Selective high-molecular fracture catalyst as well as preparation method and application thereof

A catalyst and polymer technology, applied in the field of polymer chemistry, can solve problems such as application difficulties, reduced ability to release oxygen, and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

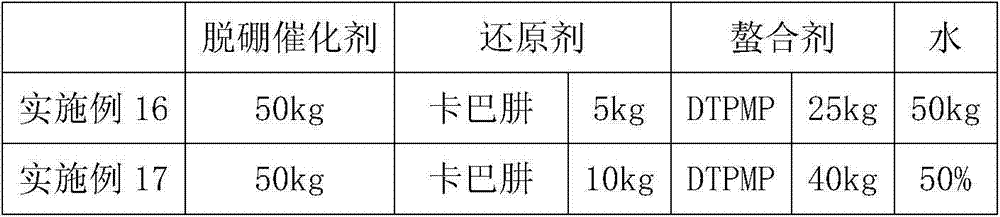

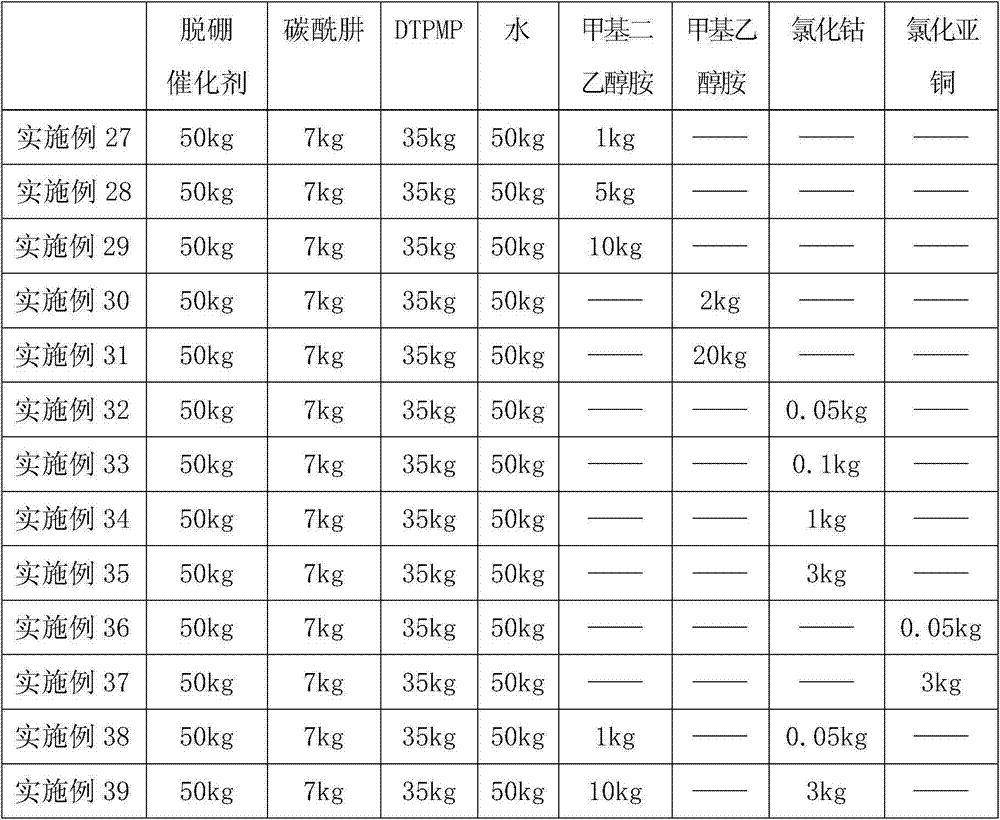

[0026] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0027] 1. Preparation of deboronation catalyst

[0028] 1. Raw material preparation:

[0029]

N-methylglucamine

water

group 1

5kg

20kg

5kg

30kg

group 2

50kg

35kg

20kg

50kg

group 3

75kg

45kg

35kg

65kg

[0030] 2. Preparation method:

[0031] First, add water to the reactor, raise the temperature to 60°C, and control fracturing at 0.1-0.3MPa;

[0032] Then, start the agitator, slowly add N-methylglucamine and benzoic acid into the reactor, and react for 1h;

[0033] Next, raise the temperature of the reactor to 65°C;

[0034] Finally, add triethanolamine, condense to control the water temperature at 65°C, and react for 2 hours to obtain the deboronation catalyst.

[0035] The deboronation catalyst synthesized by N-methylglucamine, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com