Preparation method of titanium dioxide/graphene composite material

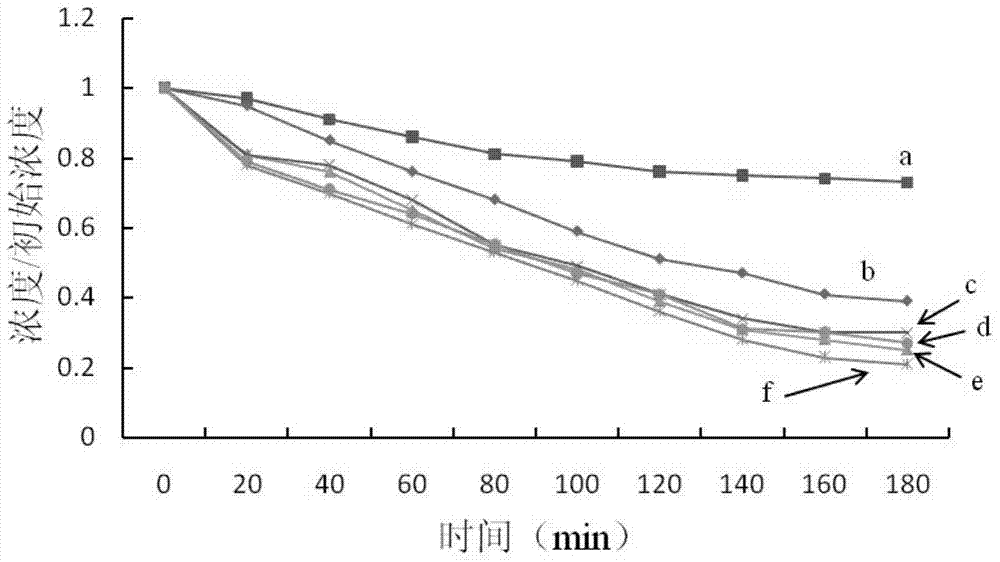

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, nanotechnology for materials and surface science, chemical/physical processes, etc., can solve the problems of low photocatalytic efficiency and large particle size of titanium dioxide, and achieve photocatalytic High efficiency, reduced recombination rate, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 0.5g of colloidal graphite (with a particle size of 0.5-1μm) and 10g of benzoyl peroxide thoroughly and grind them evenly. Heat the mixed powder in a steel explosion-proof container at 110°C for 10 minutes. After the reaction, cool naturally to room temperature, add 100mL of water, ultrasonicate for 1 hour, add 5mL of ascorbic acid aqueous solution (25% by mass) and 15mL of titanium An aqueous tetrabutyl ester solution (mass fraction of 7%) was reacted in a hydrothermal reactor at 160°C for 5 hours. After the hydrothermal reaction, centrifuge, wash with water and isopropanol in sequence, and dry at 80° C. for 10 hours to obtain a relatively pure titanium dioxide / graphene composite material.

