Method for producing polycarbonate resin, polycarbonate resin, polycarbonate resin film-forming method, and method for producing polycarbonate resin pellets

A technology of polycarbonate resin and manufacturing method, which is applied in the field of polycarbonate resin, can solve problems such as increased pressure loss, filter damage, and resin deterioration, and achieve the effects of less foreign matter, excellent mechanical strength, and excellent hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

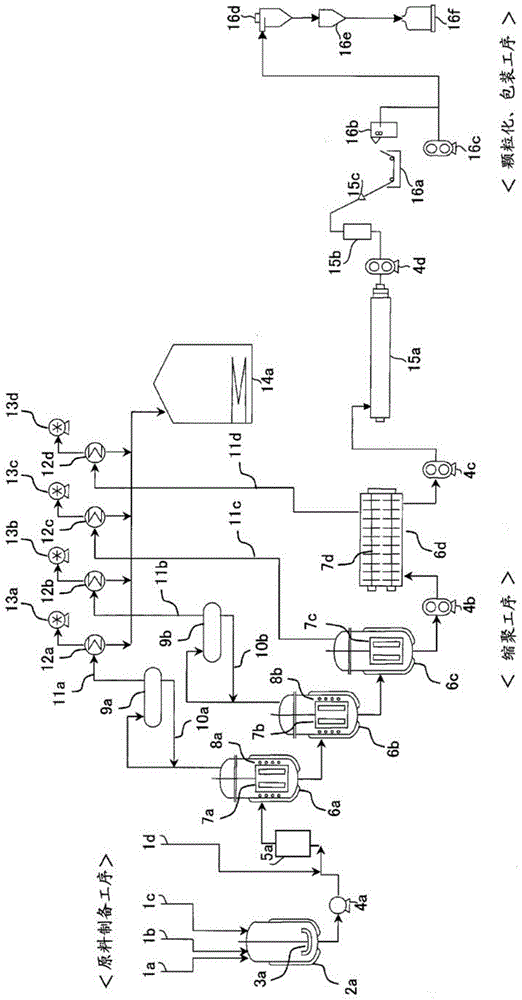

Method used

Image

Examples

Embodiment 1

[0377] (Phase 1 Response)

[0378]The molar ratio of ISB / TCDDM / DPC is 70 / 30 / 100 in a polymerization reactor equipped with a heat medium jacket and stirring paddle with oil as a heat medium, a distillation pipe connected with a vacuum pump, and a condenser, and then added Make the cesium carbonate of aqueous solution, make every 1 mol reach 2.5×10 relative to all dihydroxy compounds -6 mol (converted into cesium metal atoms), and then sufficient nitrogen substitution (oxygen concentration 0.0005% by volume to 0.001% by volume) was carried out. At this time, the DPC used was distilled and purified so that the concentration of chloride ions was 10 ppb or less. Next, the heated heat medium is circulated through the heat medium jacket of the reactor, and stirring is started when the reaction solution (i.e., the internal temperature) reaches 100° C., and the internal temperature is kept at 100° C. to melt the contents and reach 100° C. uniform.

[0379] Thereafter, the temperatur...

Embodiment 2

[0394] It operated similarly to Example 1 except having made the resin supply rate to an extruder 15 kg / h, and having made the screw rotation speed 130 rpm. The temperature of the polycarbonate resin discharged from the die was 264° C., the reduced viscosity was 0.334, the YI of the pellets was 63.2, the phenol content was 476 ppm, and the DPC content was 27 ppm.

Embodiment 3

[0396] It carried out similarly to Example 1 except having set the resin supply rate to an extruder to 20 kg / h, and the screw rotation speed to 150 rpm. The temperature of the polycarbonate resin discharged from the die was 269° C., the reduced viscosity was 0.328, the YI of the pellets was 65.6, the phenol content was 482 ppm, and the DPC content was 29 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com