Nano water-based fluorocarbon insulated elastic exterior wall paint and preparation method thereof

A water-based fluorocarbon and elastic exterior wall technology, applied in the field of exterior wall latex paint, can solve the problems of poor stain resistance, easy cracking of heat insulation coatings, and no elasticity, etc., to achieve good oil repellency, less susceptible to stains, and low surface freedom Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

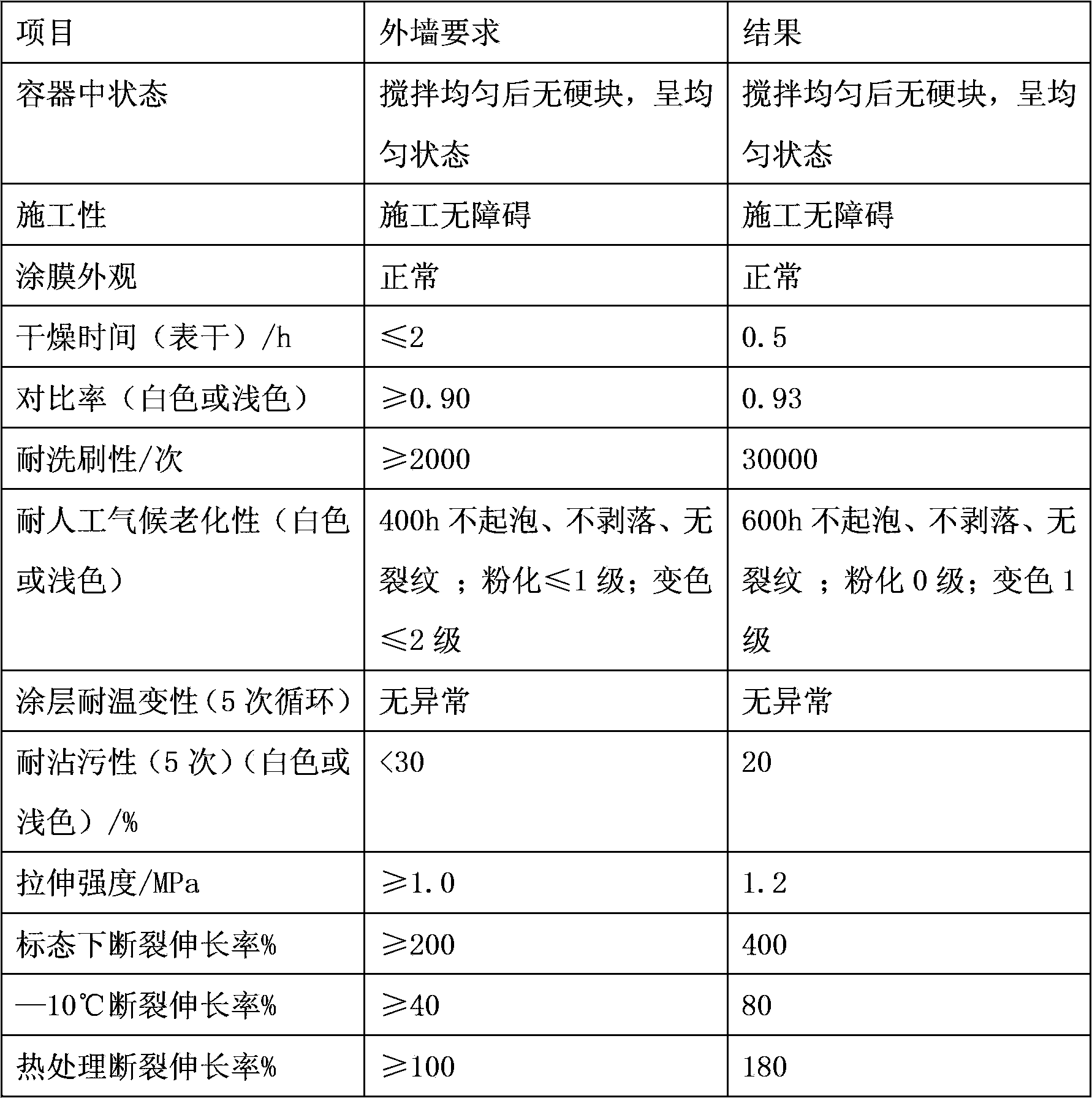

Examples

Embodiment 1

[0047] Add 115 kg of water into the dispersing tank, start stirring at a speed of 400 rpm, add 15 kg of antifreeze, 7 kg of dispersant, 3 kg of wetting agent, 15 kg of film-forming agent, and 2 kg of defoamer while stirring , 3 kg of antifungal agent, 1.5 kg of fungicide, and stir for 5 to 10 minutes. Rotate at a medium speed of 800 rpm, add 23.5 kg of nano-ATO powder, 200 kg of titanium dioxide, 40 kg of calcined kaolin, 60 kg of calcium carbonate, and 20 kg of nano-zirconia dispersion, wet 2 kg of cellulose with 15 kg of water, and then add the above dispersion In the jar, then add 1 kg of pH adjuster, wash the sides of the jar with 15 kg of water, turn it to a high speed of 1500 rpm, and disperse for 30 minutes. Turn at a medium speed of 800 rpm, add 300 kg of self-crosslinking elastic emulsion, 100 kg of fluorocarbon emulsion, 20 kg of masking emulsion, and 3 kg of defoamer while stirring, and stir for 10 minutes. Rotate at a low speed of 600 rpm, add 30 kg of hollow glas...

Embodiment 2

