Iron-based nano-crystalline soft magnetic alloy and method for manufacturing same

A technology of iron-based nanocrystals and soft magnetic alloys, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of poor soft magnetic properties, large saturation hysteresis coefficient, etc., and achieve high saturation magnetic induction intensity and annealing temperature Guaranteed interval range and reduced technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

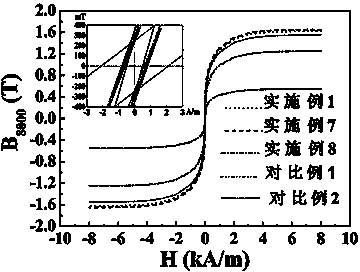

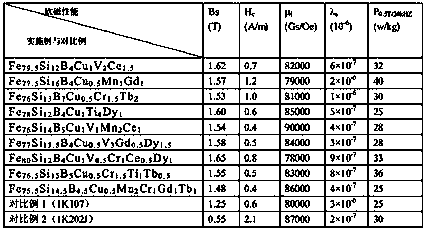

[0018] In this embodiment, the chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 79.5 Si 12 B 4 Cu 1 V 2 Ce 1.5 ;

[0019] 1) Weigh Fe, B-Fe, Si-Fe, Cu, V, Ce with a purity greater than 99.9% according to the composition ratio requirements of each alloy;

[0020] 2) Put the raw materials prepared in step 1 into the electric arc furnace and vacuumize to 5×10 -3 Below Pa, first melt the oxygen-absorbing Ti block to exhaust the oxygen in the residual cavity, then repeatedly smelt each sample 4 to 5 times, and apply electromagnetic stirring during the smelting process to ensure that the components are evenly distributed. Then, break the smelted master alloy, clean it with distilled water and alcohol, then put it into a quartz glass tube, fix the quartz glass tube with the master alloy on the roller, and evacuate to 6×10 -3 Below Pa, fill with argon. The master alloy is heated to a high-temperature molten state by induction, and is sprayed onto a ...

Embodiment 2

[0023] In this embodiment, the chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 77.5 Si 16 B 4 Cu 0.5 mn 1 Gd 1 ;

[0024] 1) Weigh Fe, B-Fe, Si-Fe, Cu, Mn, Gd with a purity greater than 99.9% according to the alloy composition ratio requirements;

[0025] 2) Same as step 2 of embodiment 1;

[0026] 3) Preparation of nanocrystalline soft magnetic alloy by amorphous crystallization annealing method: conduct crystallization annealing on the amorphous strip obtained by rapid quenching under the protection of Ar gas in a vacuum annealing furnace. The annealing temperature is 450°C, and the holding time is 50 minutes. Then cool to room temperature with the furnace.

Embodiment 3

[0028]In this embodiment, the chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 76 Si 13 B 7 Cu 0.5 Cr 1.5 Tb 2 ;

[0029] 1) Weigh Fe, B-Fe, Si-Fe, Cu, Cr, Tb with a purity greater than 99.9% according to the alloy composition ratio requirements;

[0030] 2) Same as step 2 of embodiment 1;

[0031] 3) Preparation of nanocrystalline soft magnetic alloy by amorphous crystallization annealing method: conduct crystallization annealing on the amorphous strip obtained by rapid quenching under the protection of Ar gas in a vacuum annealing furnace. Then cool to room temperature with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com