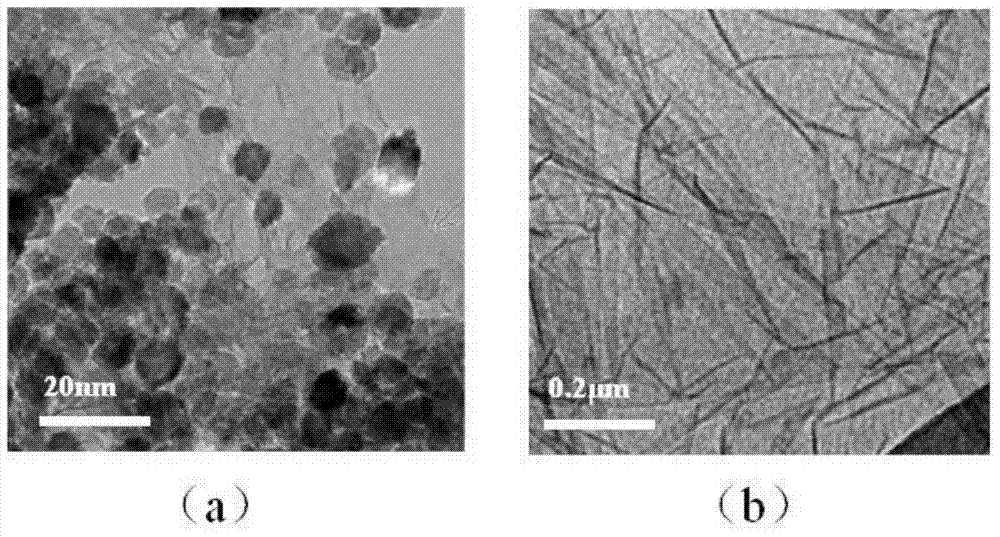

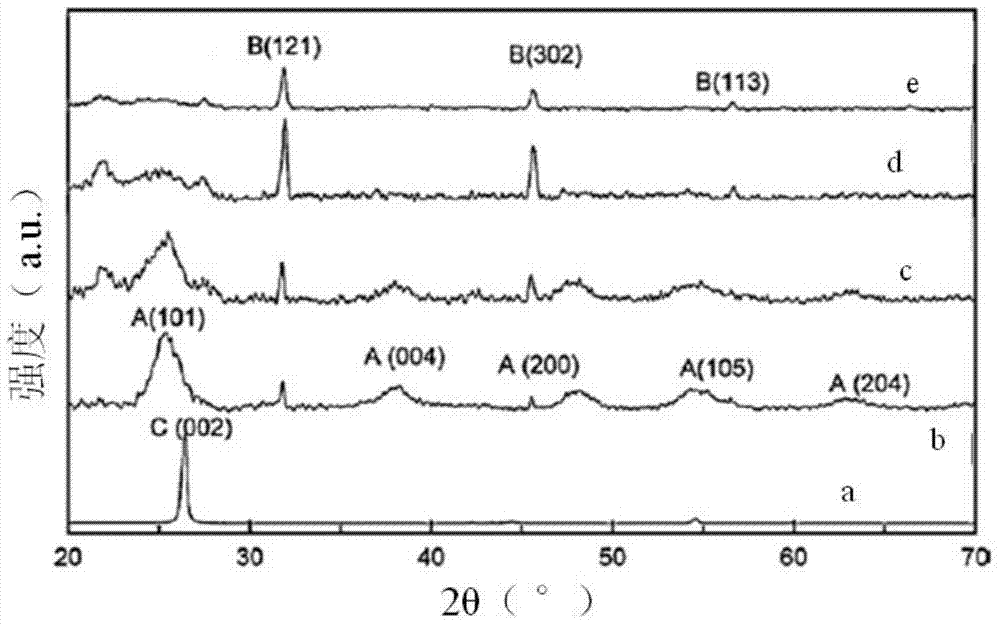

[0031] figure 1 TEM photographs of the titanium dioxide / graphene composite material (a) prepared in Example 1 and the reference product graphite oxide (b). from figure 1 In (a), it can be seen that the surface of graphene is covered with dense and uniformly dispersed TiO 2 ...

Embodiment 2

[0033] Mix 0.5g of colloidal graphite (0.1-1μm in particle size) and 9g of tert-butyl hydroperoxide thoroughly and grind them evenly. Heat the mixed powder in a steel explosion-proof container at 120°C for 20 minutes. After the reaction, cool down to room temperature naturally, add 100mL of water, ultrasonicate for 1.5 hours, and add 5mL of diethylene glycol diacrylate aqueous solution with stirring (mass fraction 30%) and 20mL isopropyl titanate aqueous solution (mass fraction 8%) were reacted in a hydrothermal reactor at 190°C for 4 hours. After the hydrothermal reaction, centrifuge, wash with water and isopropanol in sequence, and dry at 90° C. for 10 hours to obtain a relatively pure titanium dioxide / graphene composite material.

[0034] The TEM photograph of the composite material that the present embodiment makes is similar to embodiment 1, and its TiO 2 The average particle size of the particles is about 15nm.

Embodiment 3

[0036] Mix 0.5g of natural flake graphite and 10g of benzoyl peroxide thoroughly and grind them evenly. Heat the mixed powder in a steel explosion-proof container at 120°C for 25 minutes. After the reaction, cool naturally to room temperature, add 100mL of water, ultrasonicate for 1 hour, add 5mL of hydrazine hydrate aqueous solution (20% by mass) and 15mL of Tetrabutyl titanate aqueous solution (mass fraction: 7%) was reacted in a hydrothermal reactor at 180°C for 5 hours. After the hydrothermal reaction, centrifuge, wash with water and isopropanol in sequence, and dry at 80° C. for 10 hours to obtain a relatively pure titanium dioxide / graphene composite material.

[0037] The TEM photograph of the composite material that the present embodiment makes is similar to embodiment 1, and its TiO 2 The average particle size of the particles is about 5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com