Edge forming device for loom

A loom and driving device technology, applied in the loom, selvage opening mechanism, textile and other directions, can solve the problems of damage to the driving device, the influence of the driving device becomes larger, and cannot cope with the high speed of the loom, so as to reduce the possibility of damage. Sex, the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

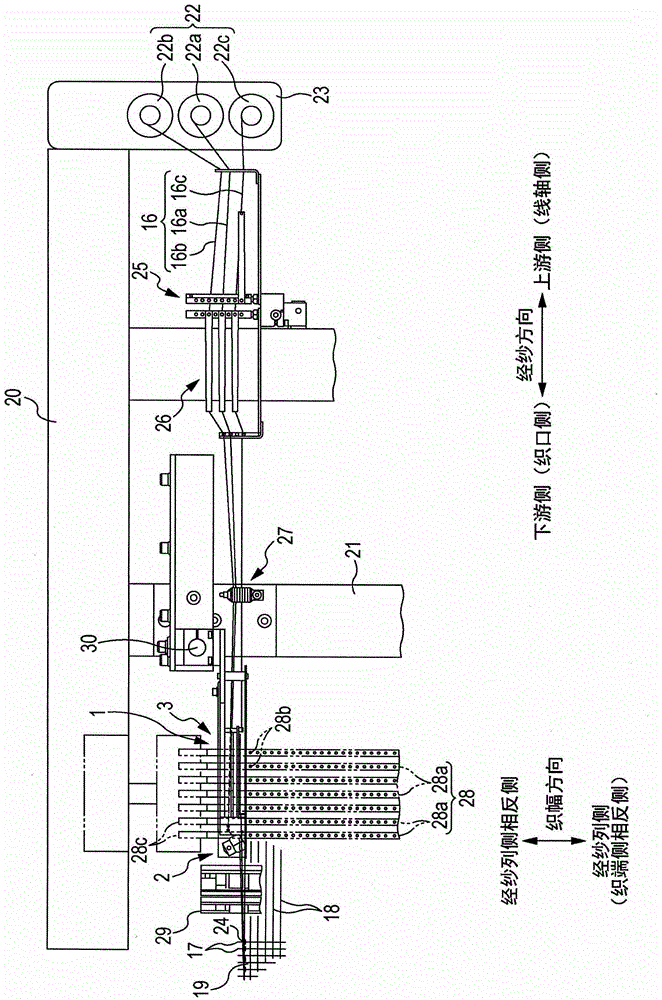

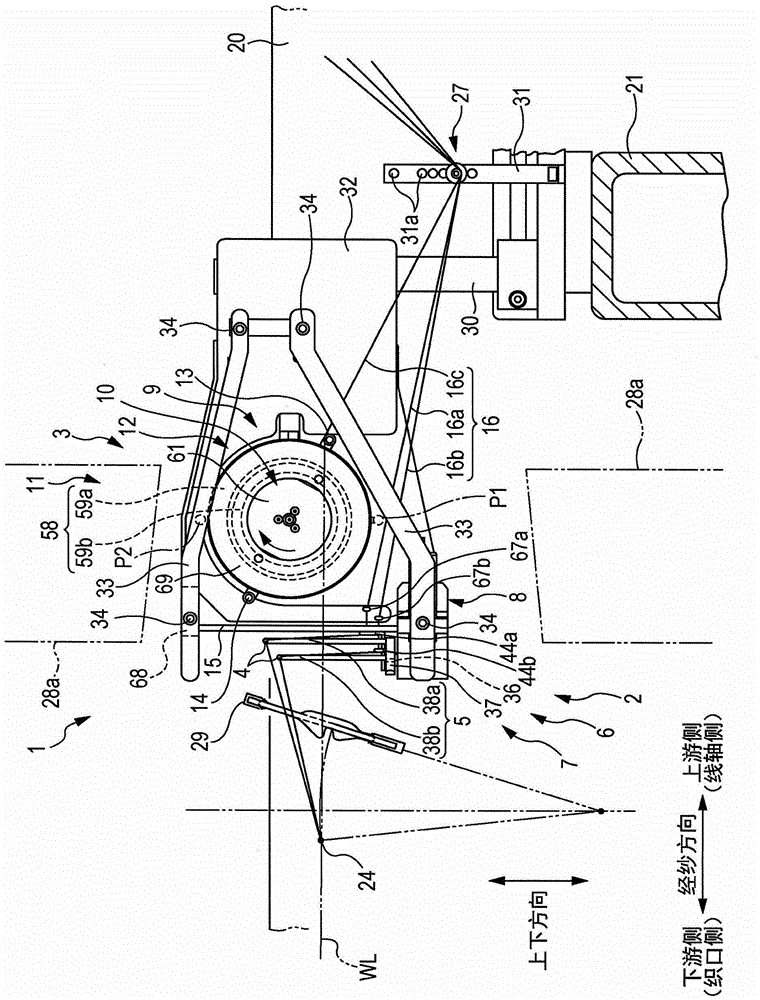

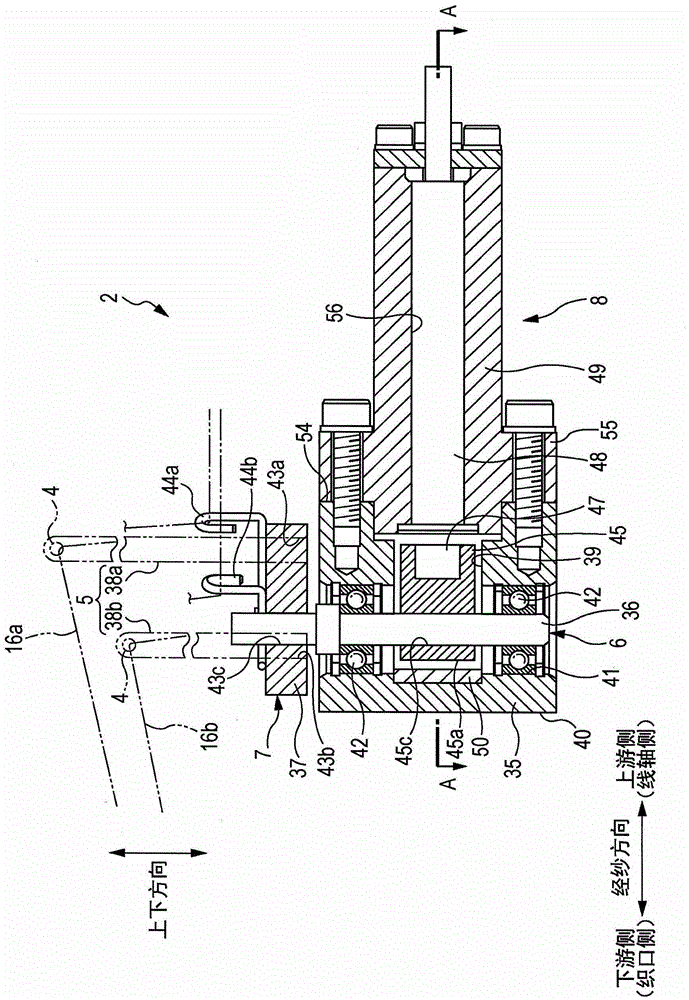

[0231] Below, based on Figure 1 to Figure 9 One embodiment of the edge forming device of the present invention will be described. In the following description, the direction parallel to the traveling direction of the warp yarn 18 is referred to as the "warp yarn direction", and in the warp yarn direction, the side where the warp yarn 18 is supplied to the unshown warp yarn bundle side, that is, the warp yarn delivery side is referred to as the "upstream side". , set the fabric fell side as "downstream side". In addition, the flying direction of the weft yarn 17 is referred to as the "weaving direction", and the weaving direction when the loom is viewed from the downstream side to the upstream side is also referred to as the "left-right direction".

[0232] figure 1 It is a partially enlarged plan view of a loom provided with the edge forming device 1 for the loom of the present invention. In addition, the side forming devices 1 are respectively provided at positions near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com