Application of trimethylene sulfide serving as hydrate accelerant

A technology of hydrate accelerator and trimethethylenesulfur, which is applied in the direction of sulfur compounds, carbon compounds, hydrocarbons, etc., can solve the problems of slow reaction rate, difficult treatment of waste liquid, and harsh conditions for hydrate formation, so as to improve hydration The formation temperature of gas hydrates and the effect of promoting the formation of gas hydrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

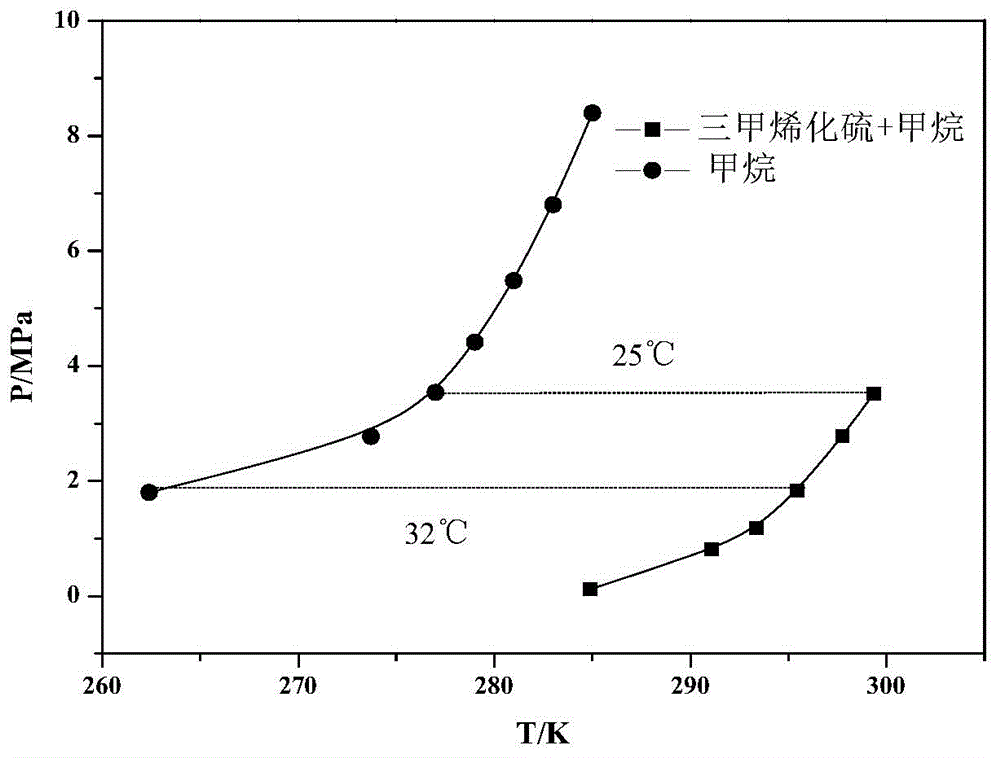

Embodiment 1

[0016] Vacuum the inside of the reactor, inject 20ml of trimethethylenesulfur and 135mL of deionized water into the reactor (about 1 / 2 of the viewing window), feed methane gas up to 0.01-5.0MPa, turn on the reactor and stir at 600-800rpm, Turn on the refrigeration cycle, cool down the system and observe until hydrate solids are formed in the reactor. The temperature of the system is gradually raised at a rate of 0.1K each time until there is a trace of hydrate in the reactor. Record the temperature and pressure at this time as the equilibrium temperature and pressure of the hydrate formation phase. When the temperature is 285.90, 291.10, 293.35, 295.45, 297.76, 299.35K, the phase equilibrium pressures are 0.12, 0.81, 1.18, 1.83, 2.78, 3.52MPa respectively. In the same way, the determination of CH 4 The phase equilibrium condition of hydrate is that when the temperature is 275.00, 277.00, 279.00, 281.00, 283.00, 285.00K, its equilibrium pressure is 2.82, 3.54, 4.41, 5.48, 6.8...

Embodiment 2

[0018] Inject trimethethylenesulfur / water with a volume fraction of 7.4% into the reactor, and feed the coal bed gas (CH 4 (0.25) / N 2 (0.70) / O 2 hydrate, CH 4 than N 2 , O 2 It is easy to form hydrates, so as to achieve the enrichment of CH in the hydrate phase 4 the goal of. Decomposition of the hydrate phase yields concentrated CH 4 Mixed gas, and then continue to pass the mixed gas into the reactor, and circulate the previous generation step for secondary enrichment and third enrichment, decompose the hydrate phase, and obtain CH 4 The concentration is as high as 72%.

Embodiment 3

[0020] Inject trimethethylenesulfur / water with a volume fraction of 10% into the reactor, and introduce 17.0% CO 2 flue gas (CO 2 (0.17) / N 2 (0.8215) / SO 2 (0.085)) or IGCC synthesis gas (H 2 (0.61) / CO 2 (0.39)), gas separation is carried out at 5-30°C and 0.01-5MPa. easily hydrated CO 2 into the hydrate phase, thereby forming a CO-rich 2 The gas hydrate slurry phase and N-rich 2 or H 2 the residual gaseous phase. The high concentration of N 2 or H 2 It is extracted under constant pressure as a separated product. will be rich in CO 2 The hydrate slurry phase is pumped into the hydrate decomposition tank for decomposition to obtain a high concentration of CO 2 mixed gas. Then the mixed gas continues to be passed into the reactor, and the previous generation step is circulated to carry out secondary enrichment and third enrichment, decompose the hydrate phase, and the obtained CO 2 The concentration is as high as 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com