Water spray discharge air plasma jet processing device and high-voltage power source thereof

A plasma and treatment device technology, applied in the field of wastewater treatment, can solve the problems of inability to automatically adjust, high operating costs, high energy consumption, etc., achieve good application prospects, and improve the effect of chemical reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

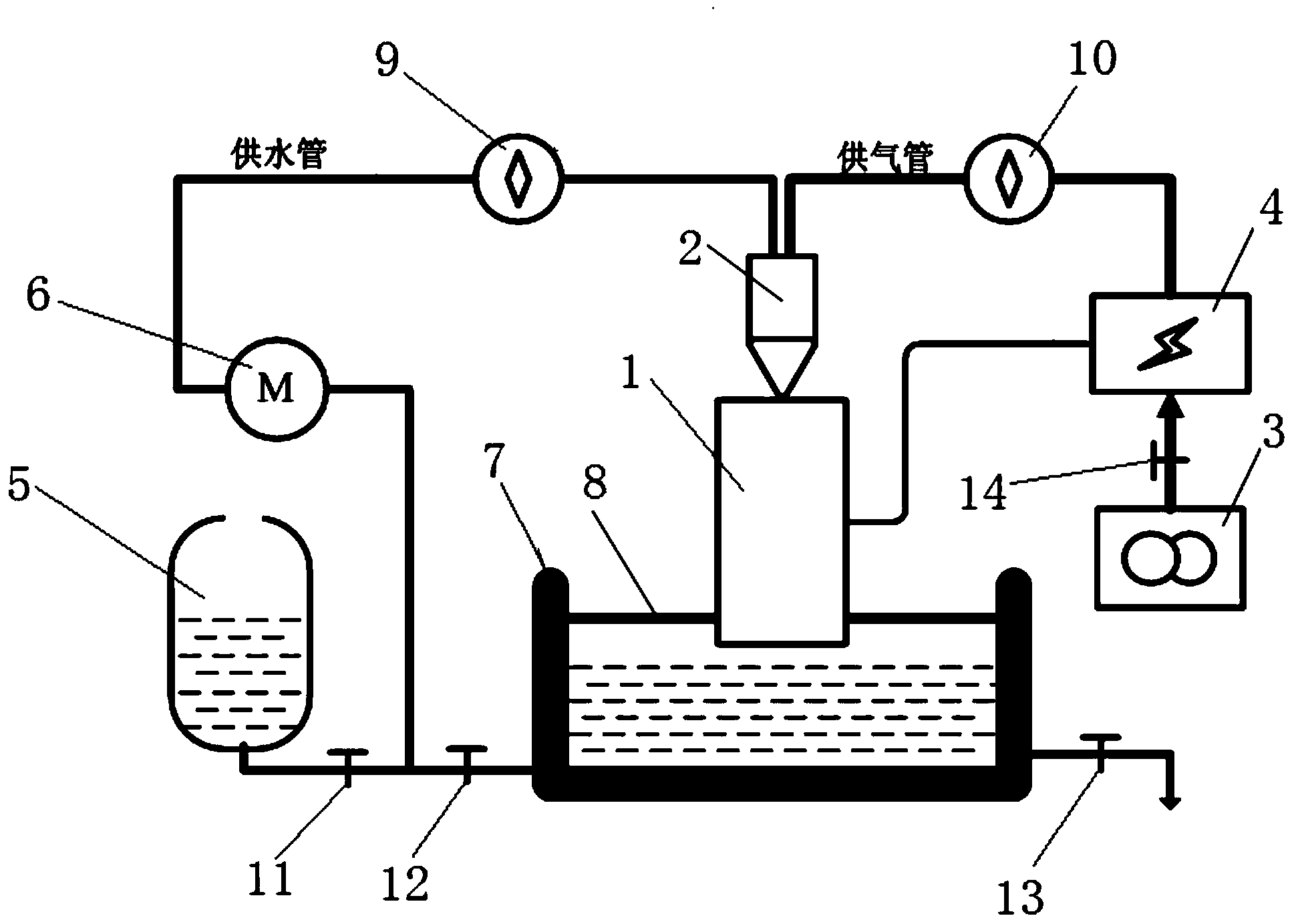

Embodiment 1

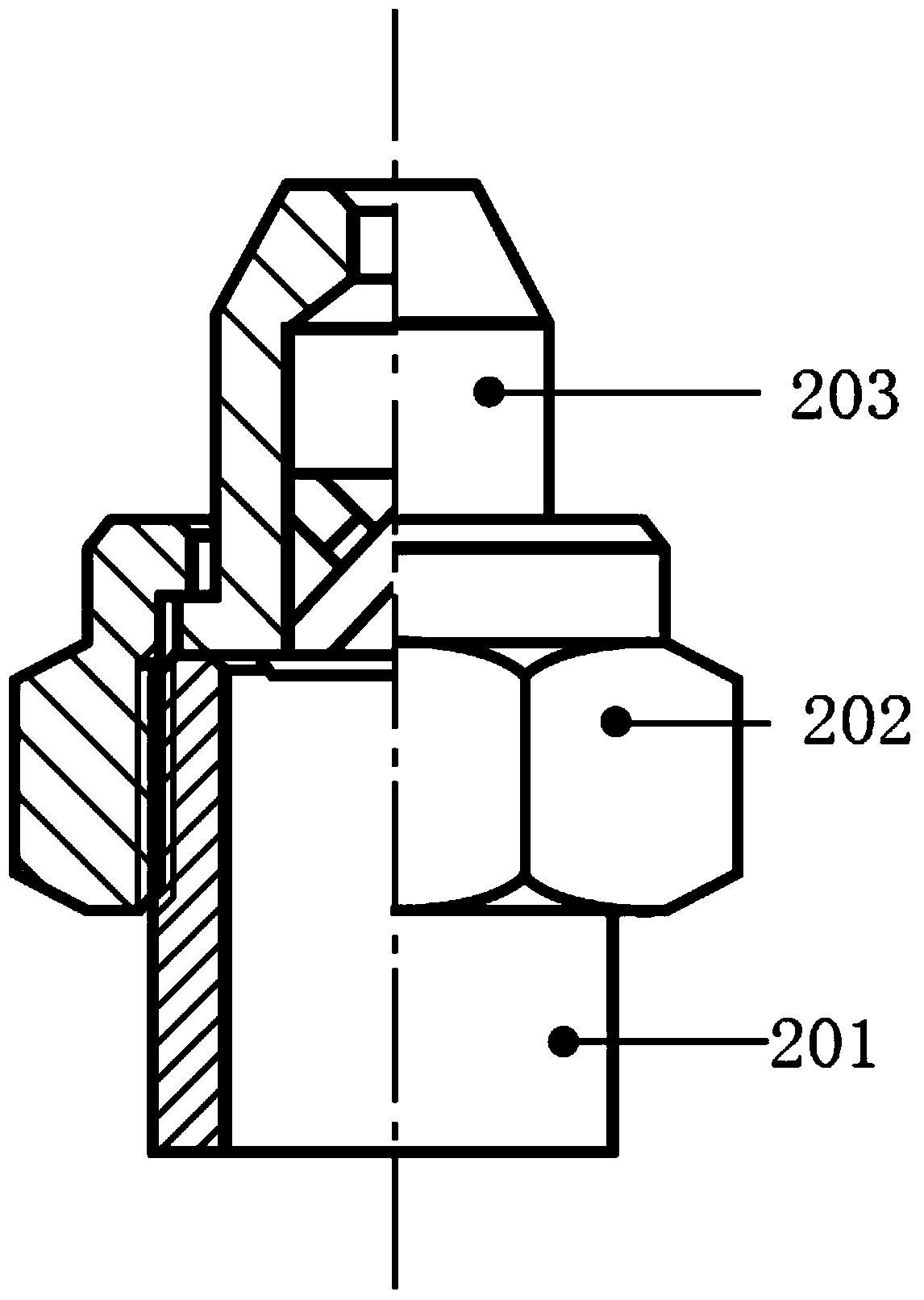

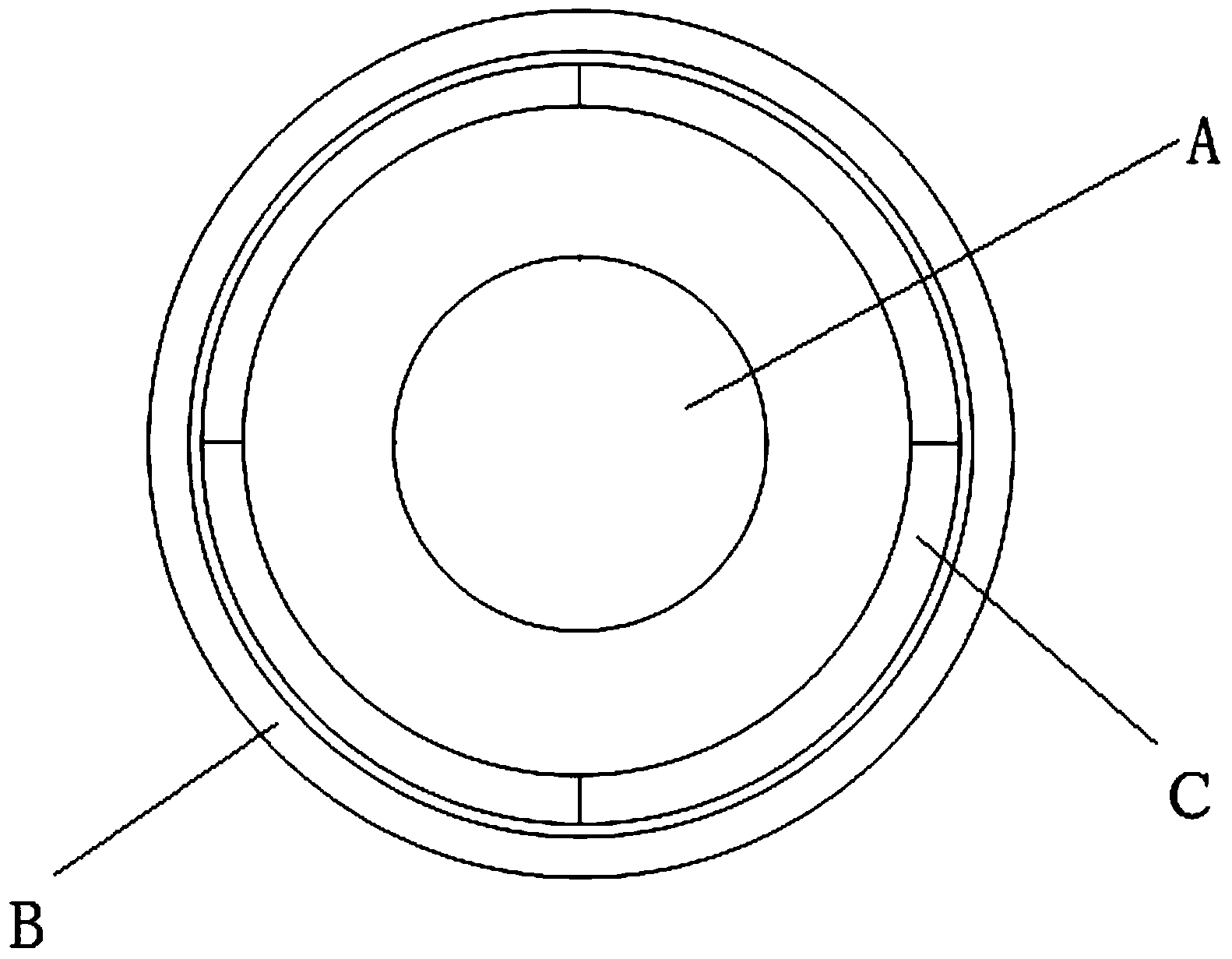

[0034] Such as figure 2 As shown, the atomizing nozzle 2 includes a nozzle base 201, a fixed nut 202 and a nozzle 203, the nozzle 203 is installed on the nozzle base 201 through the fixed nut 202, and