High-vacuum grease deodorization device

A grease deodorization, high vacuum technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of high trans fatty acid content, dark oil color, high energy waste, etc., to achieve strong production stability, easy operation, saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

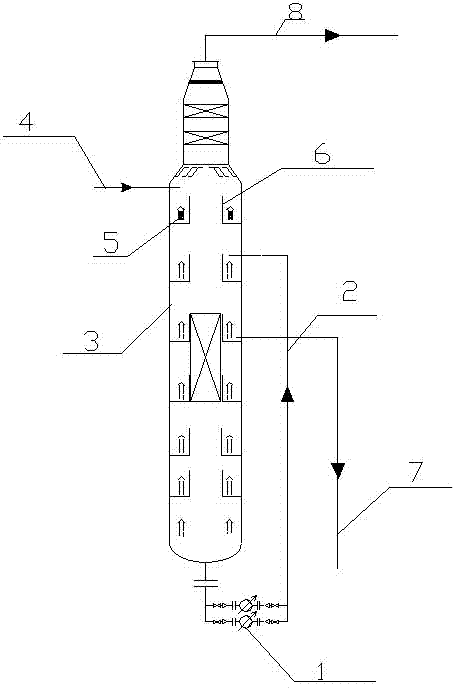

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises device outer casing 3, inner casing 6, oil return pipe 2 and a plurality of heater groups 5 that are arranged in reactor inner casing 6, and heater 5 is arranged on device from top to bottom. At the center of the casing 6, a plurality of circular heater groups 5 are uniformly arranged in a circle around the inner casing 6, the upper end of the inner casing 6 is provided with an oil inlet pipe 4, and the upper end of the device casing is provided with an oil outlet pipe 7.

[0010] The inner casing 6 and the outer casing 3 of the device are circular, and there is an oil return pipe 2 inside the casing, and the motor 1 is connected to the lower end of the oil return pipe 2. Crude oil enters the inner casing 6 of the device through the oil inlet pipe 4, and under the action of the heater 5, Enter the outer casing 3 through the oil return pipe 2 to exchange heat with the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com