Preparation method of perfluoropropane

A technology of octafluoropropane and hexafluoropropene, which is applied in the field of preparation of octafluoropropane, which can solve the problems of equipment corrosion, increase equipment cost, and high equipment material requirements, and achieve the effects of reducing the severity, reducing material requirements, and inhibiting cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

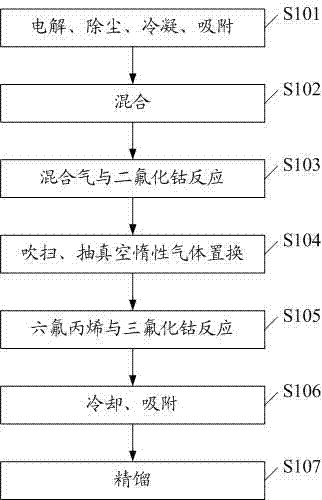

[0020] figure 1 It is a flowchart of the preparation method of octafluoropropane of the present invention.

[0021] Such as figure 1 As shown, the steps of the preparation method of octafluoropropane include in turn: electrolysis, dust removal, condensation, adsorption; mixing; reaction of mixed gas with cobalt difluoride; purging, vacuuming inert gas replacement; Cobalt reaction; cooling, adsorption; rectification.

[0022] Combine below figure 1 Specifically introduce the detailed steps of the preparation method of octafluoropropane:

[0023] S101. Potassium bifluoride is electrolytically treated in an electrolytic cell to obtain a fluorine gas mixture, and the fluorine gas mixture is sequentially subjected to dedusting, condensation, and adsorption treatments to purify the fluorine gas mixture as a raw material.

[0024] Electrolytic reaction formula: 2KHF 2 →2KF+H 2 +F 2

[0025] What needs to be explained here is that potassium bifluoride is electrolytically treat...

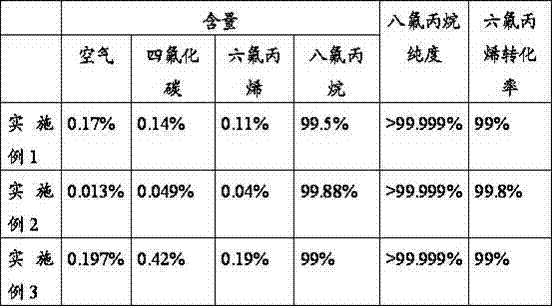

Embodiment 1

[0053] The reactor is a fixed bed reactor with internal heating and 8 temperature control points. In the mixed gas, the concentration of fluorine gas is 20%, and its production method is as follows:

[0054] A. Turn on the electrolytic cell, control the pressure of the electrolytic cell to a slight negative pressure, and obtain a fluorine gas mixture after electrolytic treatment of potassium bifluoride in the electrolytic cell, and then process the fluorine gas mixture in turn through dust removal, condensation, and adsorption treatments to purify it into fluorine gas as a raw material .

[0055] B. After the raw material fluorine gas is pressurized by a compressor, it is uniformly mixed with an inert gas to obtain a mixed gas, and the concentration of fluorine gas in the mixed gas is 20%.

[0056] C. Raise the temperature of the reactor to 300°C in advance, with 12.5Nm 3 The mixed gas is passed into the reactor at a flow rate of / h, and the pressure in the reactor is contro...

Embodiment 2

[0062] In this embodiment, the concentration of fluorine in the mixed gas is 40%, and the rest are the same as the method of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com