Composite phenolic building insulation board and manufacturing method thereof

A technology for building thermal insulation and manufacturing methods, which is applied in thermal insulation, building components, chemical instruments and methods, etc., can solve problems such as poor water absorption, long construction period, and blackening of walls, and achieve good bonding ability, simple construction, and The effect of preventing mold and blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

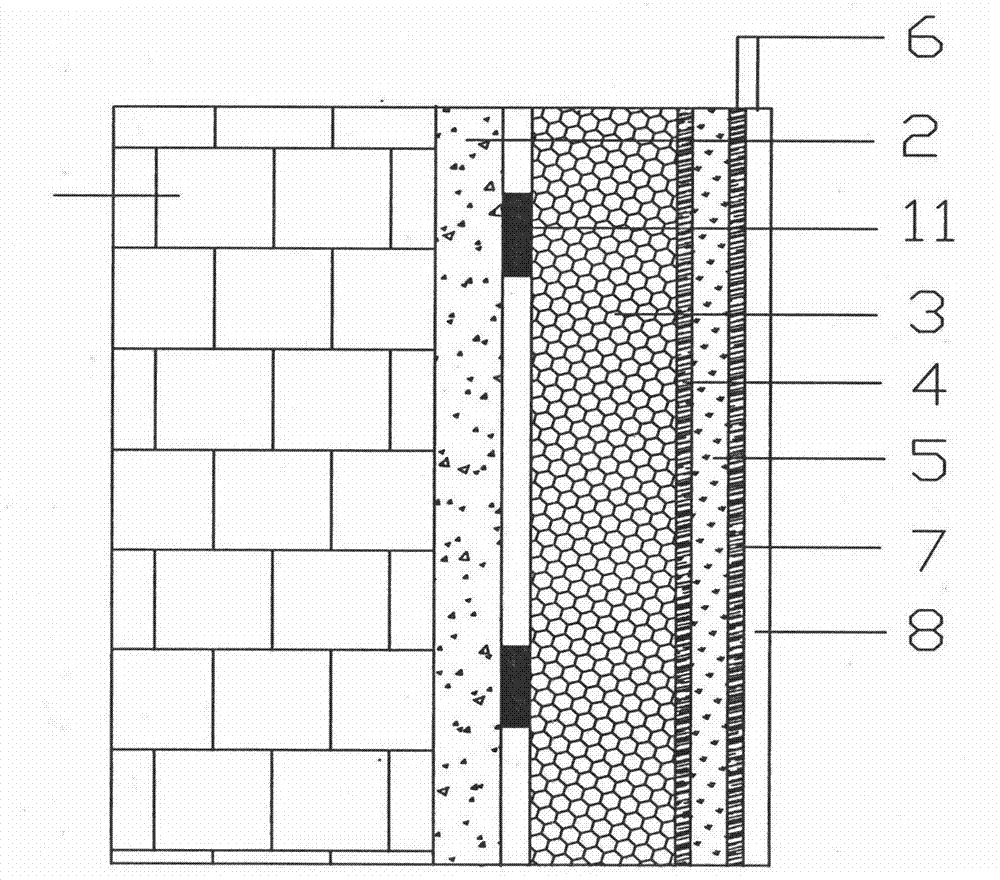

[0022] Embodiment 1, with reference to figure 1 , the present embodiment is a composite phenolic building insulation board with a specification of 1m×2m, including a phenolic foam insulation layer 3, an adhesive layer 4, an inorganic material composite board layer 5, and a protective surface layer 6, and the adhesive layer 4 is located on the phenolic foam Between the insulation layer 3 and the inorganic material composite board layer 5, a protective surface layer is provided on the outer surface of the inorganic material composite board layer 5. The thickness of the phenolic foam insulation layer 3 is 30mm, and the thickness of the bonding layer 4 is 0.2mm. The thickness of the slab 5 is 3mm, and the component weight ratio of the raw material of the phenolic foam insulation layer is: phenolic resin: special surfactant for polyurethane: foaming agent: active toughening agent=100: 1.5: 4: 3, so The bonding layer is a phenolic polyurethane adhesive. The composite sheet layer of...