[0049] Add 104 kg of water into the dispersing tank, start stirring at a speed of 400 rpm, add 15 kg of antifreeze, 7 kg of dispersant, 3 kg of wetting agent, 15 kg of film-forming agent, and 2 kg of defoamer while stirring , 3 kg of antifungal agent, 1.5 kg of fungicide, and stir for 5 to 10 minutes. Turn at a medium speed of 800 rpm, add 20 kg of nano-ATO powder, 180 kg of titanium dioxide, 60 kg of calcined kaolin, 80 kg of calcium carbonate, and 30 kg of nano-zirconia dispersion liquid, wet 1 kg of cellulose with 15 kg of water, and then add the above dispersion In the jar, then add 1 kg of pH adjuster, wash the sides of the jar with 15 kg of water, turn it to a high speed of 1500 rpm, and disperse for 30 minutes. Rotate at a medium speed of 800 rpm, add 250 kg of self-crosslinking elastic emulsion, 120 kg of fluorocarbon emulsion, 30 kg of masking emulsion, and 3 kg of defoamer while stirring, and stir for 10 minutes. Rotate at a low speed of 600 rpm, add 40 kg of hollow...

Embodiment 3

[0051] Add 111 kg of water into the dispersing tank, start stirring at a speed of 400 rpm, add 15 kg of antifreeze, 7 kg of dispersant, 3 kg of wetting agent, 15 kg of film-forming agent, and 2 kg of defoamer while stirring , 3 kg of antifungal agent, 1.5 kg of fungicide, and stir for 5 to 10 minutes. Turn at a medium speed of 800 rpm, add 50 kg of nano-ATO powder, 220 kg of titanium dioxide, 20 kg of calcined kaolin, 40 kg of calcium carbonate, and 10 kg of nano-zirconia dispersion liquid, wet 3 kg of cellulose with 15 kg of water, and then add the above dispersion In the jar, then add 1 kg of pH adjuster, wash the sides of the jar with 15 kg of water, turn it to a high speed of 1500 rpm, and disperse for 30 minutes. Turn at a medium speed of 800 rpm, add 350 kg of self-crosslinking elastic emulsion, 80 kg of fluorocarbon emulsion, 10 kg of masking emulsion, and 3 kg of defoamer while stirring, and stir for 10 minutes. Rotate at a low speed of 600 rpm, add 20 kg of hollow gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com