Circuit-board developing, electroplating and etching device

A technology for etching equipment and circuit boards, which is applied in the field of circuit board development, electroplating and etching equipment, can solve the problems of reducing the yield of the circuit board manufacturing process and increasing the cost of the circuit board manufacturing process, and achieves the effect of reducing the impact and improving the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

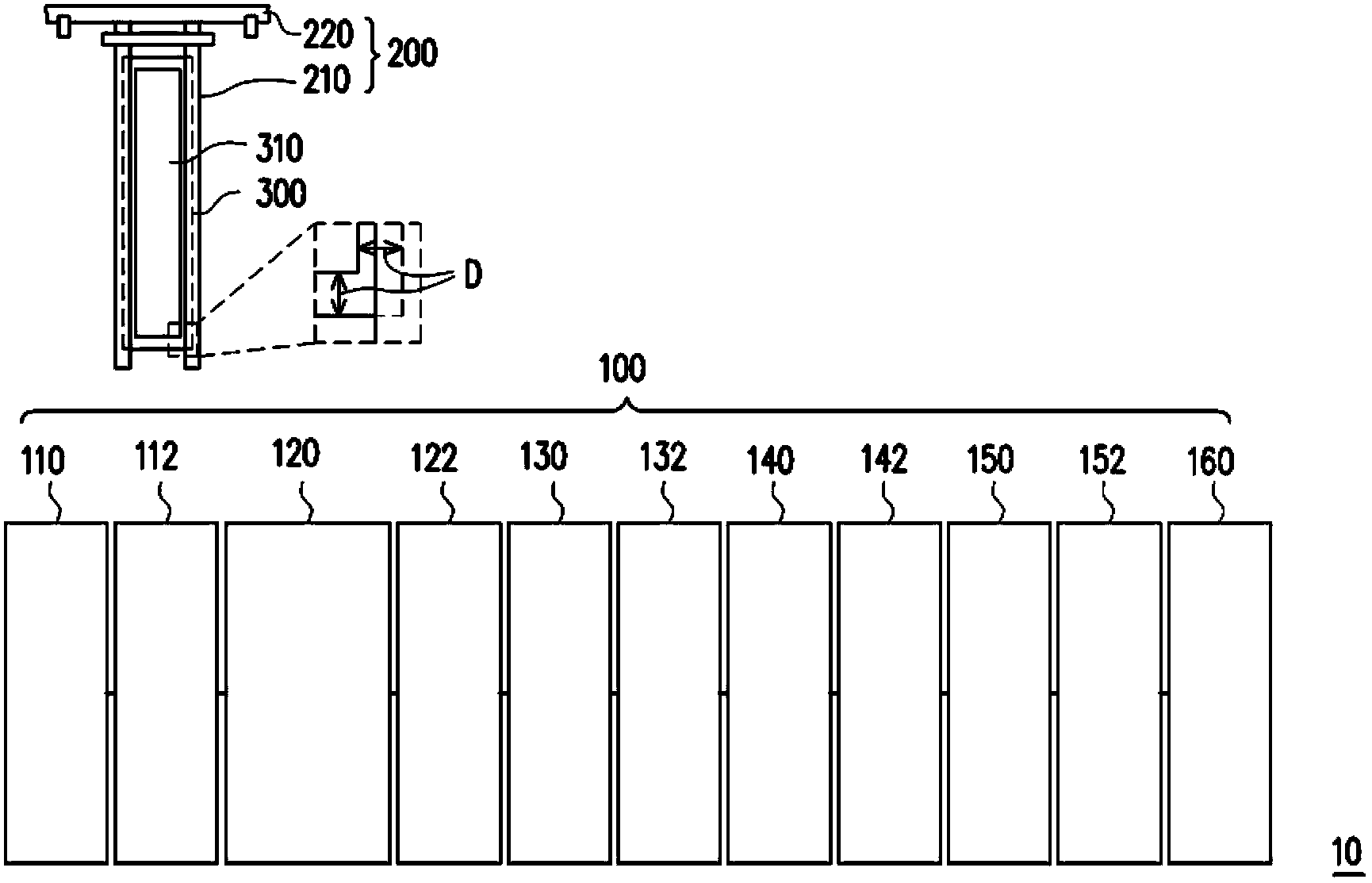

