A copolyester melt ultra-high-speed direct spinning controllable multi-shrinkage composite fiber and its preparation method

A composite fiber and copolyester technology, which is applied in the field of chemical fiber, can solve the problems of uneven color spots and white spots on the surface of the fabric, poor moisture absorption, breathability and moisture retention, and unstable product quality, and achieve easy dyeing, level dyeing, high color rendering and uniformity Non-toxic, moisture-absorbing, moisturizing, breathable, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

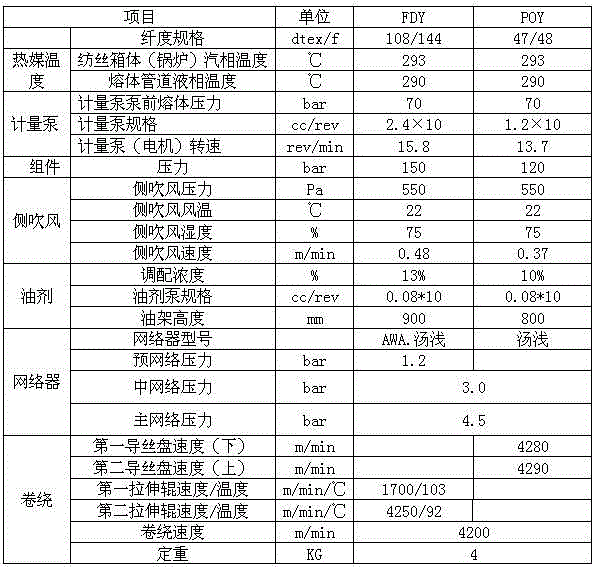

[0024] This example provides a five-component copolyester melt of 155dtex / 192f (in which: the specification of fully drawn yarn is 108dtex / 144f, and the specification of pre-oriented yarn is 47dtex / 48f), which can be prepared by ultra-high-speed spinning and stretching. The production process conditions of multi-control multi-shrinkage composite fibers are as follows:

[0025]Put the mass fraction of 70% terephthalic acid (PTA) and mass fraction of 30% ethylene glycol (EG) as the first and second components, and inject the mixed ingredients into the slurry tank to use terephthalic acid and ethylene glycol The total amount is 100%, add catalyst ethylene glycol antimony 0.04%, additives trimethyl phosphate 0.01%, cobalt acetate 0.011%, sodium acetate 0.005%, mix and stir, and pump into the first esterification kettle through the slurry crank pump Carry out the esterification reaction, and then automatically flow into the second esterification tank through the liquid level differ...

Embodiment 2

[0038] This example provides a 138dtex / 108f (including: fully drawn yarn specification 55dtex / 36f, pre-oriented yarn specification 83dtex / 72f) copolyester melt ultra-high-speed direct spinning to prepare a controllable multi-shrinkage composite fiber. The production process is the same as in Example 1. The mixed ingredients of 70% terephthalic acid (PTA) and 30% ethylene glycol (EG) are injected into the slurry tank, and the catalyst ethylene glycol antimony 0.04% and additives are added. Trimethyl phosphate 0.01%, cobalt acetate 0.011%, sodium acetate 0.005%, mixed and stirred, pumped into the first esterification kettle through the slurry crank pump for esterification reaction, and then automatically flowed into the second esterification kettle through the liquid level difference , and at the same time add the ethylene glycol (EG) solution with a mass fraction of 1.0% of the third component polyethylene glycol, a mass fraction of 0.007% of the fourth component of diethylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com