Embodiment 2

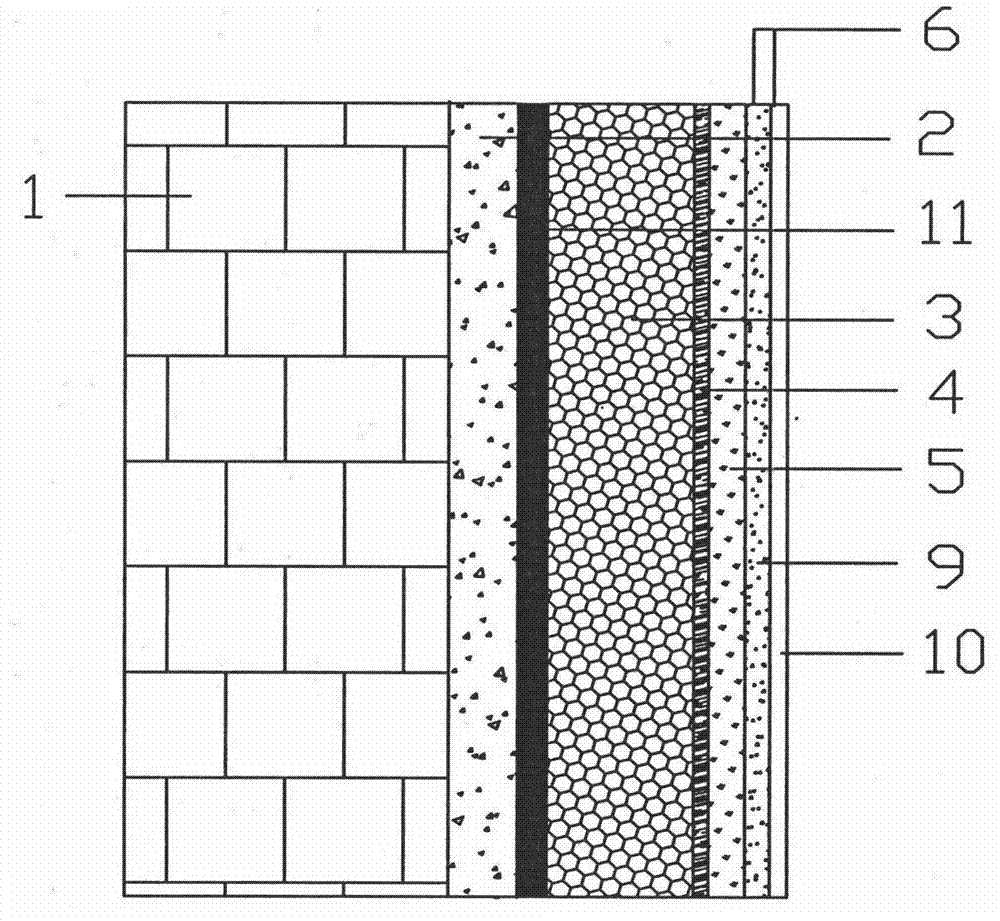

[0029] Embodiment 2. This embodiment is a composite phenolic building insulation board with a specification of 1m×2m, including a phenolic foam insulation layer 3, an adhesive layer 4, an inorganic material composite board layer 5, and a protective surface layer 6. The adhesive layer 4 is set Between the phenolic foam insulation layer 3 and the inorganic material composite board layer 5, a protective surface layer 6 is provided on the outer surface of the inorganic material composite board layer 5, the thickness of the phenolic foam insulation layer 3 is 60mm, and the thickness of the adhesive layer 4 is 0.8mm , the thickness of the inorganic material composite board layer 5 is 7mm, and the component weight ratio of described phenolic foam insulation layer raw material is: phenolic resin: special surfactant for polyurethane: foaming agent: active toughening agent=100: 4: 8 : 13, the bonding layer is a phenolic polyurethane adhesive. The inorganic material composite board layer...

Embodiment 3

[0036] Embodiment 3, the present embodiment is basically the same as Embodiment 2, except that the thickness of the phenolic foam insulation layer 3 is 80mm, the thickness of the bonding layer is 0.6mm, and the thickness of the inorganic material composite board is 9mm. The phenolic foam The weight ratio of the components of the insulation layer raw materials is: phenolic resin: polyurethane special surfactant: foaming agent: active toughening agent = 100:3:6:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com