Assembled slab, method for manufacturing same, and method for manufacturing clad steel material

A manufacturing method and slab technology, which are applied in the fields of assembling slabs and their manufacturing and composite steel manufacturing, can solve problems such as cracking, and achieve the effect of efficient and stable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

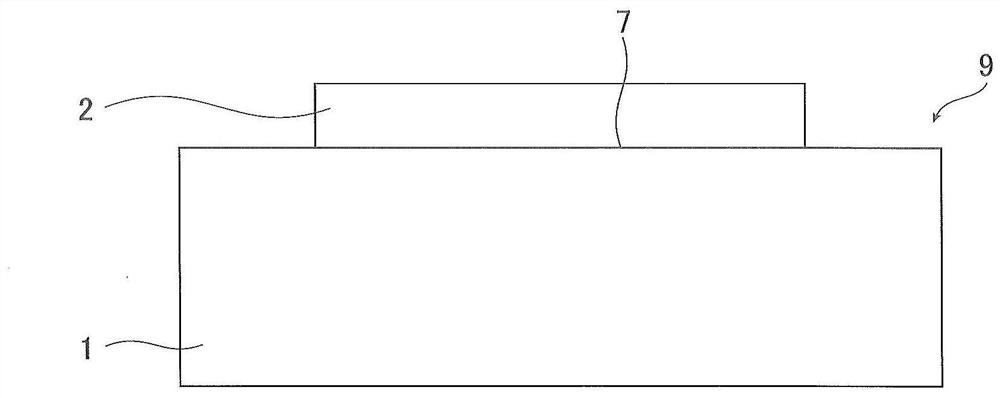

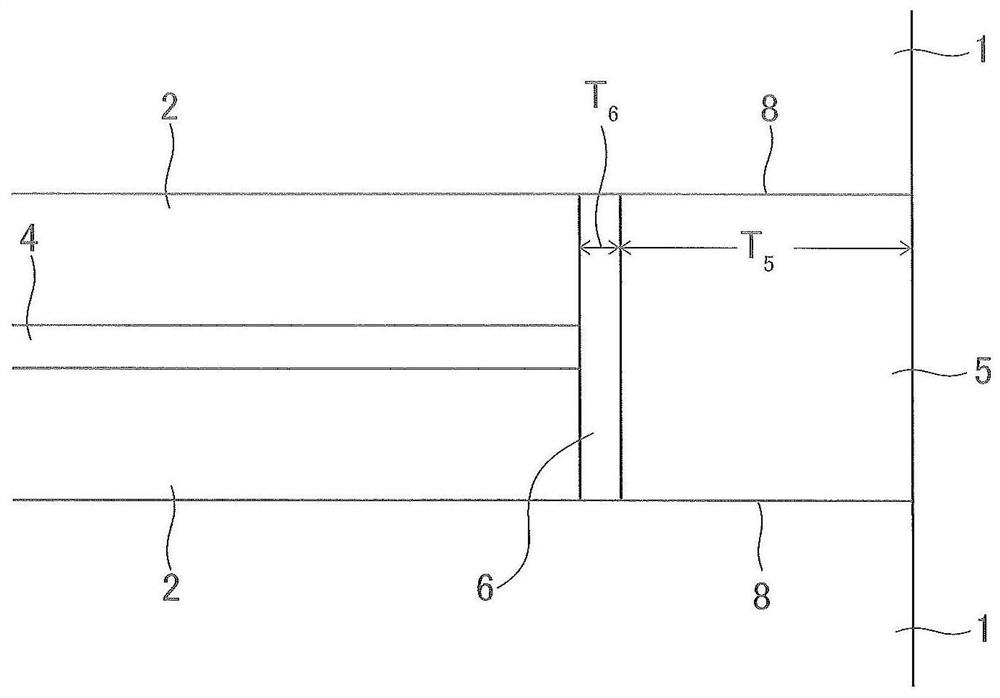

[0060] As Invention Example 1, two base materials equivalent to SM400 (thickness 100 mm x width 1250 mm x length 2000 mm), two joint materials equivalent to SUS304 (thickness 20 mm x width 1000 mm x length 1700 mm), four base materials equivalent to SM400 Partition (thickness 40mm×width 30mm[=T 5 ], the longitudinal dimension is adjusted to be aligned with the base material), and then the alumina-based adhesive as a release material such as figure 1 Stack as shown and store in a vacuum container. The contact surface between the base material and the joining material, and the surface to be the abutting surface between the base material and the spacer are cleaned in advance by grinding with an electric sand mill.

[0061] Next, the inside of the vacuum container was made into a vacuum environment with a pressure of 0.1 Pa, laser beam welding was performed, and an assembled slab was produced. The laser output of laser beam welding was set to 30 kW, the welding speed was set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com