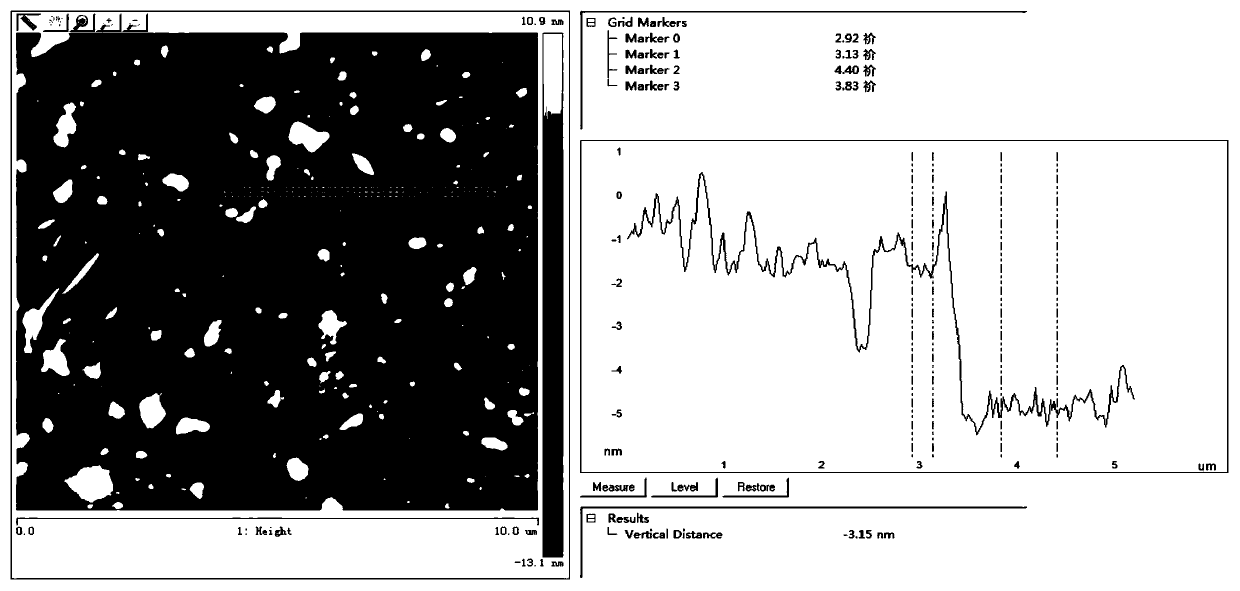

[0039] Use a 500-watt ultrasonic cleaner for 16 hours of ultrasonic peeling. After the stripping is completed, the zirconium beads are separated and centrifuged at 3000 rpm for 20 minutes. Take the graphene composite supernatant. Filter with a polytetrafluoroethylene membrane, wash with distilled water until the filtrate is colorless and neutral, collect the solid, then disperse in 50 ml of distilled water, and freeze-dry to obtain 0.16 g of graphene composite 1. The obtained graphene composite 1 tests the Raman spectrum, and obtains the Raman spectrum as figure 1 As shown, 1303, 1383, 1584cm -1 The peak is the Raman absorption peak of graphen...

Embodiment 2

[0043] Preparation of graphene stripping agent:

[0044] Add 1.0 grams of graphite, 0.15 grams of graphene stripping agent B, 100 grams of distilled water, adjust the dispersion to pH=6.0-6.5 with hydrochloric acid, and then add 200 grams of 0.6-0.8mm zirconium beads .

[0045] Graphene stripper B

[0046] Use a 500-watt ultrasonic cleaner for 16 hours of ultrasonic peeling. After the stripping is completed, the zirconium beads are separated and centrifuged at 3000 rpm for 20 minutes. Take the graphene composite supernatant. Filter with a polytetrafluoroethylene filter membrane, and wash with distilled water until the filtrate is colorless and neutral, collect the solid, then disperse in 50 ml of distilled water, and freeze-dry to obtain 0.14 g of graphene composite 2.

[0047] Production of conductive ink:

[0048] Into a 5ml glass bottle, add 0.083g of graphene composite 2, 0.017g of ethyl cellulose, 0.25g of pine oil, 0.3ml of xylene, and 0.2ml of methanol, and dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com