the nozzle 203 is a conical nozzle; image 3 As shown, the water mist jet discharge reactor 1 is a cylindrical water mist jet discharge reactor, including an outer electrode B made of cylindrical stainless steel, an electrode A located in the cavity of the outer electrode B, and an electrode B located in the outer electrode B. There is a layer of quartz glass tube body C on the inner wall, and the inner electrode A is composed of two stainless steel balls with different diameters and a stainless steel rod-shaped material. The large-diameter stainless steel ball is at the top, and the small-diameter stainless steel ball is at the bottom. welded together.

Embodiment 2

[0036] Such as Figure 4 As shown, the atomizing nozzle 2 includes a nozzle base 201, a fixed nut 202 and a nozzle 203, the nozzle 203 is installed on the nozzle base 201 through the fixed nut 202, and the nozzle 203 is a fan-shaped nozzle; Figure 5 As shown, the water mist jet discharge reactor 1 is a fan-shaped plate-shaped water mist jet discharge reactor, including a plate-shaped electrode B, an electrode A with a raised arc, and a layer of quartz glass on one side of the electrode B Plate body C, the electrode A with a convex arc is located above the quartz glass plate body C.

[0037] The minimum discharge distance d between the discharge electrodes of the water mist jet discharge reactor 1 and the breakdown voltage V B follow Paschen's law, namely:

[0038] V B = Bpd ln ( Apd ln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com