New high-pressure bubble crushing device

A pulverizing device and high-pressure technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of low cost, insignificant effect, poor oxygen-enhancing effect, etc., and achieve the effect of simple structure, easy manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

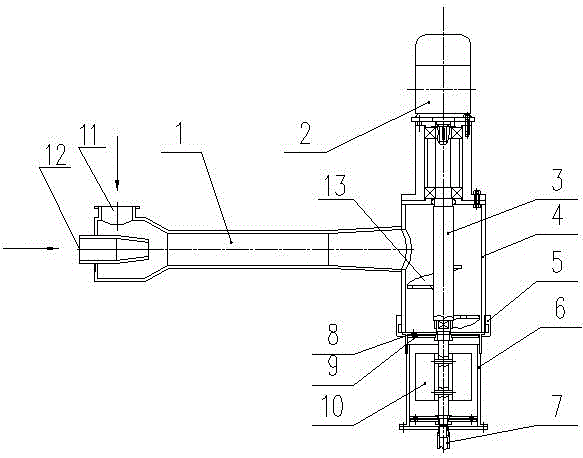

[0025] figure 1 The direction indicated by the middle arrow is the flow direction of the fluid.

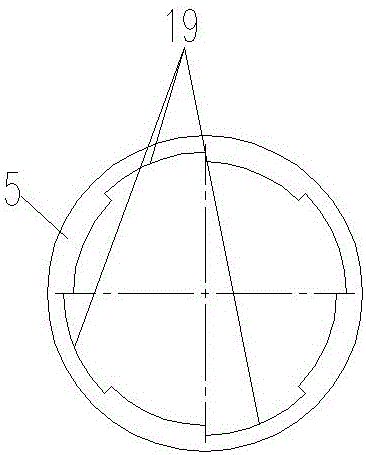

[0026] like Figure 1 to Figure 6 As shown, the novel high-pressure air bubble crushing device of the present invention includes a jet 1, a main cylinder 4, a quick-change snap ring 5 and a cutting device.

[0027] The inlet end of the ejector 1 is provided with an air inlet 11 and a pressure water inlet 12 , and the outlet end of the ejector 1 communicates with the main cylinder 4 .

[0028] The main cylinder 4 is vertically provided with a main shaft 3, and the main shaft 3 is provided with a helical blade 13; the top of the main cylinder 4 is provided with a high-speed motor 2, and the output shaft of the high-speed motor 2 is connected with the coaxial transmission of the main shaft 3; The bottom end of the main cylinder body 4 is provided with a smooth opening, and the bottom end of the main cylinder body 4 is connected to the cutting device.

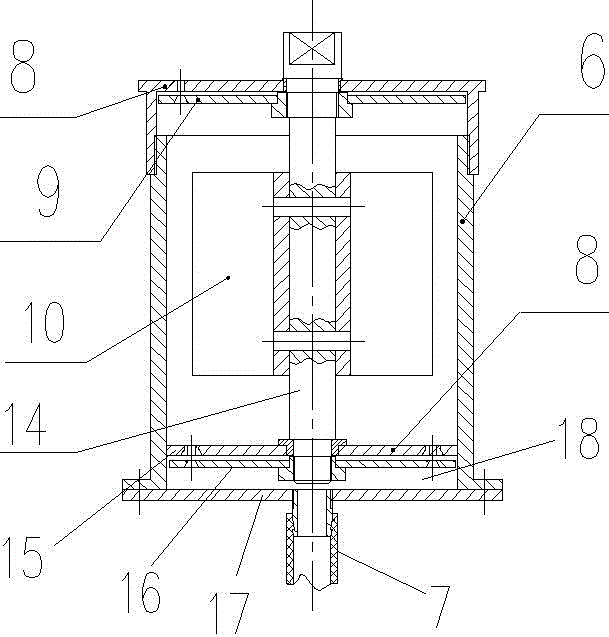

[0029] The cutting device c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com