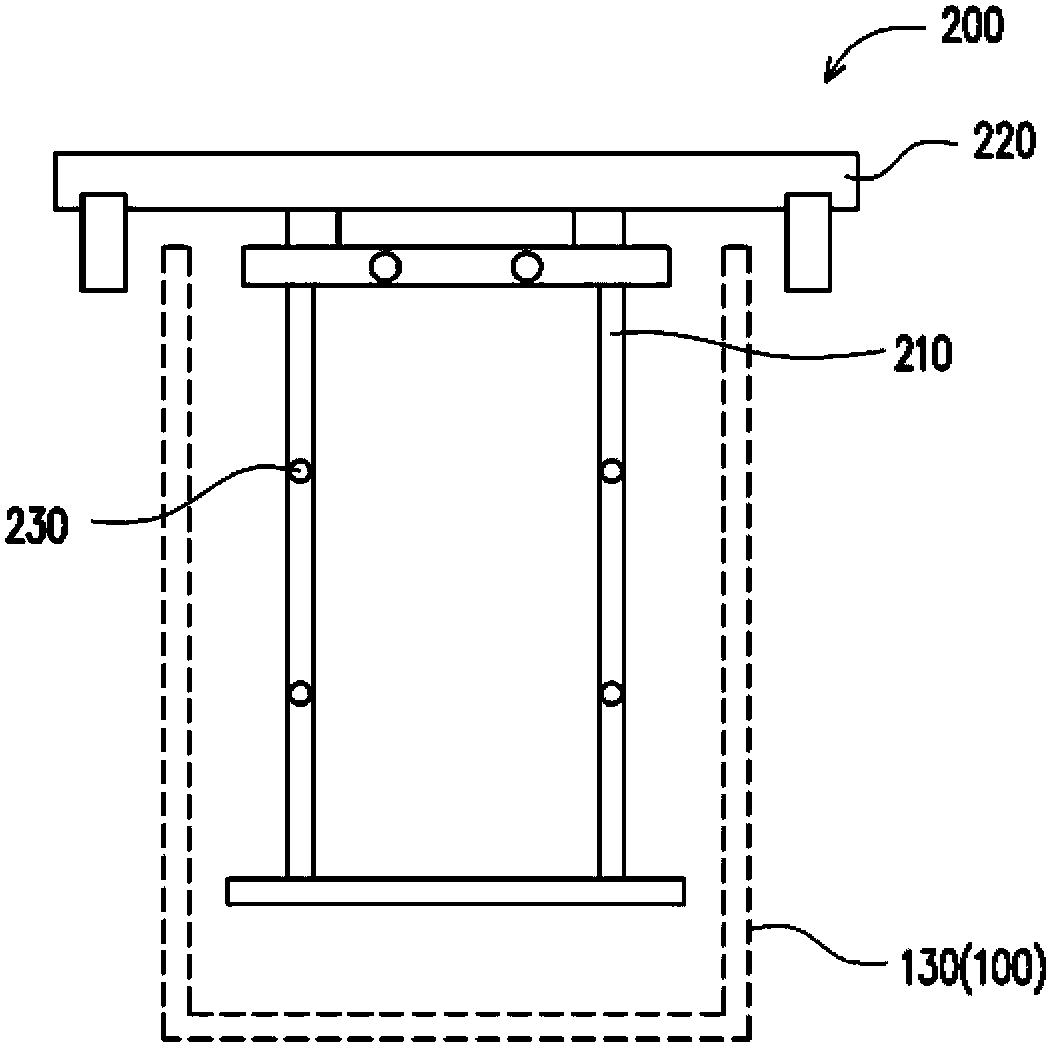

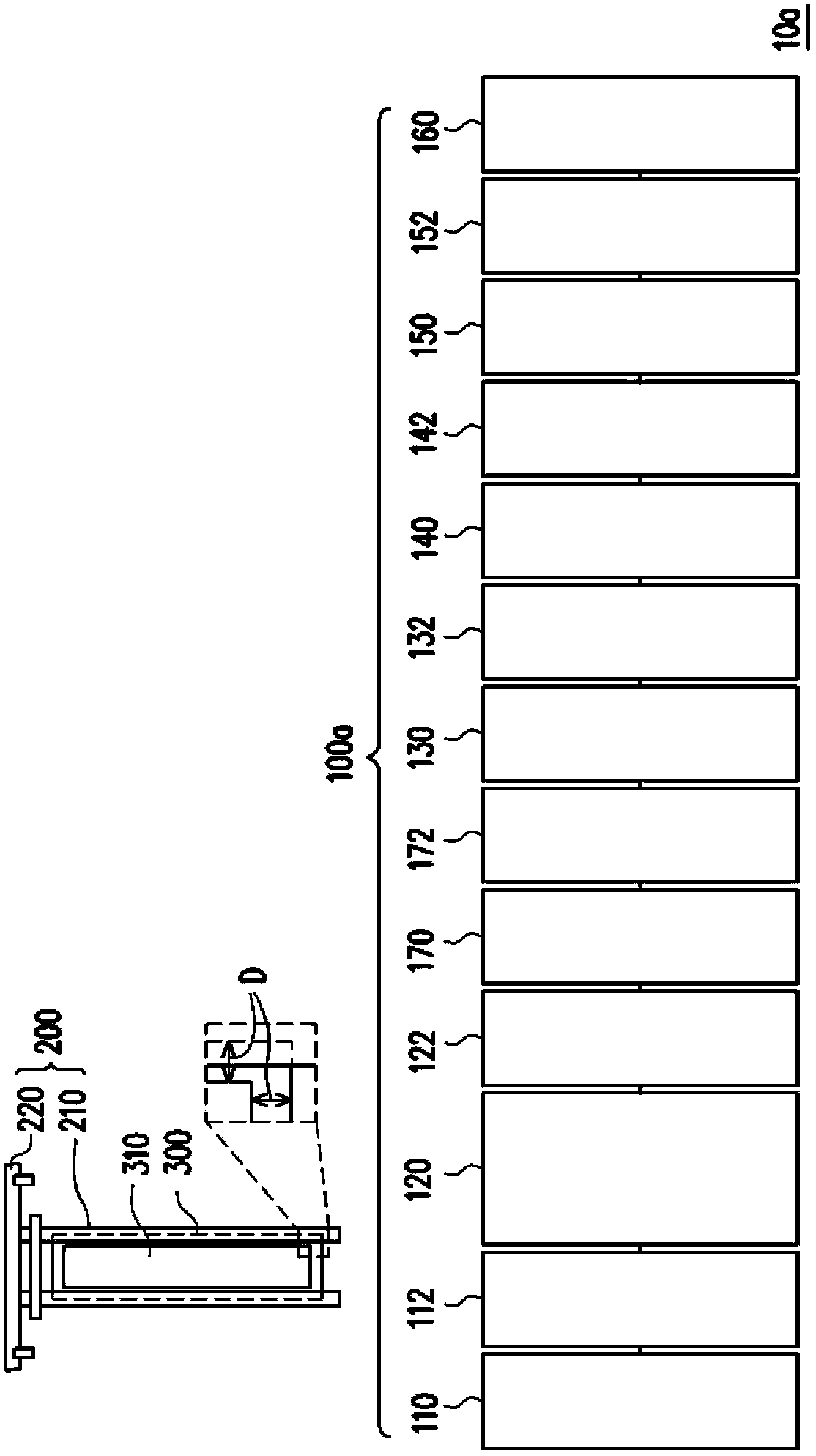

[0045] figure 1 It is a schematic diagram of a circuit board developing, electroplating and etching equipment according to an embodiment of the present invention. figure 2 is a schematic diagram of a mobile unit according to an embodiment of the present invention. Please also refer to figure 1 and figure 2 , in this embodiment, the circuit board developing, electroplating and etching equipment 10 is suitable for developing, electroplating and etching an exposed circuit board 300, wherein the circuit board 300 is, for example, a printed circuit board (Printed Circuit Board, PCB).

[0046] The circuit board developing, electroplating and etching equipment 10 includes a plurality of tank units 100 and a moving unit 200 . Tank unit 100 comprises a developing tank 110, a first washing tank 112, a pickling tank 120, a second washing tank 122, an electroplating tank 130, a third washing tank 132, a stripping tank 140, a fourth washing tank tank 142 , an etching tank 150 , a fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com